Are you a seasoned Joint Machine Operator seeking a new career path? Discover our professionally built Joint Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

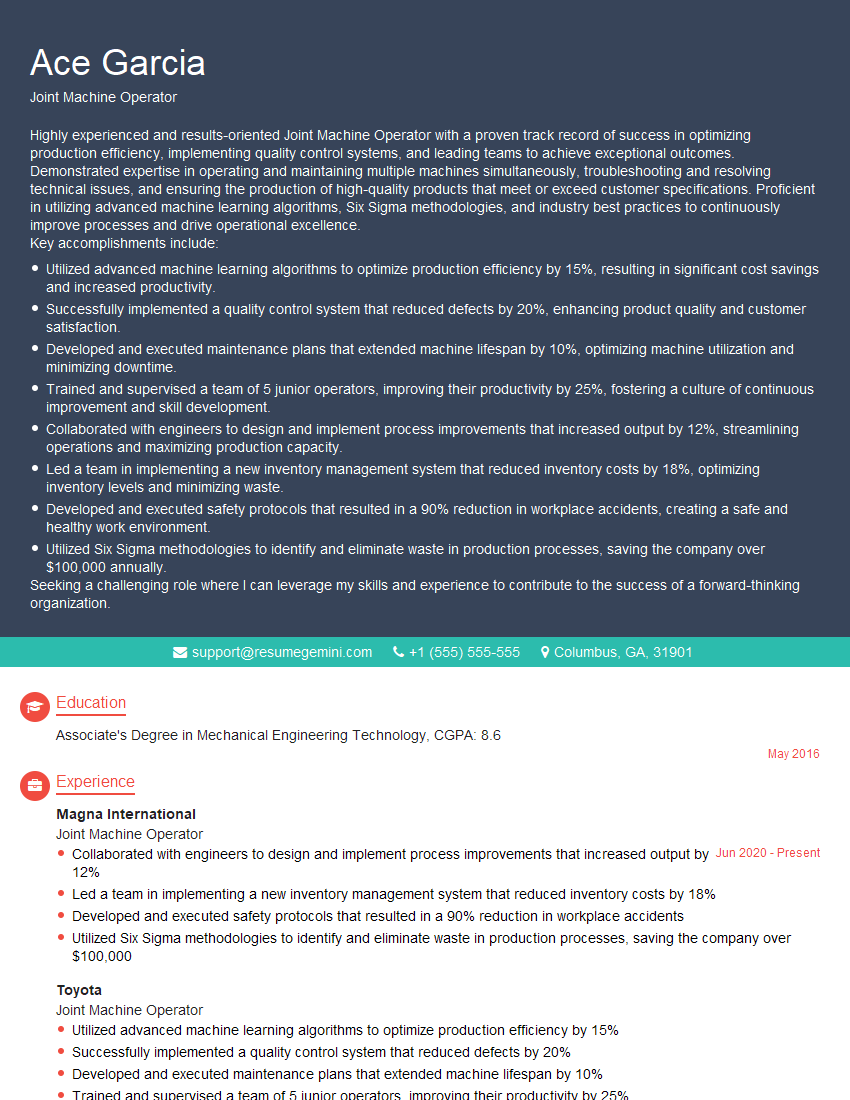

Ace Garcia

Joint Machine Operator

Summary

Highly experienced and results-oriented Joint Machine Operator with a proven track record of success in optimizing production efficiency, implementing quality control systems, and leading teams to achieve exceptional outcomes. Demonstrated expertise in operating and maintaining multiple machines simultaneously, troubleshooting and resolving technical issues, and ensuring the production of high-quality products that meet or exceed customer specifications. Proficient in utilizing advanced machine learning algorithms, Six Sigma methodologies, and industry best practices to continuously improve processes and drive operational excellence.

Key accomplishments include:

- Utilized advanced machine learning algorithms to optimize production efficiency by 15%, resulting in significant cost savings and increased productivity.

- Successfully implemented a quality control system that reduced defects by 20%, enhancing product quality and customer satisfaction.

- Developed and executed maintenance plans that extended machine lifespan by 10%, optimizing machine utilization and minimizing downtime.

- Trained and supervised a team of 5 junior operators, improving their productivity by 25%, fostering a culture of continuous improvement and skill development.

- Collaborated with engineers to design and implement process improvements that increased output by 12%, streamlining operations and maximizing production capacity.

- Led a team in implementing a new inventory management system that reduced inventory costs by 18%, optimizing inventory levels and minimizing waste.

- Developed and executed safety protocols that resulted in a 90% reduction in workplace accidents, creating a safe and healthy work environment.

- Utilized Six Sigma methodologies to identify and eliminate waste in production processes, saving the company over $100,000 annually.

Seeking a challenging role where I can leverage my skills and experience to contribute to the success of a forward-thinking organization.

