Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Oxyacetylene Burner position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

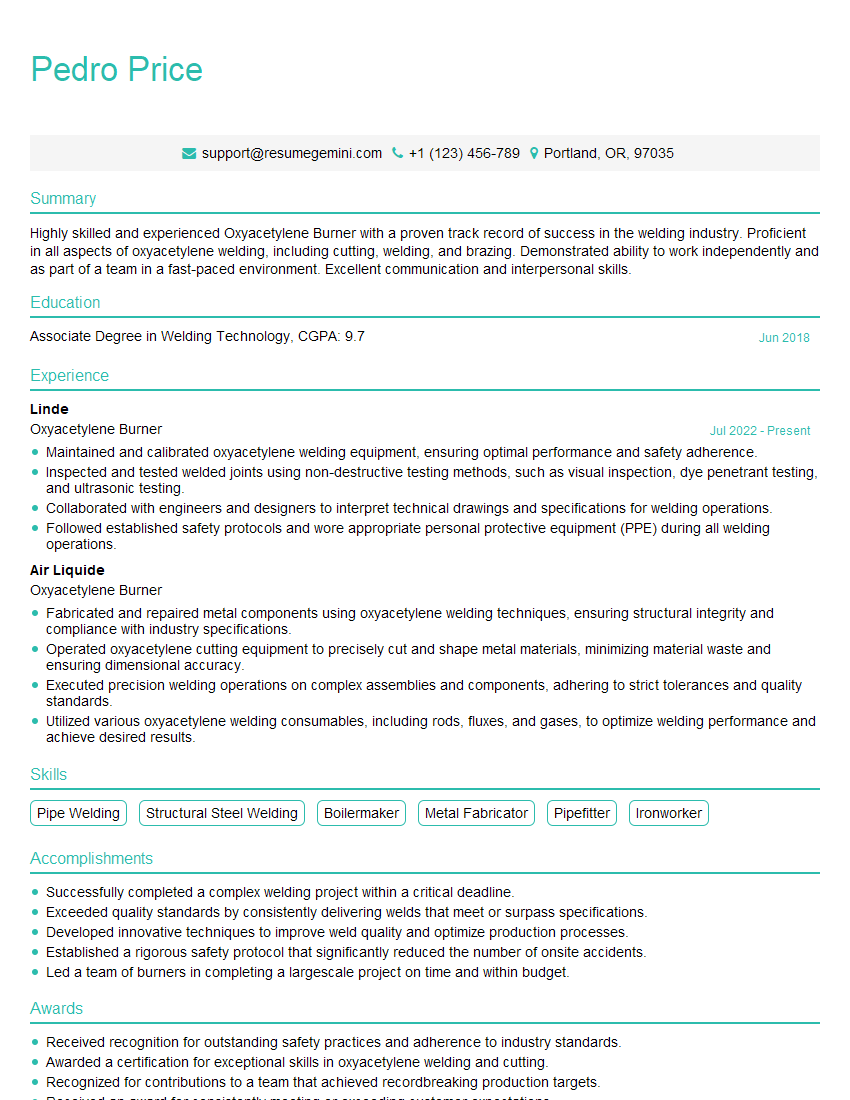

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Oxyacetylene Burner

1. What are the key safety precautions that must be taken when operating an oxyacetylene burner?

- Ensure that the work area is well-ventilated and free of flammable materials.

- Wear appropriate protective clothing, including gloves, eye protection, and fire-resistant clothing.

- Inspect the equipment regularly for leaks or damage and never operate a faulty burner.

- Store oxygen and acetylene cylinders securely and separately, in an upright position and secured with chains.

- Never smoke or work near open flames when handling oxyacetylene equipment.

2. What are the different types of flames produced by an oxyacetylene burner?

- Neutral flame: Blue inner cone with a slightly oxidizing outer cone, used for welding.

- Oxidizing flame: Shorter, bluer inner cone with a larger, more defined outer cone, used for cutting metal.

- Reducing (or carburizing) flame: Longer, brighter inner cone with a smaller outer cone, used for heating metal or brazing.

3. How do you adjust the flame of an oxyacetylene burner?

- Adjust the oxygen flow rate to control the inner cone length: shorter for neutral flame, longer for oxidizing flame.

- Adjust the acetylene flow rate to control the outer cone shape: smaller for oxidizing flame, larger for reducing flame.

4. What are the different welding techniques used with an oxyacetylene burner?

- Left-hand welding: Torch in left hand, filler rod in right, used for welding thin materials.

