Feeling lost in a sea of interview questions? Landed that dream interview for Plasterer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Plasterer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

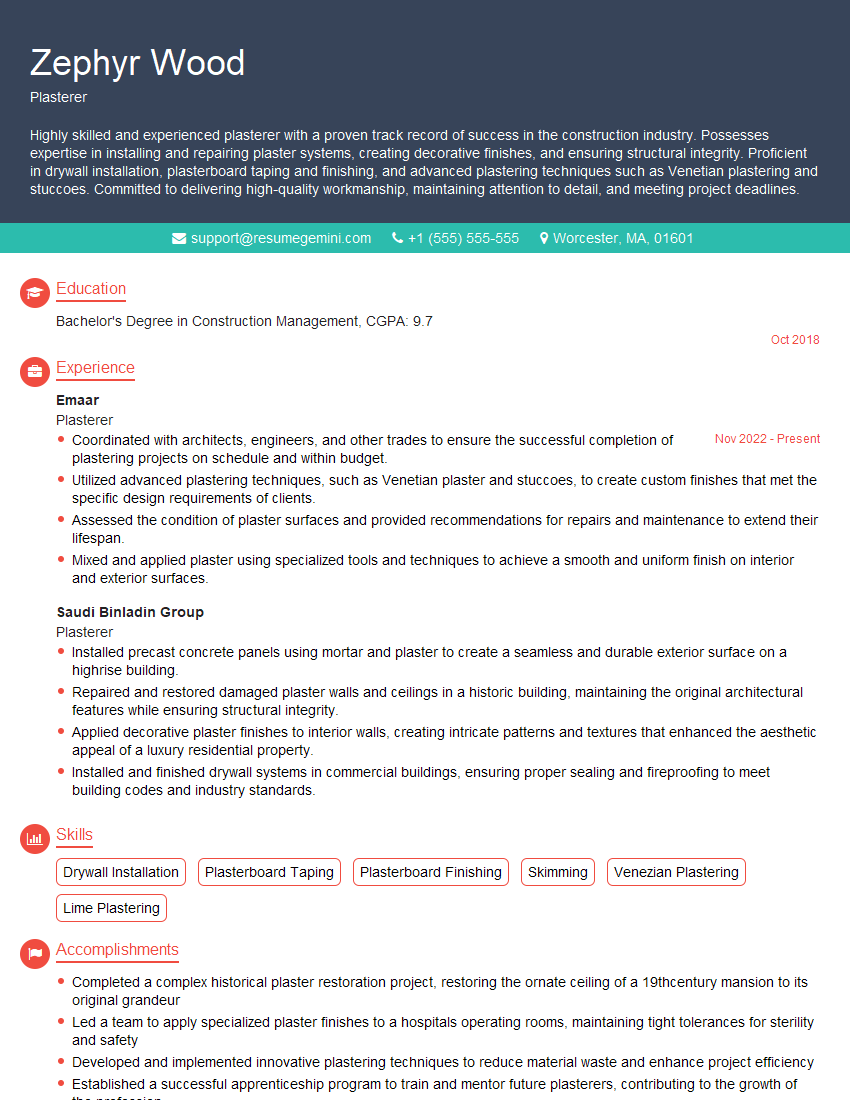

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Plasterer

1. What are the different types of plastering materials and their applications?

- Gypsum plaster: This is a versatile and widely used plaster material, suitable for both interior and exterior surfaces. It is composed of calcium sulfate dihydrate and provides a smooth and durable finish.

- Lime plaster: Made from hydrated lime, this plaster is known for its breathability and flexibility. It is commonly used in historical restoration projects and for exterior applications in damp environments.

- Cement plaster: Composed of cement, sand, and water, cement plaster is highly durable and resistant to moisture. It is often used for exterior walls, basements, and other areas where weather resistance is crucial.

- Polymer-modified plaster: This type of plaster incorporates polymer additives to enhance its strength, flexibility, and adhesion. It is ideal for areas subject to movement or vibration.

- Acrylic plaster: Made from acrylic resins, this plaster is highly weather-resistant and durable. It is often used as a textured finish for exterior facades.

2. Describe the steps involved in plastering a wall from preparation to finishing.

Preparation

- Preparing the surface by removing old plaster, cleaning, and making necessary repairs.

- Applying a bonding agent or scratch coat to enhance adhesion between the existing surface and the plaster.

Plastering

- Applying a base coat of plaster using a hawk and trowel, leveling it evenly over the surface.

- Allowing the base coat to set and harden.

- Applying a second coat of plaster, known as the floating coat, to achieve a smooth and uniform finish.

Finishing

- Smoothing the plaster surface using a trowel or sponge.

- Adding texture or decorative elements as required.

- Applying a sealer or paint to protect and enhance the surface.

3. How do you ensure the quality and durability of your plastering work?

- Proper surface preparation: Ensuring the surface is clean, sound, and adequately prepared helps promote good adhesion.

- Using high-quality materials: Selecting the right plaster material for the specific application and environment is crucial for durability.

- Mixing and applying the plaster correctly: Following the manufacturer’s instructions and using the proper ratios and techniques ensures optimal performance.

