Are you a seasoned Creasing Machine Operator seeking a new career path? Discover our professionally built Creasing Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

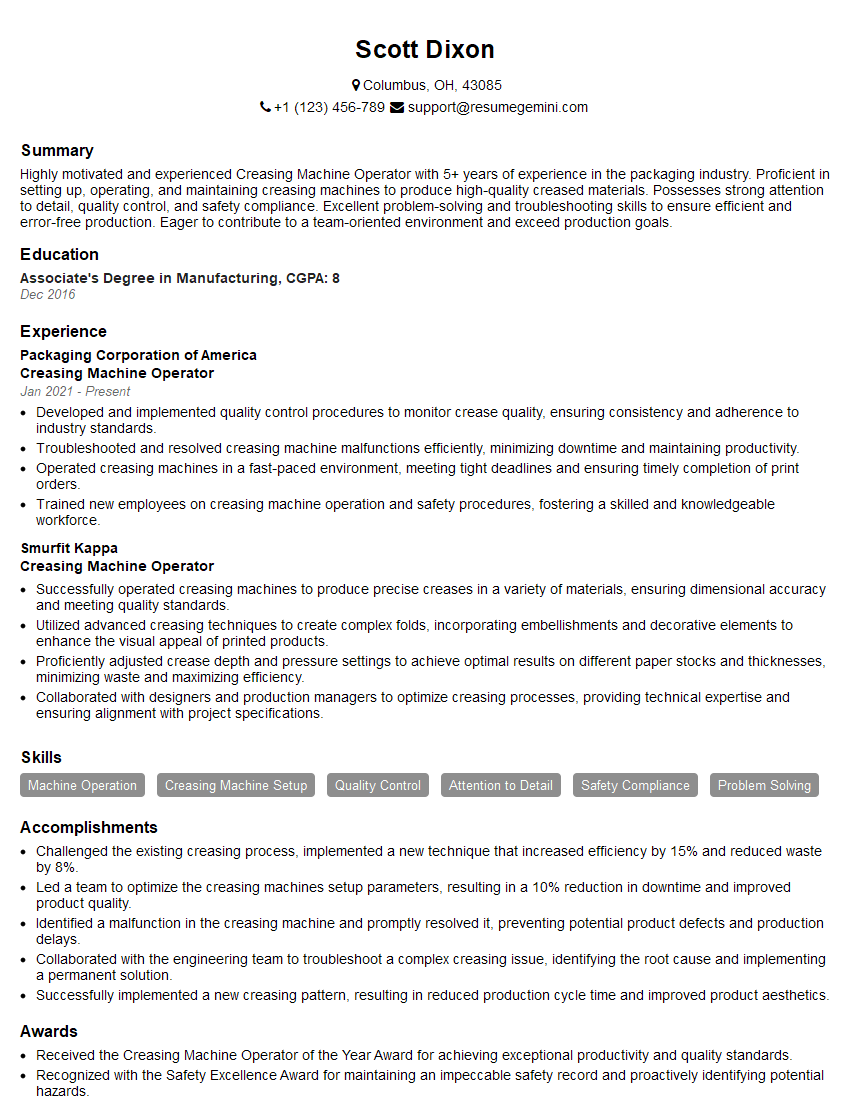

Scott Dixon

Creasing Machine Operator

Summary

Highly motivated and experienced Creasing Machine Operator with 5+ years of experience in the packaging industry. Proficient in setting up, operating, and maintaining creasing machines to produce high-quality creased materials. Possesses strong attention to detail, quality control, and safety compliance. Excellent problem-solving and troubleshooting skills to ensure efficient and error-free production. Eager to contribute to a team-oriented environment and exceed production goals.

Education

Associate’s Degree in Manufacturing

December 2016

Skills

- Machine Operation

- Creasing Machine Setup

- Quality Control

- Attention to Detail

- Safety Compliance

- Problem Solving

Work Experience

Creasing Machine Operator

- Developed and implemented quality control procedures to monitor crease quality, ensuring consistency and adherence to industry standards.