- Right-hand welding: Torch in right hand, filler rod in left, used for welding thicker materials.

- Forehand welding: Flame directed ahead of the weld pool, used for most general welding.

- Backhand welding: Flame directed behind the weld pool, used for welding thicker materials or when visibility is limited.

5. What are the different types of tips used on oxyacetylene burners?

Tips vary in size and shape depending on the desired flame size and shape, material being welded, and thickness of the metal.

6. What factors affect the quality of an oxyacetylene weld?

- Proper flame adjustment

- Correct welding technique

- Cleanliness of the metal surfaces

- Appropriate filler rod selection

7. How do you maintain an oxyacetylene burner?

- Clean the tip regularly to prevent clogging.

- Check and replace worn or damaged hoses and fittings.

- Lubricate moving parts as recommended by the manufacturer.

8. What is the difference between oxyacetylene welding and oxyacetylene cutting?

- Welding: Uses a neutral or reducing flame to join metal pieces by melting and fusing them together.

- Cutting: Uses an oxidizing flame to cut through metal by rapidly oxidizing and melting the metal.

9. Describe the process of cutting metal with an oxyacetylene burner.

- Set the burner to an oxidizing flame.

- Hold the torch at a 90-degree angle to the metal.

- Start the cut by preheating the metal along the desired cut line.

- Once the metal is hot enough, move the torch along the cut line, directing the flame slightly ahead of the cut.

10. What are the advantages and disadvantages of using an oxyacetylene burner?

Advantages

- Versatile tool for welding, cutting, and heating metal.

- Produces a hot, concentrated flame for precise work.

- Relatively low equipment cost.

Disadvantages

- Requires careful handling and safety precautions due to flammable gases.

- Produces fumes that require proper ventilation.

- Limited penetration depth compared to other welding methods.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Oxyacetylene Burner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Oxyacetylene Burner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Oxyacetylene Burner is a skilled professional who uses oxyacetylene torches to cut, weld, and heat metal in various construction and industrial settings. Their responsibilities include:

1. Cutting, Welding, and Brazing

Using oxyacetylene torches to cut metal into desired shapes, join metal pieces by welding, and braze metal parts together

- Operate oxyacetylene torches to produce high temperatures for cutting, welding, and brazing

- Set up equipment and adjust flame characteristics to achieve precise results

2. Surface Preparation

Preparing metal surfaces for welding or cutting by removing rust, dirt, and other contaminants

- Clean and grind metal surfaces to ensure proper adhesion and weld strength

- Use appropriate tools and chemicals for surface preparation

3. Equipment Maintenance

Maintaining and troubleshooting oxyacetylene equipment to ensure optimal performance

- Inspect and clean torches, hoses, and regulators regularly

- Identify and resolve equipment malfunctions or leaks

4. Safety Compliance

Following safety protocols and regulations related to oxyacetylene operations

- Wear appropriate personal protective equipment (PPE) and follow industry safety guidelines

- Store and handle oxyacetylene gases safely

Interview Tips

To ace your interview for an Oxyacetylene Burner position, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s background, industry, and specific projects they undertake. Research the job description thoroughly to understand the key responsibilities and required skills

- Visit the company’s website and social media pages

- Read industry publications and articles

2. Highlight Relevant Experience and Skills

Emphasize your experience in oxyacetylene cutting, welding, and brazing. Quantify your accomplishments and provide specific examples of your work. Showcase your ability to work independently and as part of a team

- Provide details of your previous projects, including the materials and techniques used

- Discuss your experience with different types of oxyacetylene equipment

3. Demonstrate Safety Knowledge

Employers prioritize safety in oxyacetylene operations. Demonstrate your understanding of safety protocols, PPE, and proper handling of gases. Highlight your commitment to adhering to safety regulations

- Discuss your training and certifications related to oxyacetylene safety

- Provide examples of your safety practices in previous work environments

4. Practice Common Interview Questions

Prepare for common interview questions related to oxyacetylene burning, such as:

- Describe your experience with oxyacetylene cutting, welding, and brazing.

- How do you ensure the quality of your work?

- What safety measures do you take when working with oxyacetylene gases?

5. Ask Thoughtful Questions

At the end of the interview, ask insightful questions that show your interest in the position and the company. This demonstrates your preparation and eagerness to learn more

- Inquire about the company’s future projects

- Ask about opportunities for professional development

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Oxyacetylene Burner interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!