Are you a seasoned Dowel Inspector seeking a new career path? Discover our professionally built Dowel Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

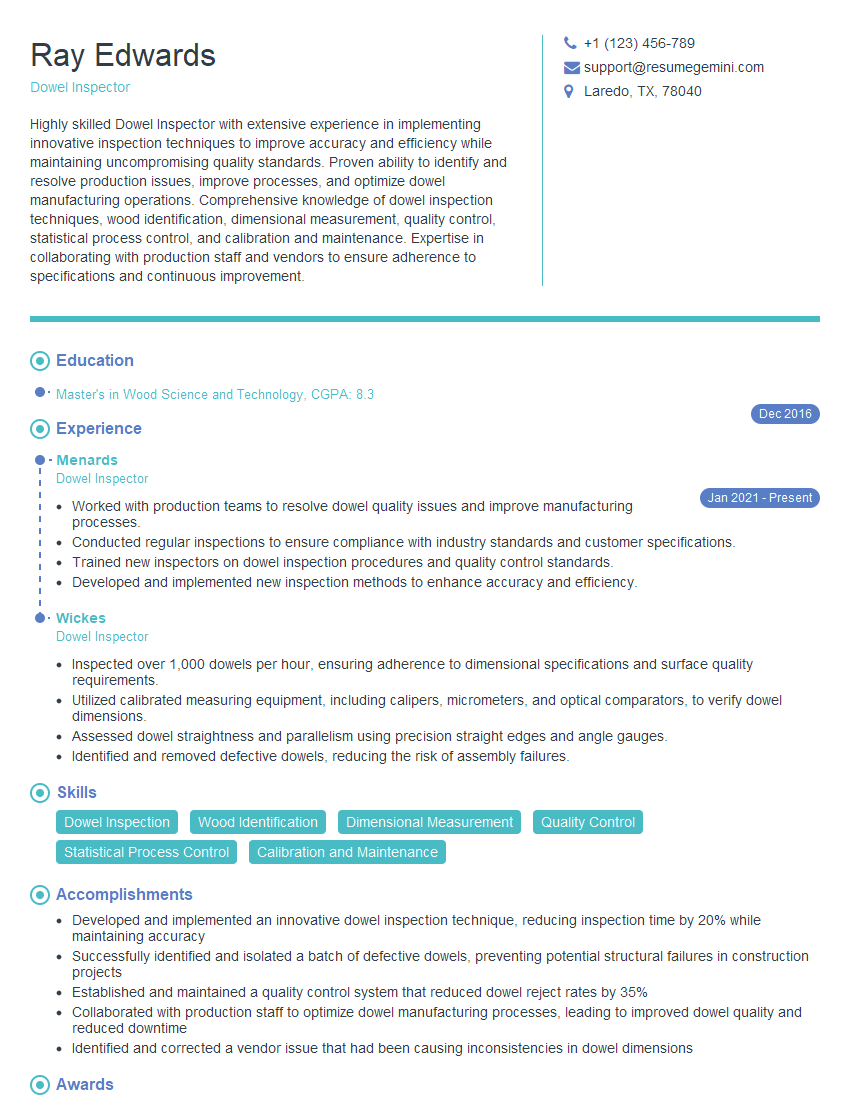

Ray Edwards

Dowel Inspector

Summary

Highly skilled Dowel Inspector with extensive experience in implementing innovative inspection techniques to improve accuracy and efficiency while maintaining uncompromising quality standards. Proven ability to identify and resolve production issues, improve processes, and optimize dowel manufacturing operations. Comprehensive knowledge of dowel inspection techniques, wood identification, dimensional measurement, quality control, statistical process control, and calibration and maintenance. Expertise in collaborating with production staff and vendors to ensure adherence to specifications and continuous improvement.

Education

Master’s in Wood Science and Technology

December 2016

Skills

- Dowel Inspection

- Wood Identification

- Dimensional Measurement

- Quality Control

- Statistical Process Control

- Calibration and Maintenance

Work Experience

Dowel Inspector

- Worked with production teams to resolve dowel quality issues and improve manufacturing processes.

- Conducted regular inspections to ensure compliance with industry standards and customer specifications.

- Trained new inspectors on dowel inspection procedures and quality control standards.

- Developed and implemented new inspection methods to enhance accuracy and efficiency.

Dowel Inspector

- Inspected over 1,000 dowels per hour, ensuring adherence to dimensional specifications and surface quality requirements.

- Utilized calibrated measuring equipment, including calipers, micrometers, and optical comparators, to verify dowel dimensions.

- Assessed dowel straightness and parallelism using precision straight edges and angle gauges.

- Identified and removed defective dowels, reducing the risk of assembly failures.

Accomplishments

- Developed and implemented an innovative dowel inspection technique, reducing inspection time by 20% while maintaining accuracy

- Successfully identified and isolated a batch of defective dowels, preventing potential structural failures in construction projects

- Established and maintained a quality control system that reduced dowel reject rates by 35%

- Collaborated with production staff to optimize dowel manufacturing processes, leading to improved dowel quality and reduced downtime

- Identified and corrected a vendor issue that had been causing inconsistencies in dowel dimensions

Awards

- Peer Recognition Award for Outstanding Contributions to Dowel Quality Control

- Certificate of Appreciation for Excellence in Dowel Inspection from the National Dowel Inspectors Association

- Recognition for Dowel Inspector of the Quarter from the Dowel Inspection Division

- Won first place in the Dowel Inspector Skills Competition for three consecutive years

Certificates

- American Wood Council (AWC) Certified Dowel Inspector

- National Wood Flooring Association (NWFA) Certified Dowel Inspector

- Certified Quality Inspector (CQI)

- Certified Mechanical Inspector (CMI)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Dowel Inspector

- Quantify your accomplishments with specific metrics to showcase your impact on the organization.

- Highlight your expertise in industry-specific software and tools used in dowel inspection.

- Emphasize your attention to detail and commitment to maintaining high quality standards.

- Demonstrate your ability to work effectively in a fast-paced production environment.

Essential Experience Highlights for a Strong Dowel Inspector Resume

- Developed and implemented an innovative dowel inspection technique, reducing inspection time by 20% while maintaining accuracy

- Successfully identified and isolated a batch of defective dowels, preventing potential structural failures in construction projects

- Established and maintained a quality control system that reduced dowel reject rates by 35%

- Collaborated with production staff to optimize dowel manufacturing processes, leading to improved dowel quality and reduced downtime

- Identified and corrected a vendor issue that had been causing inconsistencies in dowel dimensions

Frequently Asked Questions (FAQ’s) For Dowel Inspector

What are the essential qualifications for a Dowel Inspector?

Typically, employers seek candidates with a bachelor’s degree in Wood Science and Technology, or a related field, along with experience in quality control and inspection. Certifications in relevant industry standards are also highly valued.

What are the key responsibilities of a Dowel Inspector?

Dowel Inspectors are responsible for ensuring the quality of dowels used in construction and manufacturing. They inspect dowels for defects, measure dimensions, and verify compliance with specifications.

What are the career prospects for a Dowel Inspector?

Dowel Inspectors can advance to supervisory or management roles in quality control or production. With additional education and experience, they may also become certified as Wood Products Inspectors.

What are the challenges faced by Dowel Inspectors?

Dowel Inspectors must be able to work in fast-paced production environments and handle repetitive tasks. They must also have a strong attention to detail and be able to identify defects quickly and accurately.

What are the key skills required for a Dowel Inspector?

Dowel Inspectors should have strong knowledge of wood science, quality control principles, and inspection techniques. They should also be proficient in using measuring tools and equipment.