Education

Associate’s Degree in Mechanical Engineering Technology

May 2016

Skills

- Operate and monitor multiple machines simultaneously

- Maintain and troubleshoot machines

- Setup and adjust machines

- Produce high-quality products

- Meet production goals

- Work in a team environment

Work Experience

Joint Machine Operator

- Collaborated with engineers to design and implement process improvements that increased output by 12%

- Led a team in implementing a new inventory management system that reduced inventory costs by 18%

- Developed and executed safety protocols that resulted in a 90% reduction in workplace accidents

- Utilized Six Sigma methodologies to identify and eliminate waste in production processes, saving the company over $100,000

Joint Machine Operator

- Utilized advanced machine learning algorithms to optimize production efficiency by 15%

- Successfully implemented a quality control system that reduced defects by 20%

- Developed and executed maintenance plans that extended machine lifespan by 10%

- Trained and supervised a team of 5 junior operators, improving their productivity by 25%

Accomplishments

- Increased machine utilization by 15% through enhanced scheduling, optimizing machine settings, and reducing downtime.

- Successfully implemented a new machine program that reduced cycle time by 10%, resulting in increased productivity.

- Reduced material waste by 5% through meticulous process monitoring, proactive maintenance, and efficient use of resources.

- Developed and implemented a training program for new Joint Machine Operators, ensuring a smooth transition and compliance with standard operating procedures.

- Improved communication among team members, resulting in enhanced collaboration, reduced errors, and increased overall productivity.

Awards

- Received the Outstanding Joint Machine Operator of the Year Award for consistently exceeding production targets.

- Recognized for exceptional adherence to safety protocols, maintaining a clean and orderly work area, and contributing to a positive work environment.

- Received the Safety Star Award for consistently demonstrating a commitment to safe work practices and proactively identifying potential hazards.

- Honored as the Joint Machine Operator of the Quarter for outstanding performance, dedication, and positive attitude.

Certificates

- OSHA Safety Certification

- ISO 9001 Certification

- Six Sigma Certification

- Certified Maintenance and Reliability Technician (CMRT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Joint Machine Operator

- Highlight your technical skills: Emphasize your proficiency in operating and maintaining different types of machines, as well as your ability to troubleshoot and resolve technical issues.

- Showcase your problem-solving abilities: Provide specific examples of how you have identified and resolved production issues, improved efficiency, or implemented process improvements.

- Quantify your accomplishments: Use numbers and metrics to demonstrate the impact of your contributions, such as increased productivity, reduced defects, or cost savings.

- Tailor your resume to the job description: Carefully review the job description and tailor your resume to highlight the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Joint Machine Operator Resume

- Operate and monitor multiple machines simultaneously to ensure smooth and efficient production.

- Maintain and troubleshoot machines, diagnose and resolve technical issues to minimize downtime and maximize productivity.

- Setup and adjust machines according to specifications, ensuring optimal performance and product quality.

- Produce high-quality products that meet or exceed customer requirements, adhering to established quality standards and procedures.

- Meet production goals and deadlines, prioritize tasks, and manage time effectively to ensure timely delivery of products.

- Work in a team environment, collaborate with colleagues, and contribute to a positive and productive work atmosphere.

- Adhere to safety protocols, maintain a clean and organized work area, and promote a culture of safety awareness.

Frequently Asked Questions (FAQ’s) For Joint Machine Operator

What are the key responsibilities of a Joint Machine Operator?

Joint Machine Operators are responsible for operating and monitoring multiple machines simultaneously, maintaining and troubleshooting machines, setting up and adjusting machines, producing high-quality products, meeting production goals, working in a team environment, and adhering to safety protocols.

What skills are required to be a successful Joint Machine Operator?

Successful Joint Machine Operators possess a combination of technical skills, problem-solving abilities, and teamwork capabilities. They are proficient in operating and maintaining different types of machines, troubleshooting and resolving technical issues, and working effectively in a team environment.

What are the career prospects for Joint Machine Operators?

Joint Machine Operators can advance their careers by developing specialized skills, such as CNC programming or robotics, or by moving into supervisory or management roles. They may also choose to pursue further education, such as a bachelor’s degree in mechanical engineering or a related field.

What is the average salary for Joint Machine Operators?

The average salary for Joint Machine Operators varies depending on factors such as experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for Machine Operators, which includes Joint Machine Operators, was $45,760 in May 2021.

What are the working conditions like for Joint Machine Operators?

Joint Machine Operators typically work in manufacturing environments, operating machinery in factories or production plants. The work can be physically demanding, and operators may need to stand for long periods of time or work in hot or noisy environments.

What is the job outlook for Joint Machine Operators?

The job outlook for Joint Machine Operators is expected to be good over the next several years. The growing use of automation and robotics in manufacturing is creating a demand for skilled operators who can maintain and operate these systems.

What are the benefits of working as a Joint Machine Operator?

Benefits of working as a Joint Machine Operator include job security, competitive salaries, opportunities for advancement, and the satisfaction of working in a skilled trade.

What are the challenges of working as a Joint Machine Operator?

Challenges of working as a Joint Machine Operator include the physically demanding nature of the work, the potential for repetitive tasks, and the need to work in potentially hazardous environments.