Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Production Troubleshooter interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Production Troubleshooter so you can tailor your answers to impress potential employers.

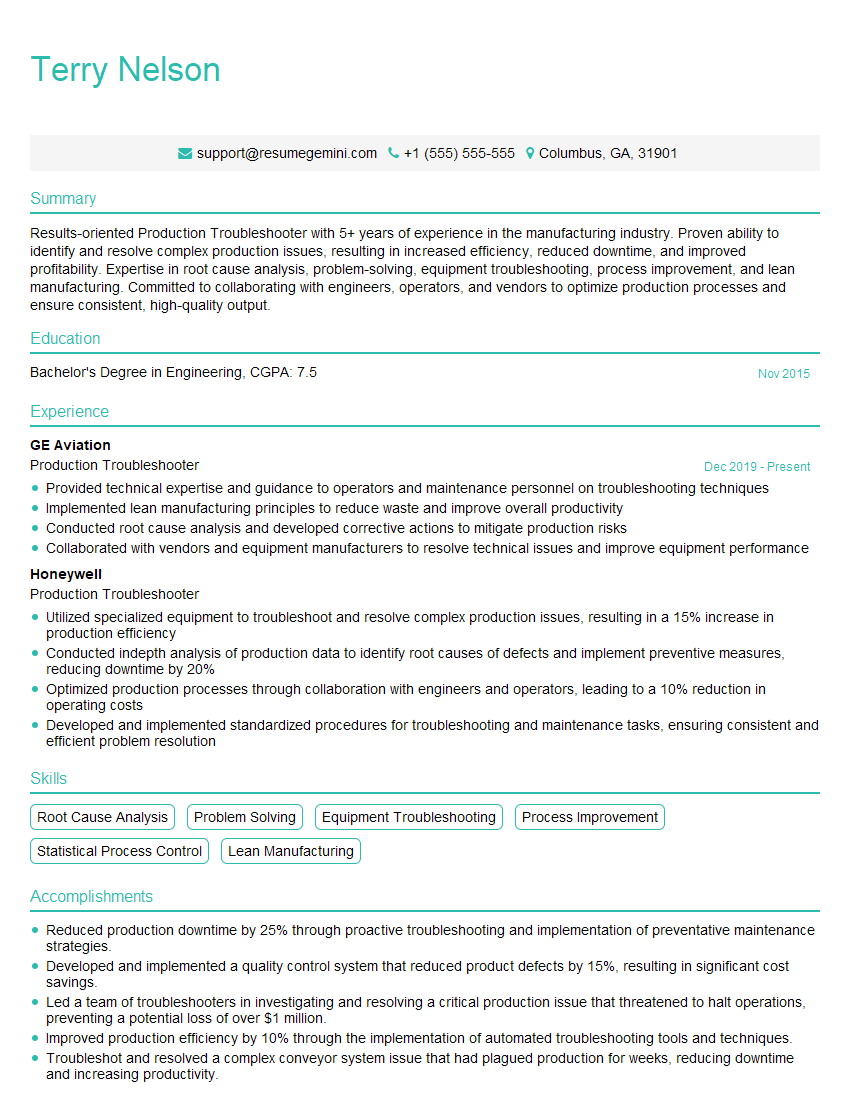

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Production Troubleshooter

1. What are your strengths and weaknesses as a Production Troubleshooter?

Strengths:

- Strong technical skills in troubleshooting and resolving production issues

- Experience in analyzing and diagnosing complex production problems

- Excellent communication and interpersonal skills

- Ability to work independently and under pressure

Weaknesses:

- Limited experience with specific industry-specific software or technologies

- Can sometimes be too detail-oriented and miss the big picture

2. What are some of the most common production issues you have encountered and how did you resolve them?

- Equipment malfunctions: Identified and repaired faulty equipment, ensuring production continuity.

- Process inefficiencies: Analyzed production processes, identified bottlenecks, and implemented solutions to improve efficiency and reduce downtime.

- Quality control issues: Conducted thorough inspections, identified product defects, and implemented corrective measures to maintain quality standards.

- Employee training gaps: Assessed employee skills, identified training needs, and provided appropriate training to enhance productivity and reduce errors.

3. What are the different types of tools and equipment you are familiar with using for troubleshooting?

- Diagnostics tools: Diagnostic software, oscilloscopes, multimeters

- Inspection equipment: Microscopes, gauges, scales

- Repair tools: Hand tools, power tools, soldering equipment

- Process monitoring tools: SCADA systems, data loggers

4. How do you stay up-to-date with the latest advancements in production technology?

- Attend industry conferences and workshops

- Read technical journals and blogs

- Engage in online forums and discussion groups

- Participate in continuing education programs

5. What are some of the challenges you have faced as a Production Troubleshooter and how did you overcome them?

- Time constraints: Prioritized tasks and worked efficiently to meet deadlines.

