Are you a seasoned Cutting Torch Operator seeking a new career path? Discover our professionally built Cutting Torch Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

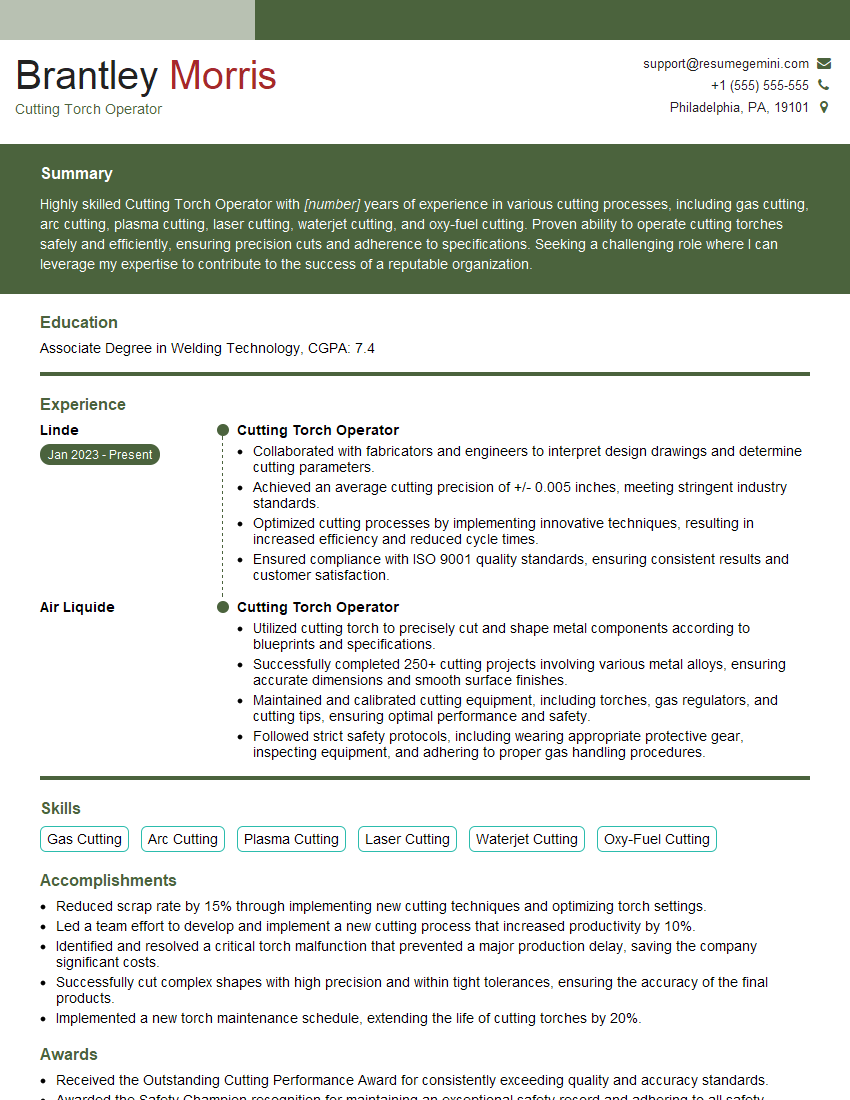

Brantley Morris

Cutting Torch Operator

Summary

Highly skilled Cutting Torch Operator with [number] years of experience in various cutting processes, including gas cutting, arc cutting, plasma cutting, laser cutting, waterjet cutting, and oxy-fuel cutting. Proven ability to operate cutting torches safely and efficiently, ensuring precision cuts and adherence to specifications. Seeking a challenging role where I can leverage my expertise to contribute to the success of a reputable organization.

Education

Associate Degree in Welding Technology

December 2018

Skills

- Gas Cutting

- Arc Cutting

- Plasma Cutting

- Laser Cutting

- Waterjet Cutting

- Oxy-Fuel Cutting

Work Experience

Cutting Torch Operator

- Collaborated with fabricators and engineers to interpret design drawings and determine cutting parameters.

- Achieved an average cutting precision of +/- 0.005 inches, meeting stringent industry standards.

- Optimized cutting processes by implementing innovative techniques, resulting in increased efficiency and reduced cycle times.

- Ensured compliance with ISO 9001 quality standards, ensuring consistent results and customer satisfaction.

