Are you a seasoned Fabrication Machine Operator seeking a new career path? Discover our professionally built Fabrication Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

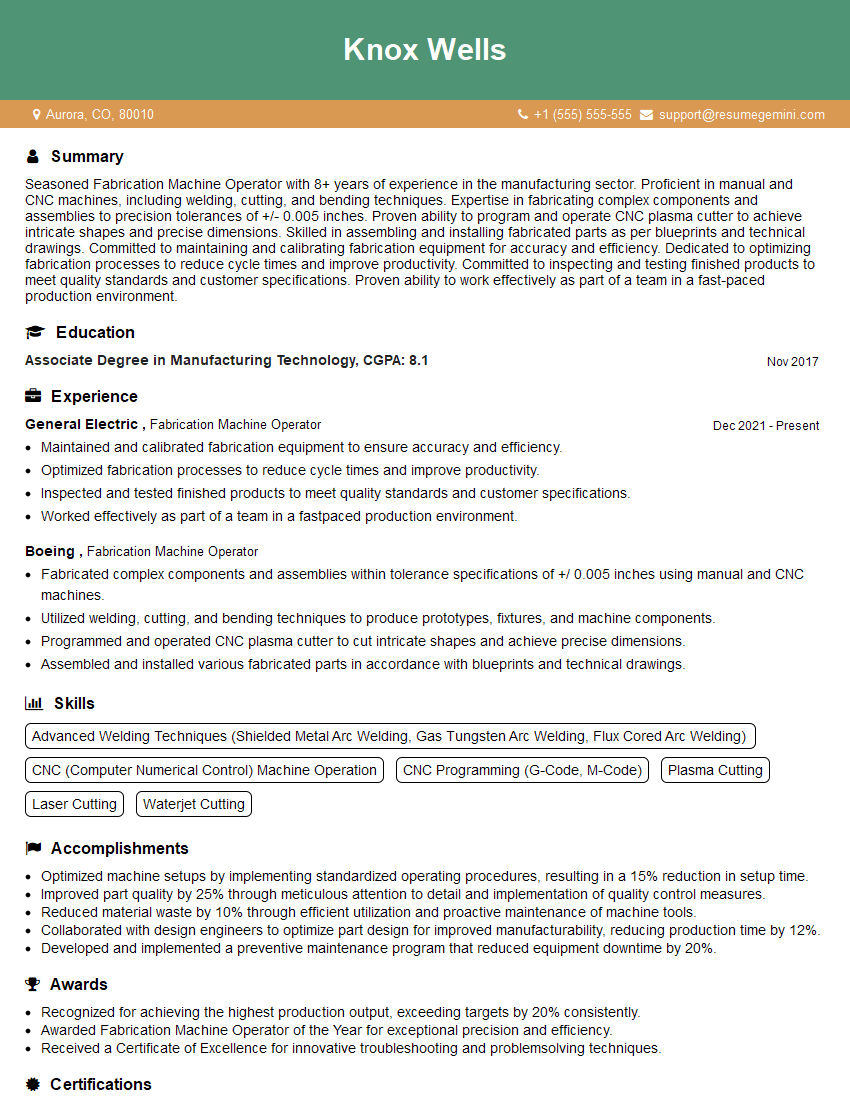

Knox Wells

Fabrication Machine Operator

Summary

Seasoned Fabrication Machine Operator with 8+ years of experience in the manufacturing sector. Proficient in manual and CNC machines, including welding, cutting, and bending techniques. Expertise in fabricating complex components and assemblies to precision tolerances of +/- 0.005 inches. Proven ability to program and operate CNC plasma cutter to achieve intricate shapes and precise dimensions. Skilled in assembling and installing fabricated parts as per blueprints and technical drawings. Committed to maintaining and calibrating fabrication equipment for accuracy and efficiency. Dedicated to optimizing fabrication processes to reduce cycle times and improve productivity. Committed to inspecting and testing finished products to meet quality standards and customer specifications. Proven ability to work effectively as part of a team in a fast-paced production environment.

Education

Associate Degree in Manufacturing Technology

November 2017

Skills

- Advanced Welding Techniques (Shielded Metal Arc Welding, Gas Tungsten Arc Welding, Flux Cored Arc Welding)

- CNC (Computer Numerical Control) Machine Operation

- CNC Programming (G-Code, M-Code)

- Plasma Cutting

- Laser Cutting

- Waterjet Cutting

Work Experience

Fabrication Machine Operator

- Maintained and calibrated fabrication equipment to ensure accuracy and efficiency.

- Optimized fabrication processes to reduce cycle times and improve productivity.

- Inspected and tested finished products to meet quality standards and customer specifications.

