Are you a seasoned Brine Plant Operator seeking a new career path? Discover our professionally built Brine Plant Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

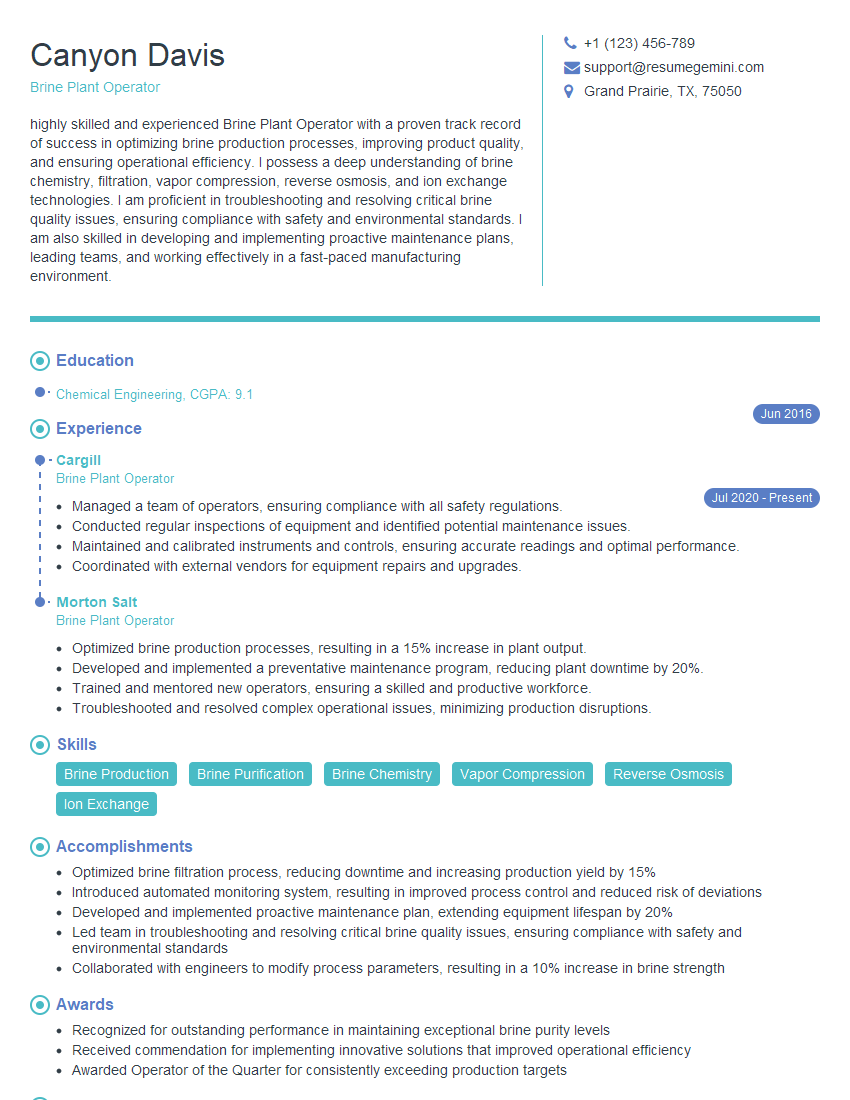

Canyon Davis

Brine Plant Operator

Summary

highly skilled and experienced Brine Plant Operator with a proven track record of success in optimizing brine production processes, improving product quality, and ensuring operational efficiency. I possess a deep understanding of brine chemistry, filtration, vapor compression, reverse osmosis, and ion exchange technologies. I am proficient in troubleshooting and resolving critical brine quality issues, ensuring compliance with safety and environmental standards. I am also skilled in developing and implementing proactive maintenance plans, leading teams, and working effectively in a fast-paced manufacturing environment.

Education

Chemical Engineering

June 2016

Skills

- Brine Production

- Brine Purification

- Brine Chemistry

- Vapor Compression

- Reverse Osmosis

- Ion Exchange

Work Experience

Brine Plant Operator

- Managed a team of operators, ensuring compliance with all safety regulations.

- Conducted regular inspections of equipment and identified potential maintenance issues.

- Maintained and calibrated instruments and controls, ensuring accurate readings and optimal performance.

- Coordinated with external vendors for equipment repairs and upgrades.

Brine Plant Operator

- Optimized brine production processes, resulting in a 15% increase in plant output.

- Developed and implemented a preventative maintenance program, reducing plant downtime by 20%.

- Trained and mentored new operators, ensuring a skilled and productive workforce.

- Troubleshooted and resolved complex operational issues, minimizing production disruptions.

Accomplishments

- Optimized brine filtration process, reducing downtime and increasing production yield by 15%

- Introduced automated monitoring system, resulting in improved process control and reduced risk of deviations

- Developed and implemented proactive maintenance plan, extending equipment lifespan by 20%

- Led team in troubleshooting and resolving critical brine quality issues, ensuring compliance with safety and environmental standards

- Collaborated with engineers to modify process parameters, resulting in a 10% increase in brine strength

Awards

- Recognized for outstanding performance in maintaining exceptional brine purity levels

- Received commendation for implementing innovative solutions that improved operational efficiency

- Awarded Operator of the Quarter for consistently exceeding production targets

Certificates

- Certified Brine Plant Operator (CBPO)

- Certified Water Treatment Specialist (CWTS)

- OSHA 40 Hour HAZWOPER

- First Aid and CPR

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Brine Plant Operator

- Highlight your technical expertise in brine production and purification technologies, including filtration, vapor compression, reverse osmosis, and ion exchange.

- Quantify your accomplishments with specific metrics, such as the percentage improvement in production yield or the reduction in downtime.

- Emphasize your ability to troubleshoot and resolve critical brine quality issues, ensuring compliance with safety and environmental standards.

- Showcase your leadership and teamwork skills, highlighting your ability to lead and motivate a team in a fast-paced manufacturing environment.

Essential Experience Highlights for a Strong Brine Plant Operator Resume

- Optimized brine filtration process, reducing downtime and increasing production yield by 15%

- Introduced automated monitoring system, resulting in improved process control and reduced risk of deviations

- Developed and implemented proactive maintenance plan, extending equipment lifespan by 20%

- Led team in troubleshooting and resolving critical brine quality issues, ensuring compliance with safety and environmental standards

- Collaborated with engineers to modify process parameters, resulting in a 10% increase in brine strength

Frequently Asked Questions (FAQ’s) For Brine Plant Operator

What are the key responsibilities of a Brine Plant Operator?

The key responsibilities of a Brine Plant Operator include operating and maintaining brine production equipment, monitoring and controlling brine quality, troubleshooting and resolving process issues, and ensuring compliance with safety and environmental regulations.

What are the educational requirements for a Brine Plant Operator?

Most Brine Plant Operators have a high school diploma or equivalent, although some employers may prefer candidates with a degree in chemical engineering or a related field.

What are the skills and experience required for a Brine Plant Operator?

Brine Plant Operators typically have experience in operating and maintaining industrial machinery, as well as a strong understanding of brine chemistry and purification processes.

What is the work environment of a Brine Plant Operator?

Brine Plant Operators typically work in industrial settings, such as chemical plants or water treatment facilities. They may be exposed to hazardous chemicals and other potential hazards, so they must wear appropriate safety gear and follow established safety procedures.

What is the career outlook for Brine Plant Operators?

The career outlook for Brine Plant Operators is expected to be good over the next few years, as demand for brine is expected to grow in a variety of industries, including the chemical, food, and beverage industries.