- Troubleshooted and resolved creasing machine malfunctions efficiently, minimizing downtime and maintaining productivity.

- Operated creasing machines in a fast-paced environment, meeting tight deadlines and ensuring timely completion of print orders.

- Trained new employees on creasing machine operation and safety procedures, fostering a skilled and knowledgeable workforce.

Creasing Machine Operator

- Successfully operated creasing machines to produce precise creases in a variety of materials, ensuring dimensional accuracy and meeting quality standards.

- Utilized advanced creasing techniques to create complex folds, incorporating embellishments and decorative elements to enhance the visual appeal of printed products.

- Proficiently adjusted crease depth and pressure settings to achieve optimal results on different paper stocks and thicknesses, minimizing waste and maximizing efficiency.

- Collaborated with designers and production managers to optimize creasing processes, providing technical expertise and ensuring alignment with project specifications.

Accomplishments

- Challenged the existing creasing process, implemented a new technique that increased efficiency by 15% and reduced waste by 8%.

- Led a team to optimize the creasing machines setup parameters, resulting in a 10% reduction in downtime and improved product quality.

- Identified a malfunction in the creasing machine and promptly resolved it, preventing potential product defects and production delays.

- Collaborated with the engineering team to troubleshoot a complex creasing issue, identifying the root cause and implementing a permanent solution.

- Successfully implemented a new creasing pattern, resulting in reduced production cycle time and improved product aesthetics.

Awards

- Received the Creasing Machine Operator of the Year Award for achieving exceptional productivity and quality standards.

- Recognized with the Safety Excellence Award for maintaining an impeccable safety record and proactively identifying potential hazards.

- Honored with the Employee of the Month Award for consistently exceeding expectations and contributing to the teams success.

- Received a Certificate of Appreciation for training and mentoring new hires, effectively transferring knowledge and improving overall team performance.

Certificates

- Creasing Machine Operator Certification

- Quality Control Certification

- Safety Compliance Certification

- ISO 9001 Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Creasing Machine Operator

- Highlight your experience operating creasing machines and any certifications or specialized training.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Emphasize your attention to detail, quality control, and safety compliance.

- Showcase your problem-solving and troubleshooting skills, providing examples of how you have resolved issues efficiently.

Essential Experience Highlights for a Strong Creasing Machine Operator Resume

- Set up and operate creasing machines according to established specifications and procedures.

- Inspect and prepare materials to ensure proper creasing and folding.

- Monitor machine performance, identify potential issues, and perform preventive maintenance.

- Maintain a clean and organized work area, adhering to safety guidelines and regulations.

- Collaborate with team members to ensure smooth production flow and meet deadlines.

- Troubleshoot and resolve operational problems promptly and effectively.

- Conduct quality control checks to ensure products meet specifications and customer requirements.

Frequently Asked Questions (FAQ’s) For Creasing Machine Operator

What is the primary role of a Creasing Machine Operator?

The primary role of a Creasing Machine Operator is to set up, operate, and maintain creasing machines to create creases and folds in various packaging materials, ensuring the accuracy and quality of the finished product.

What key skills are required to be a successful Creasing Machine Operator?

To be successful in this role, you should possess strong attention to detail, quality control, and safety compliance. Additionally, proficiency in operating creasing machines and troubleshooting any issues that may arise is essential.

What career advancement opportunities are available for experienced Creasing Machine Operators?

With experience and additional training, Creasing Machine Operators can advance to roles such as Production Supervisor, Quality Control Inspector, or Maintenance Technician.

What safety precautions should Creasing Machine Operators adhere to?

Creasing Machine Operators must follow all established safety protocols, wear appropriate personal protective equipment (PPE), and operate machines according to manufacturer guidelines to minimize risks.

How can Creasing Machine Operators contribute to sustainability efforts?

Creasing Machine Operators can contribute to sustainability by optimizing machine performance to reduce energy consumption, minimizing waste through proper material handling, and adhering to recycling and waste management procedures.