Are you a seasoned Processing Manager seeking a new career path? Discover our professionally built Processing Manager Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

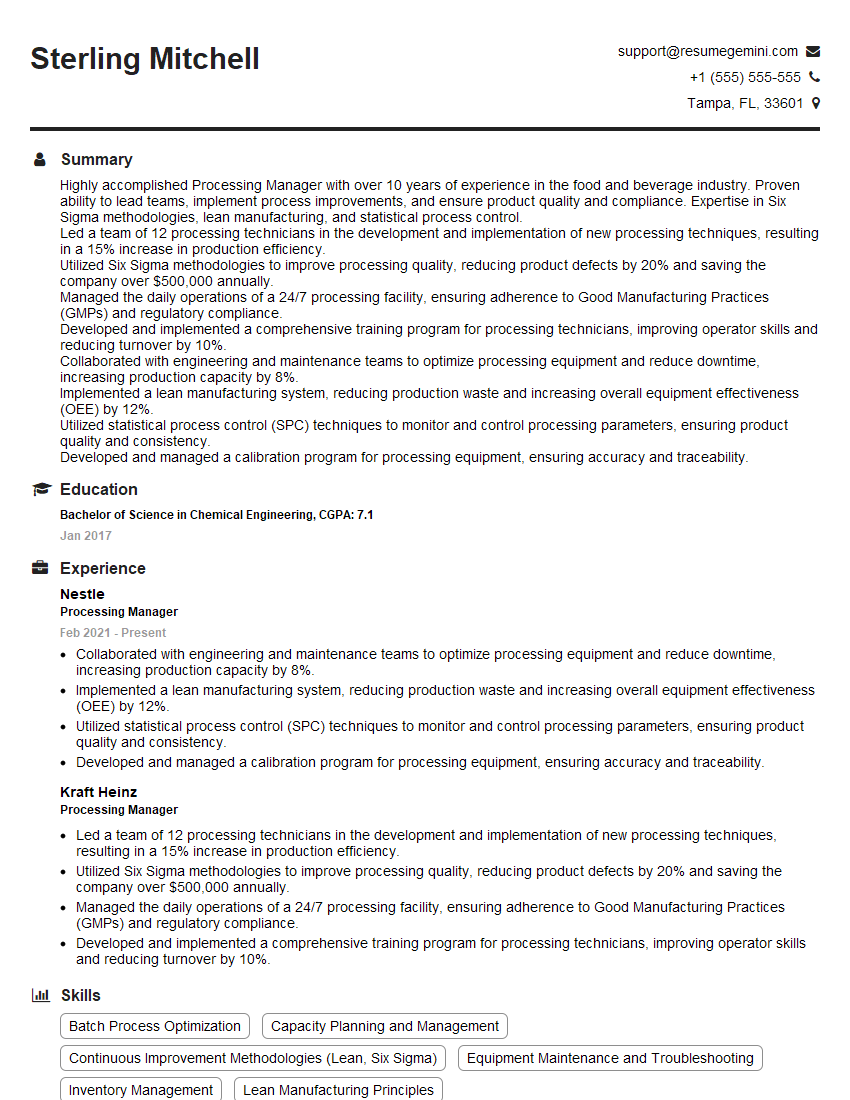

Sterling Mitchell

Processing Manager

Summary

Highly accomplished Processing Manager with over 10 years of experience in the food and beverage industry. Proven ability to lead teams, implement process improvements, and ensure product quality and compliance. Expertise in Six Sigma methodologies, lean manufacturing, and statistical process control.

Led a team of 12 processing technicians in the development and implementation of new processing techniques, resulting in a 15% increase in production efficiency.

Utilized Six Sigma methodologies to improve processing quality, reducing product defects by 20% and saving the company over $500,000 annually.

Managed the daily operations of a 24/7 processing facility, ensuring adherence to Good Manufacturing Practices (GMPs) and regulatory compliance.

Developed and implemented a comprehensive training program for processing technicians, improving operator skills and reducing turnover by 10%.

Collaborated with engineering and maintenance teams to optimize processing equipment and reduce downtime, increasing production capacity by 8%.

Implemented a lean manufacturing system, reducing production waste and increasing overall equipment effectiveness (OEE) by 12%.

Utilized statistical process control (SPC) techniques to monitor and control processing parameters, ensuring product quality and consistency.

Developed and managed a calibration program for processing equipment, ensuring accuracy and traceability.

