Are you gearing up for a career in Sheet Metal Work Furnace Installer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Sheet Metal Work Furnace Installer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

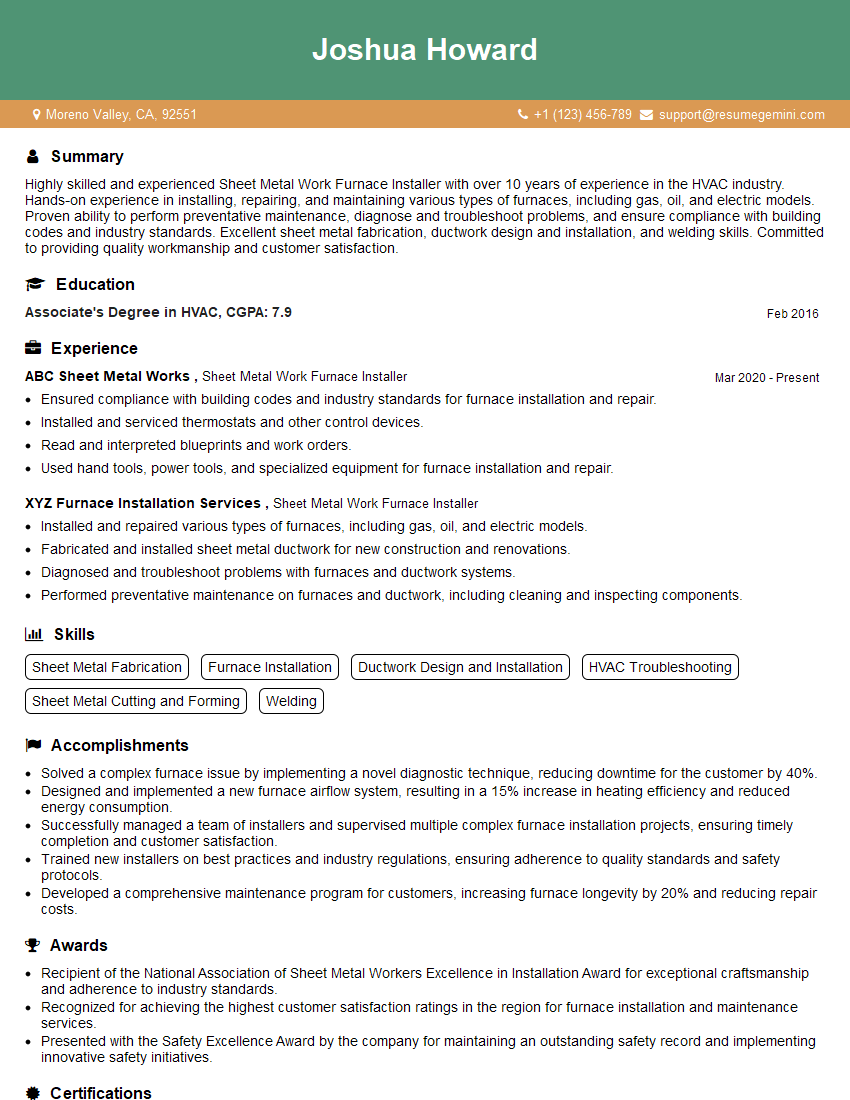

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Sheet Metal Work Furnace Installer

1. Can you describe the key steps involved in installing a gas furnace?

The key steps involved in installing a gas furnace are:

- Check local building codes and obtain necessary permits.

- Determine the location of the furnace and create a plan for installation.

- Install the furnace base and connect the gas line and electrical wiring.

- Hang the furnace unit on the base and secure it.

- Attach the ductwork and ensure proper airflow.

- Connect the thermostat and test the system for proper operation.

2. What are the different types of sheet metal used in furnace installation?

Cold-rolled steel

- Durable and resistant to corrosion.

- Used for ductwork, plenums, and other components.

Galvanized steel

- Coated with zinc for added corrosion resistance.

- Suitable for outdoor applications and areas with high humidity.

Stainless steel

- Highly resistant to corrosion and heat.

- Used for specialized applications, such as in commercial kitchens or industrial settings.

3. How do you ensure that the furnace is properly vented?

To ensure proper venting, I follow these steps:

- Check the manufacturer’s specifications for the required flue size and length.

- Install the vent pipe with the correct slope and clearances from combustible materials.

- Use the appropriate materials, such as PVC or metal, for the vent pipe.

- Test the venting system for proper airflow and draft.

4. What are the common problems you have encountered during furnace installation and how did you resolve them?

- Problem: Furnace not igniting Resolution: Checked gas supply, pilot light, and ignition system; replaced faulty components.

- Problem: Poor airflow Resolution: Inspected ductwork for obstructions, cleaned filters, and adjusted blower speed.

