Are you gearing up for a career in Machine Maintenance? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Machine Maintenance and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

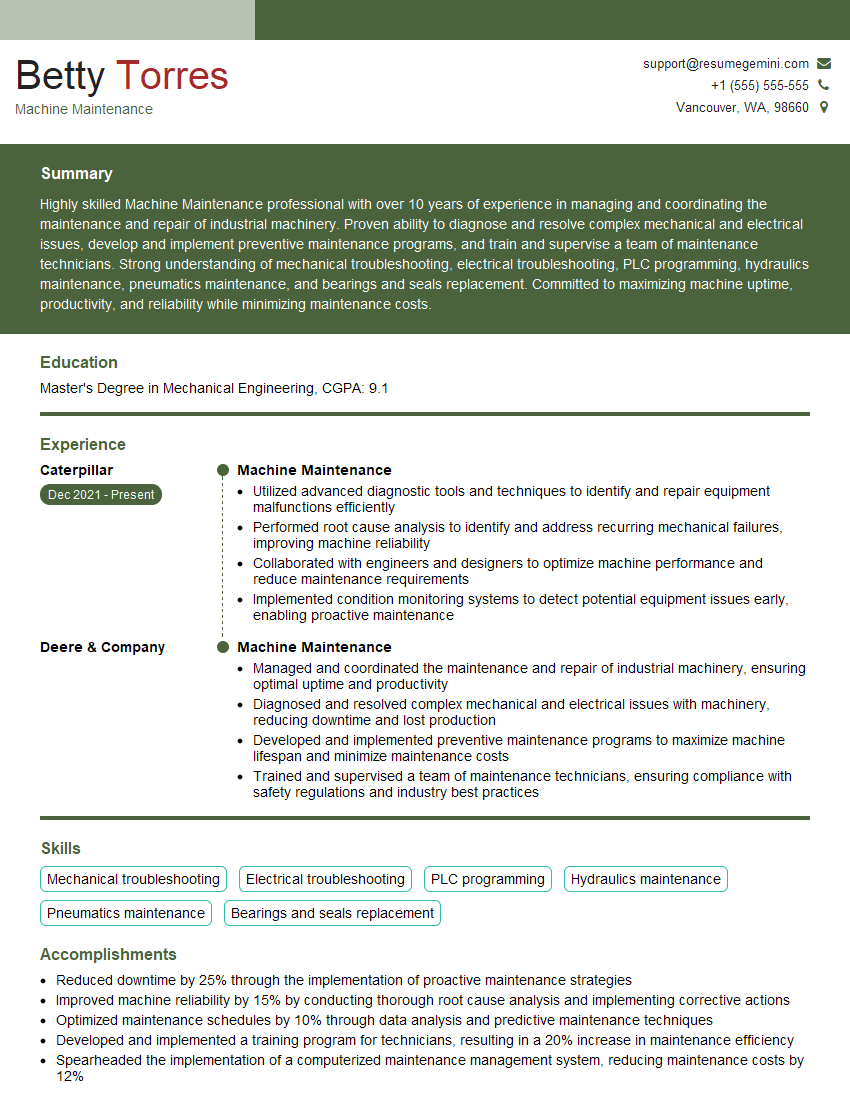

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Machine Maintenance

1. Explain the process of troubleshooting a faulty machine?

In troubleshooting a faulty machine, I employ a systematic approach:

- Gather information: Collect details about the issue, including error messages, observations, and previous maintenance history.

- Inspect the machine: Visually examine components, check connections, and verify power supply.

- Run diagnostics: Utilize built-in diagnostic tools or external software to identify potential issues.

- Isolating the problem: Divide the system into smaller units and gradually eliminate possible causes by testing and replacement.

- Repair or replace: Based on the identified issue, repair or replace faulty components with high-quality parts.

- Testing and verification: Thoroughly test the machine after the repair to ensure it functions correctly and meets specifications.

2. Describe the different types of preventive maintenance tasks you perform.

Scheduled Maintenance:

- Regular cleaning and lubrication: Ensuring moving parts operate smoothly without excessive wear.

