Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Enamel Burner position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

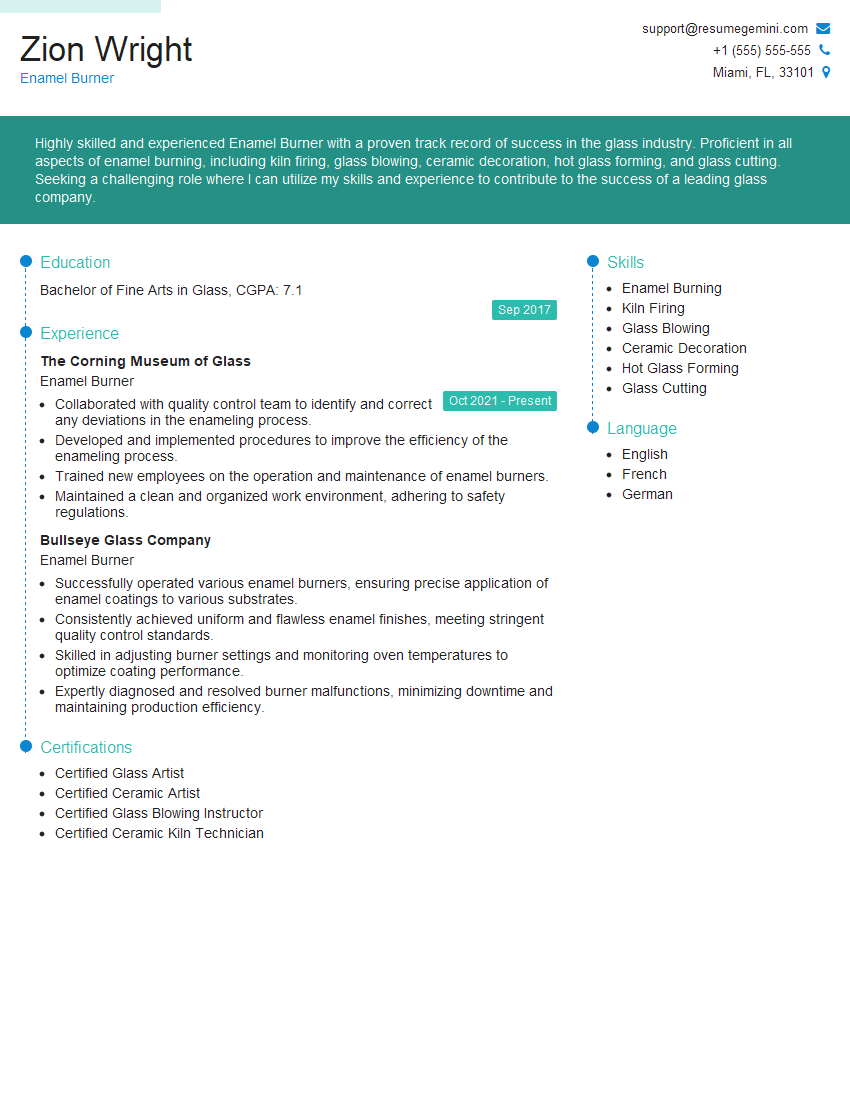

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Enamel Burner

1. What are the key factors that affect the quality of enamel burning?

The quality of enamel burning is primarily determined by:

- Temperature: Enamel must be fired at specific temperatures to achieve proper fusion and adhesion.

- Time: Adequate time must be provided for the enamel to fully react and bond to the metal surface.

- Atmosphere: The furnace atmosphere must be controlled to prevent oxidation and contamination.

- Surface preparation: The metal surface must be properly cleaned and treated to promote enamel adhesion.

- Enamel composition: The type of enamel used will determine its properties and influence the burning process.

2. How do you prepare the metal surface for enamel burning?

Preparing the metal surface for enamel burning involves multiple steps:

- Degreasing: Removing any oils, grease, or contaminants with solvents.

- Pickling: Immersing the metal in an acid bath to remove oxides and impurities.

- Sandblasting: Roughening the surface to improve enamel adhesion.

- Ultrasonic cleaning: Removing any remaining particles or contaminants.

- Nickel plating: Applying a layer of nickel to provide corrosion resistance and promote enamel bonding.

3. Describe the different types of enamel burning furnaces.

Enamel burning furnaces vary in their design and fuel source:

- Gas-fired furnaces: Use natural gas or propane as fuel and provide precise temperature control.

- Electric furnaces: Use electrical heating elements and offer a clean and environmentally friendly option.

- Radiant tube furnaces: Utilize infrared radiation to heat the enamel and reduce cycle times.

- Induction furnaces: Generate heat through electromagnetic induction, providing rapid and localized heating.

4. What are the common defects in enamel burning and how can they be prevented?

Defects in enamel burning include:

- Blisters: Caused by trapped gases or moisture in the enamel, which can be prevented by proper drying and firing.

- Crawling: Enamel receding from metal edges, which can be prevented by using the correct enamel thickness and firing profile.

- Fishscaling: Small flakes of enamel chipping off, which can be caused by overfiring or improper surface preparation.

- Pinholing: Small holes in the enamel, which can be prevented by proper enamel application and firing.

5. What are the industry standards for enamel burning and how do you ensure compliance?

Enamel burning industry standards include:

- ASTM A1644: Standard specification for porcelain enamel coatings on iron and steel.

- ISO 2078: International standard for ceramic enamels on metal surfaces.

