Are you a seasoned Production Broaching Machine Operator seeking a new career path? Discover our professionally built Production Broaching Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

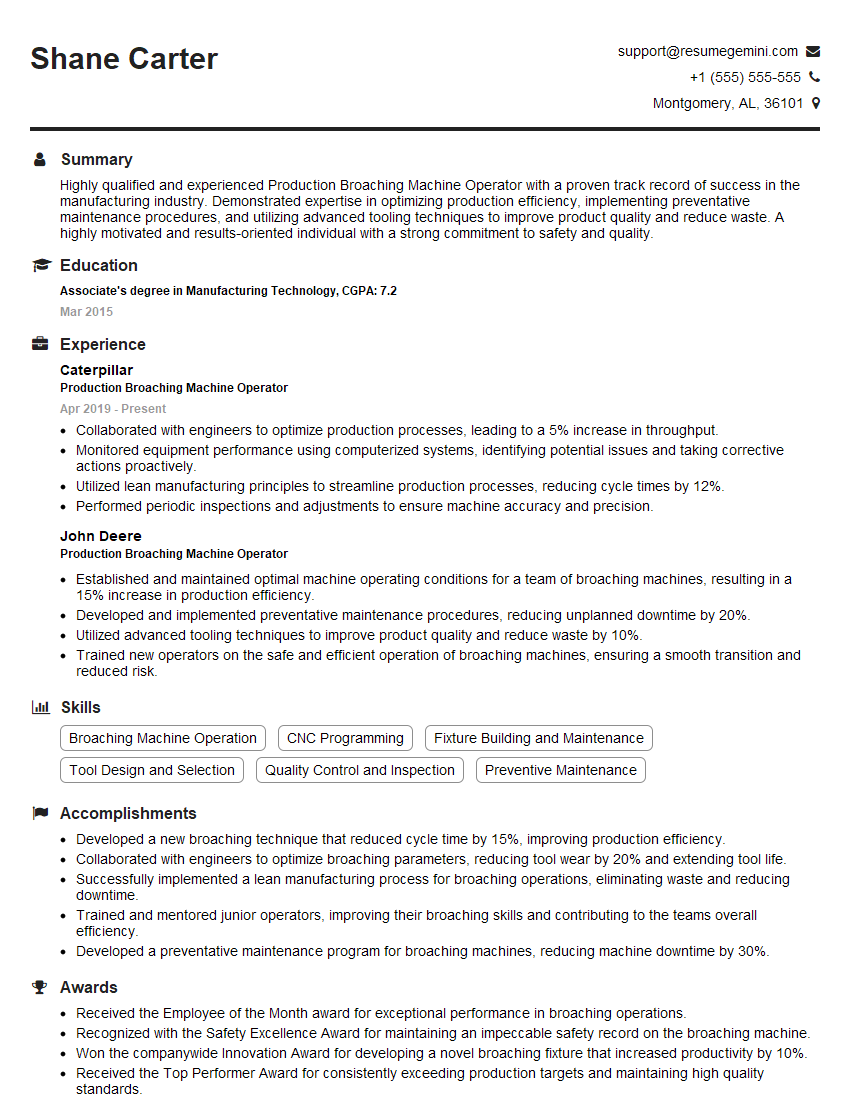

Shane Carter

Production Broaching Machine Operator

Summary

Highly qualified and experienced Production Broaching Machine Operator with a proven track record of success in the manufacturing industry. Demonstrated expertise in optimizing production efficiency, implementing preventative maintenance procedures, and utilizing advanced tooling techniques to improve product quality and reduce waste. A highly motivated and results-oriented individual with a strong commitment to safety and quality.

Education

Associate’s degree in Manufacturing Technology

March 2015

Skills

- Broaching Machine Operation

- CNC Programming

- Fixture Building and Maintenance

- Tool Design and Selection

- Quality Control and Inspection

- Preventive Maintenance

Work Experience

Production Broaching Machine Operator

- Collaborated with engineers to optimize production processes, leading to a 5% increase in throughput.

- Monitored equipment performance using computerized systems, identifying potential issues and taking corrective actions proactively.