- Filter replacement: Replacing air, oil, and hydraulic filters to maintain system cleanliness and prevent contamination.

- Belt and chain inspections: Monitoring for tension, alignment, and wear to prevent sudden failures.

Predictive Maintenance:

- Vibration analysis: Using sensors to detect imbalances, misalignments, and bearing issues before they cause breakdowns.

- Thermography: Utilizing infrared cameras to identify areas with excessive heat, indicating potential electrical or mechanical faults.

- Oil analysis: Testing oil samples to assess its condition, detect contaminants, and predict future problems.

3. How do you prioritize maintenance tasks when multiple machines require attention?

I prioritize maintenance tasks based on the following criteria:

- Criticality of the machine: Assessing the impact of downtime on production and overall operations.

- Urgency of the issue: Determining if the problem poses an immediate risk to safety or productivity.

- Availability of resources: Considering available manpower, tools, and parts to perform the maintenance efficiently.

- Cost-benefit analysis: Evaluating the potential cost savings versus the cost of maintenance to ensure optimal resource allocation.

4. What is your approach to continuous improvement in maintenance practices?

My approach to continuous improvement involves:

- Data analysis: Collecting and analyzing data on machine performance, maintenance history, and downtime to identify areas for improvement.

- Root cause analysis: Investigating the underlying causes of failures to prevent their recurrence.

- Collaboration with stakeholders: Engaging with operators, engineers, and management to gather insights and implement effective solutions.

- Benchmarking: Comparing maintenance practices with industry best practices to identify areas for improvement.

5. Describe a situation where you implemented a successful maintenance improvement initiative.

In my previous role, I implemented a preventive maintenance program that significantly reduced machine downtime. By analyzing historical data, identifying common failure points, and implementing scheduled maintenance tasks, we:

- Reduced unplanned downtime by 30%.

- Extended the lifespan of critical components.

- Improved production efficiency and overall equipment effectiveness.

6. How do you stay updated on the latest advancements in maintenance technology?

I stay updated through:

- Industry publications and conferences: Subscribing to journals, attending seminars, and participating in professional organizations.

- Online courses and webinars: Enrolling in training programs and attending live or recorded webinars offered by equipment manufacturers and technology providers.

- Collaboration with vendors: Building relationships with vendors to gain access to technical updates, product advancements, and industry best practices.

7. What are the safety protocols you follow when performing maintenance?

I strictly adhere to the following safety protocols:

- Lockout/tagout procedures: Isolating and de-energizing equipment before performing maintenance to prevent unexpected startup.

- Personal protective equipment: Wearing appropriate safety gear such as gloves, safety glasses, and protective clothing.

- Hazard assessment: Identifying potential hazards and developing mitigation plans before starting work.

- Proper tool selection and usage: Utilizing the right tools for the job and following safe operating procedures.

- Working in teams: Maintaining clear communication and working with a partner when necessary for safety-critical tasks.

8. How do you manage spare parts inventory?

I manage spare parts inventory using a combination of techniques:

- Criticality analysis: Identifying and maintaining an adequate stock of critical spare parts essential for minimizing downtime.

- Inventory control system: Utilizing inventory management software or spreadsheets to track stock levels, reorder points, and lead times.

- Supplier relationships: Establishing partnerships with reliable suppliers to ensure timely delivery of parts when needed.

- Kanban or just-in-time inventory: Implementing visual cues or electronic systems to trigger reorders when stock reaches a certain level.

- Regular inventory audits: Conducting periodic audits to verify stock levels, accuracy, and optimal storage conditions.

9. Describe your experience in working with computerized maintenance management systems (CMMS).

I have extensive experience in working with CMMS, specifically [CMMS name]. I utilize CMMS to:

- Work order management: Creating, assigning, and tracking work orders for maintenance tasks.

- Equipment history tracking: Maintaining a comprehensive record of maintenance history, including inspections, repairs, and replacements.

- Inventory management: Tracking spare parts inventory, reordering levels, and managing vendor relationships.