- Problem: Gas leaks Resolution: Used a leak detector to locate leaks; tightened connections and replaced damaged seals.

5. What are the safety precautions that you take when working with gas furnaces?

- Wear appropriate safety gear, including gloves and protective eyewear.

- Turn off the gas supply before working on the furnace.

- Use a gas detector to check for leaks before starting any repairs.

- Handle gas lines with care and use proper tools and fittings.

- Follow all manufacturer’s instructions and local building codes.

6. What tools and equipment do you use for furnace installation?

- Sheet metal shears

- Drill and driver

- Wrenches and pliers

- Level and measuring tape

- Safety glasses and gloves

7. How do you stay up-to-date with the latest developments and technologies in furnace installation?

- Attend industry workshops and seminars.

- Read trade publications and online resources.

- Consult with manufacturers and distributors.

- Participate in online forums and discussion groups.

8. What are the qualities of a successful Sheet Metal Work Furnace Installer?

- Strong technical skills in sheet metal fabrication and installation.

- Knowledge of gas and electrical systems.

- Attention to detail and precision.

- Problem-solving and troubleshooting abilities.

- Customer service and communication skills.

9. How do you handle challenges and unexpected situations during furnace installation?

- Assess the situation and identify potential solutions.

- Consult with experienced colleagues or the manufacturer for guidance.

- Use creative thinking and problem-solving skills to find practical solutions.

- Document any challenges and solutions for future reference.

10. Why are you interested in working as a Sheet Metal Work Furnace Installer with our company?

I am interested in working as a Sheet Metal Work Furnace Installer with your company because:

- Your company has a reputation for providing high-quality HVAC services.

- I am eager to contribute my skills and experience to your team.

- I am confident that I can be a valuable asset to your company and provide exceptional service to your customers.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Sheet Metal Work Furnace Installer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Sheet Metal Work Furnace Installer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Sheet Metal Work Furnace Installers fabricate, install, and maintain sheet metal components and systems for furnaces. Their primary responsibilities include:

1. Fabrication and Installation

Fabricate and assemble sheet metal components according to blueprints and specifications.

- Cut, bend, and shape sheet metal using hand tools and machines.

- Weld and join sheet metal components to form airtight and watertight seals.

- Install furnaces, ducts, and other sheet metal components in residential and commercial buildings.

2. Maintenance and Repair

Maintain and repair sheet metal systems to ensure optimal performance and longevity.

- Inspect and clean furnaces and ducts to prevent breakdowns and improve efficiency.

- Repair or replace damaged sheet metal components such as ducts, vents, and hoods.

- Adjust and calibrate furnace controls to optimize energy consumption and indoor air quality.

3. Troubleshooting and Problem-Solving

Troubleshoot and resolve issues related to sheet metal systems and furnace performance.

- Identify and diagnose problems based on symptoms and observations.

- Develop and implement solutions to fix leaks, improve airflow, and restore system functionality.

- Recommend preventive maintenance strategies to prolong the lifespan of sheet metal systems.

4. Teamwork and Communication

Work as part of a team to complete installation and maintenance projects.

- Communicate effectively with colleagues, supervisors, and clients.

- Maintain a clean and organized work environment.

- Adhere to safety regulations and standards.

Interview Tips

To ace an interview for a Sheet Metal Work Furnace Installer position, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s history, values, and current projects. Understand the specific requirements and responsibilities of the furnace installer role.

- Visit the company website, read industry publications, and connect with current or former employees on LinkedIn.

- Highlight in your answers how your skills and experience align with the company’s needs.

2. Showcase Your Technical Skills

Emphasize your proficiency in sheet metal fabrication and installation techniques, including cutting, bending, welding, and soldering. Discuss your knowledge of furnace systems and the importance of proper installation.

- Provide specific examples of projects where you have demonstrated your technical abilities.

- Quantify your accomplishments using metrics like the number of furnaces installed, customer satisfaction ratings, or cost savings achieved.

3. Highlight Your Troubleshooting Abilities

Discuss your approach to troubleshooting sheet metal and furnace problems, emphasizing your analytical skills and ability to identify and resolve complex issues.

- Describe a challenging situation where you successfully diagnosed and fixed a furnace malfunction.

- Explain your methods for testing and verifying system performance.

4. Emphasize Safety and Teamwork

Stress the importance of safety practices in sheet metal work and your adherence to industry standards. Highlight your experience working effectively in a team environment.

- Discuss your safety certifications and training programs.

- Share examples of how you have contributed to a safe and productive work environment.

5. Prepare Questions to Ask

Asking thoughtful questions demonstrates your interest in the position and the company. Prepare questions about the team structure, career advancement opportunities, and the company’s commitment to sustainability.

- Consider questions that are specific to the industry or the company’s operations.

- Asking questions shows that you are engaged in the interview and eager to learn more.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Sheet Metal Work Furnace Installer interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.