- Lack of resources: Collaborated with colleagues and utilized available tools to find creative solutions.

- Complex technical issues: Consulted with experts and conducted thorough research to resolve difficult problems.

- Root cause analysis: Utilized problem-solving techniques to identify and address the underlying causes of production issues.

6. What are your thoughts on the importance of preventive maintenance in production?

Preventive maintenance is crucial for:

- Reducing unplanned downtime and production interruptions

- Extending equipment lifespan and reducing maintenance costs

- Improving product quality and ensuring consistency

- Promoting employee safety by identifying potential hazards

7. What are some of the emerging trends in production troubleshooting that you are aware of?

- Remote monitoring and diagnostics: Using IoT sensors and data analytics to monitor production processes and identify issues remotely

- Predictive maintenance: Using machine learning algorithms to analyze data and predict when equipment is likely to fail

- Virtual and augmented reality: Utilizing VR/AR to provide remote assistance and enhance troubleshooting accuracy

- Cloud-based troubleshooting: Accessing diagnostic tools and data from anywhere via the cloud

8. How do you ensure that production issues are resolved permanently and do not reoccur?

- Root cause analysis: Identifying and addressing the underlying causes of issues to prevent recurrence

- Corrective action plans: Implementing specific actions to resolve issues and prevent their reappearance

- Continuous improvement: Monitoring production processes and implementing improvements to prevent future issues

- Employee training: Providing training to employees to prevent the recurrence of common errors

9. What are some of the key performance indicators (KPIs) you use to evaluate the effectiveness of your troubleshooting efforts?

- Mean time to repair (MTTR): Time taken to resolve production issues

- First-time fix rate: Percentage of issues resolved on the first attempt

- Unplanned downtime: Total amount of time lost due to unplanned disruptions

- Production efficiency: Percentage of production goals met

10. How do you work effectively with other departments, such as engineering, maintenance, and quality control, to ensure smooth production operations?

- Regular communication: Maintaining open communication channels to share information and updates

- Collaboration: Working together to identify and resolve production issues

- Shared goals: Aligning departmental goals to ensure a common focus on production efficiency

- Cross-training: Engaging in cross-training programs to develop a comprehensive understanding of different production processes

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Production Troubleshooter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Production Troubleshooter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Production Troubleshooters are responsible for identifying and resolving production issues that arise during the manufacturing process. They work closely with production teams to ensure that products are produced efficiently and to a high standard.

1. Troubleshooting Production Issues

Production Troubleshooters are responsible for identifying and resolving production issues. This may involve diagnosing the cause of the issue, developing a solution, and implementing the solution.

- Identifying and diagnosing production issues

- Developing and implementing solutions to production issues

- Working with production teams to resolve issues

2. Maintaining Production Equipment

Production Troubleshooters are also responsible for maintaining production equipment. This may involve cleaning, repairing, and calibrating equipment.

- Cleaning, repairing, and calibrating production equipment

- Performing preventive maintenance on production equipment

- Inspecting production equipment

3. Improving Production Processes

Production Troubleshooters can also be involved in improving production processes. This may involve identifying areas for improvement, developing solutions, and implementing the solutions.

- Identifying areas for improvement in production processes

- Developing and implementing solutions to improve production processes

- Working with production teams to improve production processes

4. Training Production Personnel

Production Troubleshooters may also be responsible for training production personnel. This may involve providing instruction on how to operate equipment, troubleshoot problems, and improve production processes.

- Providing instruction on how to operate production equipment

- Troubleshooting problems for production personnel

- Improving production processes for production personnel

Interview Tips

To prepare for an interview for a Production Troubleshooter position, you should:

1. Research the company and the position

Before the interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals, and it will also help you tailor your answers to the interviewer’s questions.

- Visit the company’s website

- Read the job description

- Talk to people in your network who work for the company

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself,” “Why are you interested in this position?” and “What are your strengths and weaknesses?” It is helpful to practice your answers to these questions ahead of time so that you can deliver them confidently and concisely.

- Write out your answers to common interview questions

- Practice saying your answers out loud

- Get feedback from a friend or family member

3. Be prepared to talk about your experience

The interviewer will want to know about your experience in the field. Be prepared to talk about your work history, your skills, and your accomplishments. You should also be able to provide specific examples of how you have successfully troubleshooted production issues.

- Highlight your experience in troubleshooting production issues

- Provide specific examples of your successes

- Quantify your accomplishments whenever possible

4. Be prepared to ask questions

At the end of the interview, you should be given an opportunity to ask questions. This is your chance to learn more about the company and the position, and it is also a way to show the interviewer that you are interested in the job.

- Prepare a few questions to ask the interviewer

- Ask questions that show you are interested in the job

- Avoid asking questions that are too personal

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Production Troubleshooter, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Production Troubleshooter positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.