- Planned maintenance scheduling: Utilizing the CMMS to schedule and optimize preventive maintenance tasks.

- Reporting and analysis: Generating reports and analyzing data on machine performance, maintenance costs, and downtime.

10. How do you handle working under pressure and meeting tight deadlines?

I thrive under pressure and am adept at managing my time effectively to meet tight deadlines. I approach these situations with:

- Prioritization: Identifying the most critical tasks and prioritizing them to ensure they are completed on time.

- Time management: Utilizing tools and techniques such as to-do lists, calendar planning, and time blocking to allocate my time wisely.

- Communication: Maintaining open communication with stakeholders to keep them informed of progress and any potential challenges.

- Delegation: When feasible, delegating tasks to capable team members to distribute the workload and meet deadlines.

- Staying calm and focused: Maintaining a positive and focused mindset, avoiding distractions, and focusing on completing the task at hand.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Machine Maintenance.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Machine Maintenance‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Machine Maintenance professionals play a crucial role in ensuring the smooth operation of industrial machinery. Their responsibilities encompass a wide range of tasks aimed at maintaining, troubleshooting, and repairing machinery to optimize productivity and prevent downtime.

1. Inspect and Diagnose Machinery

Regularly inspect machinery to identify potential problems or areas for improvement. Conduct thorough diagnostic assessments to determine the root causes of malfunctions or irregularities.

- Use specialized tools and equipment for inspections and diagnostics

- Troubleshoot complex technical issues and identify solutions

2. Perform Maintenance and Repairs

Conduct routine and scheduled preventive maintenance tasks to keep machinery in optimal condition. Execute repairs as necessary, ensuring timely and effective restoration of functionality.

- Replace worn or damaged parts

- Lubricate and adjust machinery components

3. Monitor Equipment Performance

Monitor equipment performance through data analysis, sensor readings, and visual observations. Identify trends and patterns that may indicate potential issues or areas for improvement.

- Use predictive maintenance techniques to forecast potential failures

- Communicate performance data to relevant stakeholders

4. Maintain Maintenance Records

Maintain accurate and up-to-date maintenance records, including inspection reports, repair logs, and inventory of spare parts. Ensure compliance with regulatory requirements and industry best practices.

- Organize and manage maintenance documentation

- Collaborate with management and other departments on maintenance-related matters

Interview Tips

Preparing for a Machine Maintenance interview requires thorough research and understanding of the role and industry. Here are some tips to help candidates ace the interview:

1. Research the Company and Position

Research the company’s history, products, and industry standing. Familiarize yourself with the specific requirements and responsibilities of the Machine Maintenance position you are applying for.

- Visit the company website and social media pages

- Read industry publications and news articles

2. Highlight Relevant Experience and Skills

Tailor your resume and interview responses to emphasize your relevant experience in machine maintenance. Showcase your technical skills, problem-solving abilities, and knowledge of maintenance best practices.

- Quantify your accomplishments with specific examples

- Use keywords and industry-specific terminology that match the job description

3. Prepare for Technical Questions

Expect questions related to your technical expertise, troubleshooting skills, and knowledge of specific equipment. Practice answering questions about common maintenance procedures, diagnostic techniques, and safety protocols.

- Review your notes on maintenance methodologies and specific equipment

- Prepare examples of how you have resolved complex technical issues in the past

4. Demonstrate Enthusiasm and Professionalism

Show enthusiasm for the role of Machine Maintenance and express your passion for keeping machinery running smoothly. Maintain a professional demeanor throughout the interview, dress appropriately, and arrive on time.

- Ask insightful questions to show your engagement

- Be respectful of the interviewer’s time and follow-up promptly

5. Practice Job Scenario Questions

Interviewers may ask job scenario questions to assess your problem-solving skills and decision-making abilities. Prepare for questions that require you to troubleshoot a malfunctioning machine or implement a new maintenance strategy.

- Think through the steps you would take to address the scenario

- Explain your thought process and prioritize your actions

Next Step:

Now that you’re armed with the knowledge of Machine Maintenance interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Machine Maintenance positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini