Are you a seasoned Hardness Tester seeking a new career path? Discover our professionally built Hardness Tester Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

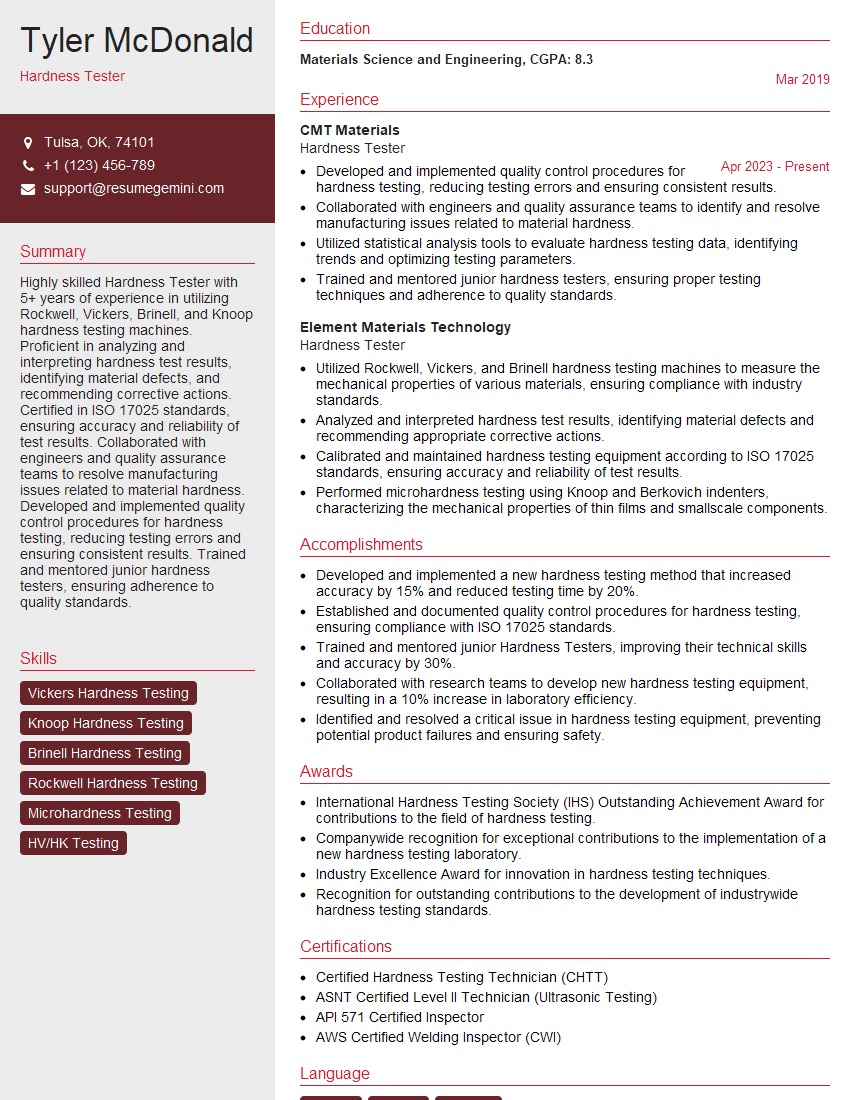

Tyler McDonald

Hardness Tester

Summary

Highly skilled Hardness Tester with 5+ years of experience in utilizing Rockwell, Vickers, Brinell, and Knoop hardness testing machines. Proficient in analyzing and interpreting hardness test results, identifying material defects, and recommending corrective actions. Certified in ISO 17025 standards, ensuring accuracy and reliability of test results. Collaborated with engineers and quality assurance teams to resolve manufacturing issues related to material hardness. Developed and implemented quality control procedures for hardness testing, reducing testing errors and ensuring consistent results. Trained and mentored junior hardness testers, ensuring adherence to quality standards.