- Regular testing and certification of enamel materials.

- Adherence to defined firing schedules and quality control procedures.

- Maintaining proper furnace settings and atmospheres.

- Continuous training and supervision of operators.

Compliance is ensured through:

6. Describe the maintenance and safety procedures for enamel burning operations.

Maintenance and safety procedures for enamel burning include:

- Furnace maintenance: Regular cleaning, calibration, and inspection of furnaces to ensure optimal performance and safety.

- Ventilation: Adequate ventilation to remove fumes and dust generated during enamel burning.

- Personal protective equipment (PPE): Use of appropriate PPE, such as respirators, gloves, and protective clothing, to prevent exposure to hazardous materials.

- Emergency procedures: Establishment of clear and documented procedures for handling emergencies, such as fire or gas leaks.

7. How do you optimize the enamel burning process for energy efficiency?

Optimizing the enamel burning process for energy efficiency involves:

- Energy-efficient furnaces: Selecting furnaces with high-efficiency burners and insulation.

- Optimized firing profiles: Using temperature and time schedules that minimize energy consumption while maintaining quality.

- Heat recovery systems: Utilizing waste heat from exhaust gases to preheat incoming air.

- Proper insulation: Ensuring that furnaces and ancillary equipment are adequately insulated to reduce heat loss.

8. What are the latest advancements in enamel burning technology?

Recent advancements in enamel burning technology include:

- Plasma-fired furnaces: Using plasma torches to provide faster and more precise heating.

- Laser-assisted enamel application: Utilizing lasers to create precise patterns and reduce material waste.

- Digital control systems: Implementing computerized systems to monitor and control the entire enamel burning process.

- Nano-enamels: Developing advanced enamels with improved properties, such as scratch resistance and durability.

9. How do you ensure the consistency and quality of enamel burning products?

Ensuring the consistency and quality of enamel burning products requires:

- Standardized processes: Establishing clear and detailed procedures for all aspects of the operation.

- Quality control testing: Regular testing of raw materials, enamel coatings, and finished products to verify compliance with specifications.

- Continuous improvement: Implementing a process for ongoing improvement, including feedback from customers and identification of areas for optimization.

- Training and certification: Providing training and certification to operators to ensure they are competent and follow best practices.

10. How do you troubleshoot common problems that may arise during enamel burning?

Troubleshooting common problems during enamel burning involves:

- Identifying the problem: Using visual inspection, testing, and process data to determine the root cause.

- Analyzing potential causes: Considering various factors such as temperature, firing time, enamel composition, and surface preparation.

- Implementing corrective actions: Making adjustments to the process or equipment based on the identified causes.

- Monitoring and evaluation: Tracking the effectiveness of the corrective actions and making further adjustments as needed.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Enamel Burner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Enamel Burner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Enamel Burner is a skilled professional responsible for applying enamel coatings to metal surfaces. They play a crucial role in ensuring the durability, aesthetic appeal, and safety of various products. Key job responsibilities include:

1. Surface Preparation

Preparing metal surfaces for enameling involves:

- Cleaning and degreasing surfaces to remove impurities

- Sandblasting or shot peening to create a rough surface for better enamel adhesion

2. Enamel Application

Applying enamel involves:

- Selecting the appropriate enamel type and color for the desired result

- Applying enamel to surfaces using spray guns or other equipment

- Ensuring even coverage and proper thickness

3. Curing and Inspection

Curing and inspecting enamel involves:

- Baking enameled surfaces in ovens to fuse the enamel to the metal

- Inspecting finished surfaces for defects such as chipping, peeling, or discoloration

- Adjusting application and curing parameters to improve enamel quality

4. Maintenance and Troubleshooting

Maintaining equipment and troubleshooting enamel defects involves:

- Cleaning and maintaining spray guns, ovens, and other equipment

- Identifying and resolving issues related to enamel application, curing, or adhesion

- Collaborating with other team members to optimize enamel production

Interview Tips

Preparing for an interview as an Enamel Burner requires a combination of technical knowledge and interpersonal skills. Here are some tips to help you ace the interview:

1. Research the Company and Position

Familiarize yourself with the company’s history, values, and specific enameling processes. Understand the job requirements and key responsibilities.

- Visit the company website and review their products and services

- Read industry news and articles to stay updated on enamel advancements

2. Highlight Relevant Skills and Experience

Emphasize your technical abilities, including surface preparation, enamel application, and quality control. Showcase any previous experience or training in enamel burning.

- Quantify your accomplishments using specific numbers and metrics

- Provide examples of your problem-solving skills and ability to troubleshoot enamel defects

3. Prepare for Common Interview Questions

Practice answering common interview questions tailored to the Enamel Burner role. These questions may include:

- “Tell me about your experience in enamel burning.”

- “How do you ensure the quality and consistency of enamel coatings?”

- “Describe a time you identified and resolved an enamel defect.”

4. Ask Thoughtful Questions

Asking insightful questions demonstrates your interest in the position and the company. Prepare questions about the company’s enamel production process, quality standards, or future plans.

- “What are the specific enamel coatings used in your products?”

- “How do you measure and control the thickness of enamel coatings?”

- “What is the company’s vision for the future of enamel technology?”

5. Dress Professionally and Be Punctual

First impressions matter. Dress appropriately and arrive on time for your interview. Maintain a positive and enthusiastic attitude throughout the interview process.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Enamel Burner interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!