- Utilized lean manufacturing principles to streamline production processes, reducing cycle times by 12%.

- Performed periodic inspections and adjustments to ensure machine accuracy and precision.

Production Broaching Machine Operator

- Established and maintained optimal machine operating conditions for a team of broaching machines, resulting in a 15% increase in production efficiency.

- Developed and implemented preventative maintenance procedures, reducing unplanned downtime by 20%.

- Utilized advanced tooling techniques to improve product quality and reduce waste by 10%.

- Trained new operators on the safe and efficient operation of broaching machines, ensuring a smooth transition and reduced risk.

Accomplishments

- Developed a new broaching technique that reduced cycle time by 15%, improving production efficiency.

- Collaborated with engineers to optimize broaching parameters, reducing tool wear by 20% and extending tool life.

- Successfully implemented a lean manufacturing process for broaching operations, eliminating waste and reducing downtime.

- Trained and mentored junior operators, improving their broaching skills and contributing to the teams overall efficiency.

- Developed a preventative maintenance program for broaching machines, reducing machine downtime by 30%.

Awards

- Received the Employee of the Month award for exceptional performance in broaching operations.

- Recognized with the Safety Excellence Award for maintaining an impeccable safety record on the broaching machine.

- Won the companywide Innovation Award for developing a novel broaching fixture that increased productivity by 10%.

- Received the Top Performer Award for consistently exceeding production targets and maintaining high quality standards.

Certificates

- Certified Broaching Machine Operator

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Production Broaching Machine Operator

- Highlight your technical skills and experience in broaching machine operation, CNC programming, and tool design.

- Quantify your accomplishments with specific metrics and data whenever possible.

- Emphasize your ability to improve production efficiency, reduce costs, and ensure quality.

- Showcase your commitment to safety and your knowledge of industry best practices.

Essential Experience Highlights for a Strong Production Broaching Machine Operator Resume

- Established and maintained optimal machine operating conditions for a team of broaching machines, resulting in a 15% increase in production efficiency.

- Developed and implemented preventative maintenance procedures, reducing unplanned downtime by 20%.

- Utilized advanced tooling techniques to improve product quality and reduce waste by 10%.

- Trained new operators on the safe and efficient operation of broaching machines, ensuring a smooth transition and reduced risk.

- Collaborated with engineers to optimize production processes, leading to a 5% increase in throughput.

- Monitored equipment performance using computerized systems, identifying potential issues and taking corrective actions proactively.

- Utilized lean manufacturing principles to streamline production processes, reducing cycle times by 12%.

Frequently Asked Questions (FAQ’s) For Production Broaching Machine Operator

What are the key skills required for a Production Broaching Machine Operator?

Key skills include broaching machine operation, CNC programming, fixture building and maintenance, tool design and selection, quality control and inspection, and preventive maintenance.

What are the primary responsibilities of a Production Broaching Machine Operator?

The primary responsibilities include operating and maintaining broaching machines, setting up and operating CNC programs, inspecting parts for quality, and performing preventive maintenance.

What are the career prospects for a Production Broaching Machine Operator?

With experience and additional training, Production Broaching Machine Operators can advance to positions such as CNC Programmer, Manufacturing Supervisor, or Quality Control Inspector.

What is the average salary for a Production Broaching Machine Operator?

According to the U.S. Bureau of Labor Statistics, the median annual salary for Production Broaching Machine Operators was \$44,290 in May 2021.

What are the working conditions for a Production Broaching Machine Operator?

Production Broaching Machine Operators typically work in manufacturing facilities, operating and maintaining broaching machines. The work can be physically demanding and may involve working with sharp tools and heavy equipment.

What are the educational requirements for a Production Broaching Machine Operator?

Most Production Broaching Machine Operators have a high school diploma or equivalent. Some employers may prefer candidates with an associate’s degree in manufacturing technology or a related field.

How can I become a Production Broaching Machine Operator?

To become a Production Broaching Machine Operator, you can complete a formal training program, apprentice under an experienced operator, or gain experience working in a manufacturing environment.