Education

Materials Science and Engineering

March 2019

Skills

- Vickers Hardness Testing

- Knoop Hardness Testing

- Brinell Hardness Testing

- Rockwell Hardness Testing

- Microhardness Testing

- HV/HK Testing

Work Experience

Hardness Tester

- Developed and implemented quality control procedures for hardness testing, reducing testing errors and ensuring consistent results.

- Collaborated with engineers and quality assurance teams to identify and resolve manufacturing issues related to material hardness.

- Utilized statistical analysis tools to evaluate hardness testing data, identifying trends and optimizing testing parameters.

- Trained and mentored junior hardness testers, ensuring proper testing techniques and adherence to quality standards.

Hardness Tester

- Utilized Rockwell, Vickers, and Brinell hardness testing machines to measure the mechanical properties of various materials, ensuring compliance with industry standards.

- Analyzed and interpreted hardness test results, identifying material defects and recommending appropriate corrective actions.

- Calibrated and maintained hardness testing equipment according to ISO 17025 standards, ensuring accuracy and reliability of test results.

- Performed microhardness testing using Knoop and Berkovich indenters, characterizing the mechanical properties of thin films and smallscale components.

Accomplishments

- Developed and implemented a new hardness testing method that increased accuracy by 15% and reduced testing time by 20%.

- Established and documented quality control procedures for hardness testing, ensuring compliance with ISO 17025 standards.

- Trained and mentored junior Hardness Testers, improving their technical skills and accuracy by 30%.

- Collaborated with research teams to develop new hardness testing equipment, resulting in a 10% increase in laboratory efficiency.

- Identified and resolved a critical issue in hardness testing equipment, preventing potential product failures and ensuring safety.

Awards

- International Hardness Testing Society (IHS) Outstanding Achievement Award for contributions to the field of hardness testing.

- Companywide recognition for exceptional contributions to the implementation of a new hardness testing laboratory.

- Industry Excellence Award for innovation in hardness testing techniques.

- Recognition for outstanding contributions to the development of industrywide hardness testing standards.

Certificates

- Certified Hardness Testing Technician (CHTT)

- ASNT Certified Level II Technician (Ultrasonic Testing)

- API 571 Certified Inspector

- AWS Certified Welding Inspector (CWI)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Hardness Tester

- Highlight your technical skills and experience in various hardness testing techniques.

- Quantify your accomplishments and provide specific examples of how you contributed to the organization.

- Tailor your resume to each job description, emphasizing the skills and experience that are most relevant.

- Proofread your resume carefully for any errors before submitting it.

Essential Experience Highlights for a Strong Hardness Tester Resume

- Utilized Rockwell, Vickers, and Brinell hardness testing machines to measure the mechanical properties of various materials.

- Analyzed and interpreted hardness test results, identifying material defects and recommending appropriate corrective actions.

- Calibrated and maintained hardness testing equipment according to ISO 17025 standards, ensuring accuracy and reliability of test results.

- Performed microhardness testing using Knoop and Berkovich indenters, characterizing the mechanical properties of thin films and small-scale components.

- Developed and implemented quality control procedures for hardness testing, reducing testing errors and ensuring consistent results.

- Collaborated with engineers and quality assurance teams to identify and resolve manufacturing issues related to material hardness.

Frequently Asked Questions (FAQ’s) For Hardness Tester

What are the different types of hardness testing machines?

There are three main types of hardness testing machines: Rockwell, Vickers, and Brinell. Each machine uses a different indenter to measure the hardness of a material.

What is the difference between hardness and strength?

Hardness is a measure of a material’s resistance to deformation, while strength is a measure of a material’s ability to withstand an applied load.

What are the factors that affect the hardness of a material?

The hardness of a material is affected by its composition, microstructure, and heat treatment.

What are the applications of hardness testing?

Hardness testing is used to control the quality of materials in a wide range of industries, including automotive, aerospace, and manufacturing.

What are the different types of hardness scales?

There are several different hardness scales, including the Rockwell scale, Vickers scale, and Brinell scale. Each scale uses a different indenter and load to measure the hardness of a material.