Education

Bachelor of Science in Chemical Engineering

January 2017

Skills

- Batch Process Optimization

- Capacity Planning and Management

- Continuous Improvement Methodologies (Lean, Six Sigma)

- Equipment Maintenance and Troubleshooting

- Inventory Management

- Lean Manufacturing Principles

Work Experience

Processing Manager

- Collaborated with engineering and maintenance teams to optimize processing equipment and reduce downtime, increasing production capacity by 8%.

- Implemented a lean manufacturing system, reducing production waste and increasing overall equipment effectiveness (OEE) by 12%.

- Utilized statistical process control (SPC) techniques to monitor and control processing parameters, ensuring product quality and consistency.

- Developed and managed a calibration program for processing equipment, ensuring accuracy and traceability.

Processing Manager

- Led a team of 12 processing technicians in the development and implementation of new processing techniques, resulting in a 15% increase in production efficiency.

- Utilized Six Sigma methodologies to improve processing quality, reducing product defects by 20% and saving the company over $500,000 annually.

- Managed the daily operations of a 24/7 processing facility, ensuring adherence to Good Manufacturing Practices (GMPs) and regulatory compliance.

- Developed and implemented a comprehensive training program for processing technicians, improving operator skills and reducing turnover by 10%.

Accomplishments

- Led a crossfunctional team to implement a process automation solution, resulting in a 20% increase in production efficiency

- Developed and implemented a quality control system that reduced product defects by 15%

- Successfully managed a complex manufacturing process with multiple shifts and over 100 employees

- Improved process efficiency by 10% through the implementation of lean manufacturing principles

- Led a team that developed a new process for manufacturing a complex product, reducing production time by 25%

Awards

- Industry Excellence Award for Outstanding Contributions to Process Optimization

- Recognition for Exceptional Leadership in Process Improvement and Innovation

- Industry Award for Best Practices in Process Management and Control

- Recognition for Innovation in Process Design and Development

Certificates

- Certified Manufacturing Professional (CMP)

- Certified Production and Inventory Manager (CPIM)

- Certified Six Sigma Green Belt (CSSGB)

- Quality Auditor (QA)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Processing Manager

- Quantify your accomplishments and provide specific metrics to demonstrate your impact.

- Highlight your expertise in lean manufacturing, Six Sigma, and other process improvement methodologies.

- Emphasize your ability to lead and motivate a team in a fast-paced environment.

- Showcase your knowledge of regulatory compliance and quality assurance best practices.

- Tailor your resume to the specific job requirements and company culture.

Essential Experience Highlights for a Strong Processing Manager Resume

- Lead and motivate a team of processing technicians in the execution of daily operations.

- Implement process improvements to enhance efficiency, reduce costs, and improve product quality.

- Ensure compliance with Good Manufacturing Practices (GMPs) and regulatory requirements.

- Collaborate with engineering and maintenance teams to optimize equipment performance and minimize downtime.

- Develop and implement training programs to enhance operator skills and knowledge.

- Monitor and control processing parameters using statistical process control (SPC) techniques to ensure product quality.

- Manage inventory levels and ensure the availability of raw materials and supplies.

Frequently Asked Questions (FAQ’s) For Processing Manager

What are the key responsibilities of a Processing Manager?

The key responsibilities of a Processing Manager include leading and motivating a team of processing technicians, implementing process improvements, ensuring compliance with GMPs and regulatory requirements, collaborating with engineering and maintenance teams, developing and implementing training programs, monitoring and controlling processing parameters, and managing inventory levels.

What qualifications are needed to become a Processing Manager?

To become a Processing Manager, you typically need a bachelor’s degree in chemical engineering, food science, or a related field, as well as several years of experience in the food and beverage industry. Strong leadership, communication, and problem-solving skills are also essential.

What are the career prospects for Processing Managers?

Processing Managers can advance to more senior roles in the food and beverage industry, such as Plant Manager, Production Manager, or Quality Assurance Manager. They may also pursue careers in consulting or academia.

What are the challenges faced by Processing Managers?

Processing Managers face a number of challenges, including maintaining product quality and consistency, meeting production targets, and ensuring compliance with regulatory requirements. They must also be able to lead and motivate a team of employees in a fast-paced environment.

What is the salary range for Processing Managers?

The salary range for Processing Managers varies depending on their experience, education, and the size and location of the company they work for. According to Salary.com, the median salary for Processing Managers in the United States is around $85,000 per year.

What are the benefits of working as a Processing Manager?

The benefits of working as a Processing Manager include a competitive salary, opportunities for career advancement, and the chance to make a significant impact on the food and beverage industry.