- Worked effectively as part of a team in a fastpaced production environment.

Fabrication Machine Operator

- Fabricated complex components and assemblies within tolerance specifications of +/ 0.005 inches using manual and CNC machines.

- Utilized welding, cutting, and bending techniques to produce prototypes, fixtures, and machine components.

- Programmed and operated CNC plasma cutter to cut intricate shapes and achieve precise dimensions.

- Assembled and installed various fabricated parts in accordance with blueprints and technical drawings.

Accomplishments

- Optimized machine setups by implementing standardized operating procedures, resulting in a 15% reduction in setup time.

- Improved part quality by 25% through meticulous attention to detail and implementation of quality control measures.

- Reduced material waste by 10% through efficient utilization and proactive maintenance of machine tools.

- Collaborated with design engineers to optimize part design for improved manufacturability, reducing production time by 12%.

- Developed and implemented a preventive maintenance program that reduced equipment downtime by 20%.

Awards

- Recognized for achieving the highest production output, exceeding targets by 20% consistently.

- Awarded Fabrication Machine Operator of the Year for exceptional precision and efficiency.

- Received a Certificate of Excellence for innovative troubleshooting and problemsolving techniques.

Certificates

- AWS (American Welding Society) Certified Welder

- ASME (American Society of Mechanical Engineers) Boiler and Pressure Vessel Code

- OSHA (Occupational Safety and Health Administration) Safety Training

- First Aid and CPR Certified

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Fabrication Machine Operator

- Highlight your experience and expertise in operating manual and CNC fabrication machines.

- Quantify your accomplishments whenever possible, using specific metrics and data to demonstrate your impact.

- Showcase your knowledge of fabrication techniques, materials, and quality control processes.

- Emphasize your ability to work independently and as part of a team in a fast-paced manufacturing environment.

Essential Experience Highlights for a Strong Fabrication Machine Operator Resume

- Fabricating complex components and assemblies to tolerance specifications using manual and CNC machines.

- Utilizing welding, cutting, and bending techniques to produce prototypes, fixtures, and machine components.

- Programming and operating CNC plasma cutter to cut intricate shapes and achieve precise dimensions.

- Assembling and installing various fabricated parts in accordance with blueprints and technical drawings.

- Maintaining and calibrating fabrication equipment to ensure accuracy and efficiency.

- Optimizing fabrication processes to reduce cycle times and improve productivity.

- Inspecting and testing finished products to meet quality standards and customer specifications.

Frequently Asked Questions (FAQ’s) For Fabrication Machine Operator

What is the role of a Fabrication Machine Operator?

A Fabrication Machine Operator is responsible for operating and maintaining fabrication equipment to produce parts and components for various industries. They use a combination of manual and CNC (Computer Numerical Control) machines to cut, bend, weld, and assemble materials to create complex shapes and structures.

What skills are required to become a Fabrication Machine Operator?

To become a Fabrication Machine Operator, you typically need a high school diploma or equivalent and some experience working in a manufacturing or fabrication environment. You should have strong mechanical aptitude, manual dexterity, and attention to detail. Proficiency in operating manual and CNC machines, as well as knowledge of fabrication techniques and materials, is also essential.

What are the career prospects for a Fabrication Machine Operator?

Fabrication Machine Operators are in high demand in various industries, including manufacturing, construction, automotive, and aerospace. With experience and additional training, you can advance your career to become a Supervisor, a Quality Control Inspector, or a Manufacturing Engineer.

What is the work environment of a Fabrication Machine Operator?

Fabrication Machine Operators typically work in industrial settings, such as factories, workshops, or fabrication shops. The work can be physically demanding and may involve working with hazardous materials and equipment. Therefore, safety precautions and adherence to safety protocols are crucial.

What are the key responsibilities of a Fabrication Machine Operator?

Key responsibilities of a Fabrication Machine Operator include setting up, operating, and maintaining fabrication equipment, such as CNC machines, welding machines, and cutting machines. They interpret technical drawings and specifications to ensure accurate production of components and assemblies. Additionally, they perform quality control checks and ensure that finished products meet the required standards.

What are the challenges faced by a Fabrication Machine Operator?

Fabrication Machine Operators may face challenges related to working with complex machinery and hazardous materials. They need to be able to work independently and as part of a team, and meet tight deadlines while maintaining high levels of accuracy and quality. Continuous learning and staying updated with the latest advancements in fabrication techniques and technologies are also important.

What is the salary range for a Fabrication Machine Operator?

The salary range for a Fabrication Machine Operator can vary depending on factors such as experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for Machinists and Tool and Die Makers, which includes Fabrication Machine Operators, was around $48,240 in May 2021.