Cutting Torch Operator

- Utilized cutting torch to precisely cut and shape metal components according to blueprints and specifications.

- Successfully completed 250+ cutting projects involving various metal alloys, ensuring accurate dimensions and smooth surface finishes.

- Maintained and calibrated cutting equipment, including torches, gas regulators, and cutting tips, ensuring optimal performance and safety.

- Followed strict safety protocols, including wearing appropriate protective gear, inspecting equipment, and adhering to proper gas handling procedures.

Accomplishments

- Reduced scrap rate by 15% through implementing new cutting techniques and optimizing torch settings.

- Led a team effort to develop and implement a new cutting process that increased productivity by 10%.

- Identified and resolved a critical torch malfunction that prevented a major production delay, saving the company significant costs.

- Successfully cut complex shapes with high precision and within tight tolerances, ensuring the accuracy of the final products.

- Implemented a new torch maintenance schedule, extending the life of cutting torches by 20%.

Awards

- Received the Outstanding Cutting Performance Award for consistently exceeding quality and accuracy standards.

- Awarded the Safety Champion recognition for maintaining an exceptional safety record and adhering to all safety protocols.

- Recognized for Operational Excellence for consistently meeting or exceeding production targets and maintaining high levels of accuracy.

- Received the Employee of the Quarter award for exceptional performance and dedication to the role.

Certificates

- Certified Welding Inspector (CWI)

- American Welding Society (AWS) Certified Welder

- National Institute for Certification in Engineering Technologies (NICET) Certified Fabricator

- International Association of Certified Home Inspectors (InterNACHI) Certified Home Inspector

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cutting Torch Operator

- Highlight your proficiency in various cutting techniques, including gas cutting, arc cutting, and plasma cutting.

- Quantify your experience by providing specific examples of projects or tasks where you demonstrated your skills.

- Emphasize your attention to detail and commitment to safety by mentioning your experience in inspecting cut materials and adhering to safety protocols.

- Showcase your adaptability and willingness to learn by highlighting your involvement in training programs or your pursuit of additional certifications.

- Proofread your resume carefully to ensure it is free of errors and reflects your professional abilities.

Essential Experience Highlights for a Strong Cutting Torch Operator Resume

- Operate cutting torches to cut and shape metal components according to blueprints and specifications.

- Select and adjust cutting parameters based on material type, thickness, and desired cut quality.

- Maintain cutting equipment, including torches, nozzles, and gas regulators, to ensure optimal performance.

- Inspect cut materials to verify accuracy and adherence to specifications.

- Follow safety protocols and wear appropriate personal protective equipment (PPE) while operating cutting torches.

- Collaborate with other team members to ensure efficient workflow and project completion.

- Stay updated on industry best practices and advancements in cutting technologies.

Frequently Asked Questions (FAQ’s) For Cutting Torch Operator

What are the different types of cutting methods used by Cutting Torch Operators?

Cutting Torch Operators commonly use gas cutting, arc cutting, plasma cutting, laser cutting, waterjet cutting, and oxy-fuel cutting.

What safety precautions should Cutting Torch Operators observe?

Cutting Torch Operators must wear appropriate personal protective equipment (PPE), follow established safety protocols, and ensure proper ventilation to minimize exposure to fumes and gases.

What is the educational background required to become a Cutting Torch Operator?

While formal education is not always necessary, many Cutting Torch Operators hold an Associate Degree in Welding Technology or a related field.

What are the career prospects for Cutting Torch Operators?

Cutting Torch Operators can advance to supervisory roles, specialize in specific cutting techniques, or pursue opportunities in related fields such as welding or fabrication.

What are the key skills required for Cutting Torch Operators?

Cutting Torch Operators should possess proficiency in cutting techniques, ability to read blueprints, attention to detail, and adherence to safety protocols.

What industries commonly employ Cutting Torch Operators?

Cutting Torch Operators find employment in various industries, including manufacturing, construction, shipbuilding, and automotive.

What is the work environment like for Cutting Torch Operators?

Cutting Torch Operators typically work in industrial settings, often exposed to noise, fumes, and potential hazards. They may work independently or as part of a team.

What are the physical demands of being a Cutting Torch Operator?

Cutting Torch Operators may need to stand for extended periods, lift heavy objects, and work in awkward positions.