- Proper curing: Allowing the plaster to set and cure properly prevents cracking and premature deterioration.

- Applying protective coatings: Sealing or painting the plastered surface protects it from moisture, stains, and wear.

4. What techniques do you use to create different plaster finishes, such as smooth, textured, or decorative?

- Smooth finish: Using a trowel to smooth and level the plaster surface, achieving a uniform and polished appearance.

- Textured finish: Applying the plaster using a brush or sponge to create a variety of textures, such as knockdown, stipple, or sand swirl.

- Decorative finish: Incorporating decorative elements such as molding, carvings, or stenciling to enhance the aesthetic appeal.

5. How do you handle repairs and maintenance of plastered surfaces?

- Minor repairs: Filling small cracks or holes with patching compound and blending it seamlessly with the surrounding plaster.

- Larger repairs: Removing damaged plaster, repairing the underlying surface if necessary, and re-plastering the area to match the existing finish.

- Maintenance: Regularly cleaning and inspecting plastered surfaces, identifying and repairing any potential issues promptly to maintain their integrity.

6. What are some common problems that can arise during plastering and how do you resolve them?

- Cracking: Caused by factors such as poor surface preparation, improper mixing or application, or movement in the underlying structure. Resolved by repairing the cracks, addressing any underlying issues, and re-plastering.

- Blistering: Resulting from trapped air or moisture in the plaster. Resolved by removing the blisters, allowing for ventilation, and re-applying the plaster.

- Discoloration: Caused by impurities in the plaster, water stains, or other factors. Resolved by identifying the cause and treating the discoloration or replacing the affected area.

7. What safety precautions do you observe during plastering work?

- Wearing appropriate personal protective equipment (PPE), including gloves, eye protection, and a dust mask.

- Ensuring adequate ventilation in the work area to prevent inhalation of plaster dust.

- Using proper scaffolding or ladders for safe access to elevated areas.

- Handling plaster materials and tools carefully to minimize the risk of spills or injuries.

- Following safe mixing and application techniques to avoid chemical burns or other hazards.

8. How do you stay updated on new techniques and products in the plastering industry?

- Attending industry training and workshops.

- Reading trade publications and online resources.

- Consulting with manufacturers and suppliers for the latest product information.

- Networking with other plasterers and professionals.

- Experimenting with new techniques and materials to improve skills and knowledge.

9. What is your approach to working as part of a construction team?

- Communicating effectively with project managers, architects, and other tradespeople.

- Coordinating work schedules and ensuring timely completion of tasks.

- Understanding blueprints and specifications to ensure accurate execution.

- Maintaining a clean and organized work area.

- Contributing to a positive and collaborative work environment.

10. How do you handle situations where there are different opinions or conflicting requirements on a project?

- Listening actively to all perspectives and seeking clarification as needed.

- Evaluating the merits of each opinion and considering the project’s overall goals.

- Collaborating with the team to find mutually acceptable solutions.

- Communicating recommendations clearly and presenting supporting evidence when necessary.

- Remaining professional and respectful, even in situations of disagreement.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Plasterer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Plasterer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Plasterer

Plasterers play a crucial role in the construction industry, applying layers of plaster to walls, ceilings, and other surfaces to create smooth and durable finishes. Their key job responsibilities include:

1. Installing and Repairing Plaster Surfaces

Plasterers are responsible for applying, smoothing, and leveling plaster onto various surfaces. They repair existing plaster surfaces by filling holes, cracks, and imperfections, and ensure that the finished surface is smooth, straight, and free of defects.

2. Mixing and Applying Plaster

Plasterers mix plaster materials according to specified ratios and apply it using tools such as trowels and floats. They must have a keen eye for detail and the ability to control the thickness and consistency of the plaster to achieve the desired finish.

3. Applying Texture and Finishes

In addition to applying smooth plaster, plasterers can also create textured finishes using sponges, brushes, and other tools. They may also apply decorative details such as moldings and cornices to enhance the appearance of surfaces.

4. Working in Various Environments

Plasterers work in both interior and exterior environments, including residential, commercial, and historical buildings. They must be comfortable working on scaffolding, ladders, and at heights.

Interview Preparation Tips for Plasterers

Preparing thoroughly for a plasterer interview can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific plasterer position you are applying for. Learn about their projects, values, and areas of expertise. This demonstrates your interest and allows you to tailor your answers to the company’s needs.

2. Highlight Your Experience and Skills

In your resume and during the interview, emphasize your relevant experience in plastering. Quantify your accomplishments by providing specific examples of projects you have worked on, techniques you have mastered, and the quality of your finished work.

3. Practice Common Interview Questions

Prepare answers to common interview questions, such as:

- Tell me about your experience in plastering.

- What are the different types of plaster and when are they used?

- How do you ensure the quality of your plaster work?

4. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive on time for your interview. This shows that you respect the interviewer’s time and are serious about the position.

5. Be Enthusiastic and Ask Questions

Show the interviewer that you are enthusiastic about plastering and the company. Ask thoughtful questions about the job, the company, and the industry. This demonstrates your engagement and interest.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Plasterer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Plasterer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.