Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Pressure Tank Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

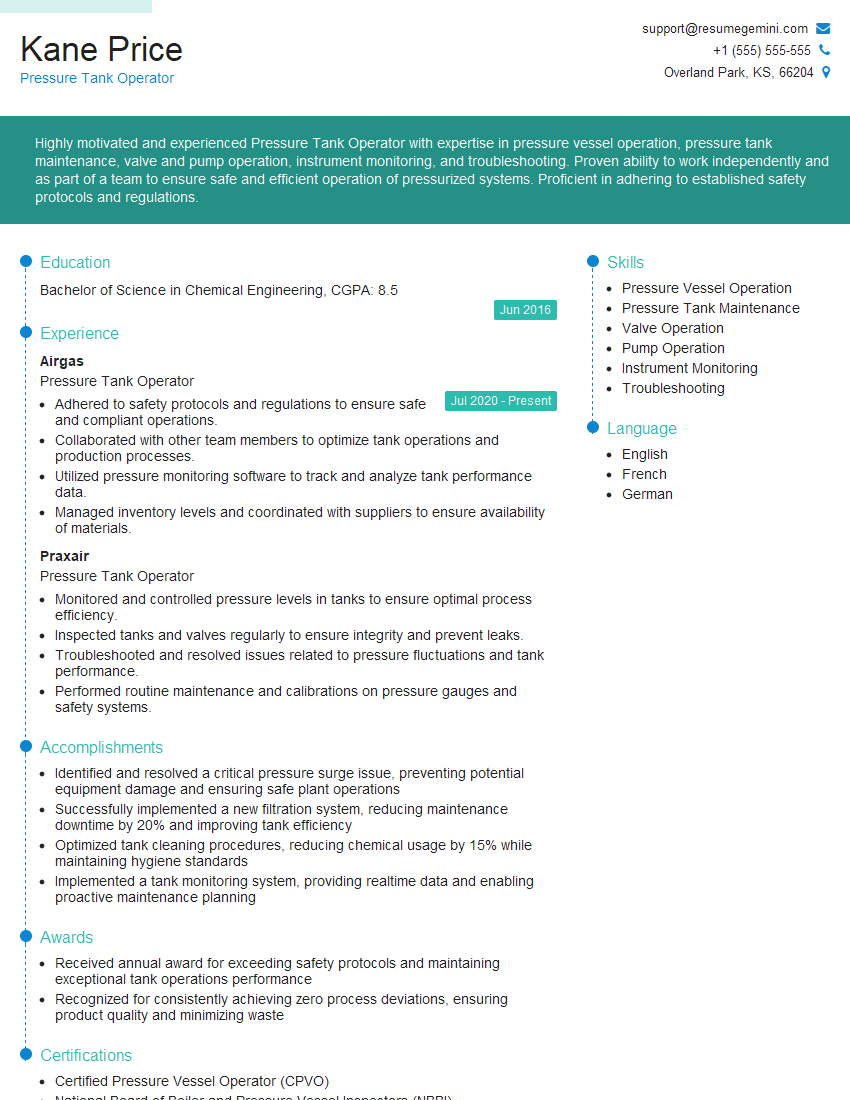

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Pressure Tank Operator

1. Explain the role and responsibilities of a Pressure Tank Operator.

As a Pressure Tank Operator, my primary responsibilities include:

- Monitoring and maintaining pressure levels in pressure tanks

- Inspecting tanks for leaks, corrosion, and other defects

- Operating and maintaining valves, pumps, and other equipment

- Following safety protocols and procedures

- Recording and reporting data on pressure tank operations

2. What are the key safety considerations when working with pressure tanks?

Understanding Pressure Limits

- Adhering to maximum pressure ratings for tanks and components

- Using pressure relief devices to prevent over-pressurization

Hazard Identification

- Recognizing potential hazards such as leaks, ruptures, or explosions

- Implementing appropriate safety measures to mitigate risks

Emergency Response

- Knowing emergency procedures in case of leaks, fires, or other incidents

- Wearing proper protective gear and following evacuation protocols

3. Describe the steps involved in inspecting pressure tanks for defects.

- Visual inspection for cracks, corrosion, or damage

- Hydrostatic testing to check for leaks and structural integrity

- Ultrasonic testing to detect internal defects

- Magnetic particle testing to identify surface defects

- Documenting inspection findings and taking corrective actions

4. How do you troubleshoot common problems with pressure tanks, such as leaks or pressure fluctuations?

- Identifying the source of the leak (e.g., gasket, valve, or tank body)

- Tightening or replacing faulty components

- Adjusting pressure settings or replacing defective regulators

- Monitoring pressure readings and making necessary adjustments

- Referencing technical manuals or seeking guidance from experienced colleagues

5. What are the different types of pressure tanks and their applications?

- Storage tanks: Holding gases or liquids under pressure for later use

- Process tanks: Used in industrial processes, such as chemical reactions or heat transfer

- Transport tanks: Designed for transporting gases or liquids over long distances

- Hydro-pneumatic tanks: Combining water and compressed air for water supply or storage

- Diaphragm tanks: Separating air or gas from liquids using a flexible diaphragm

6. How do you ensure compliance with industry standards and regulations related to pressure tank operations?

- Following established codes and standards (e.g., ASME, API)

- Maintaining proper documentation and records

- Participating in training and certification programs

- Undergoing regular inspections and audits

- Seeking guidance from regulatory agencies or industry experts

7. Describe your experience in using specialized equipment or tools for pressure tank operations.

In my previous role, I was responsible for operating and maintaining a variety of specialized equipment, including:

- Pressure gauges and transmitters

- Flow meters and regulators

- Safety relief valves and bursting discs

- Hydrostatic testing equipment

- Ultrasonic testing equipment

I have also received training and certification in the use of these tools and equipment.

8. How do you stay up-to-date on the latest industry best practices and technological advancements in pressure tank operations?

- Attending industry conferences and seminars

- Reading technical journals and articles

- Consulting with experts and peers

- Participating in online forums and discussion groups

- Taking advantage of manufacturer training and certification programs

9. What is your approach to ensuring the safety and efficiency of pressure tank operations?

My approach to ensuring safety and efficiency involves:

- Adhering to established safety protocols and procedures

- Conducting regular inspections and preventive maintenance

- Using appropriate personal protective equipment (PPE)

- Following proper operating procedures

- Monitoring pressure levels and making necessary adjustments

- Responding promptly to any abnormal conditions or emergencies

10. Can you share an example of a challenging situation you faced as a Pressure Tank Operator and how you resolved it?

In my previous role, we experienced a sudden pressure drop in one of the storage tanks. I followed the emergency procedures, isolated the tank, and conducted a thorough inspection. I identified a leaking valve as the source of the problem. I promptly replaced the valve, restored pressure, and resumed normal operations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Pressure Tank Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Pressure Tank Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Pressure Tank Operators are responsible for managing and maintaining pressurized tanks and related equipment. They also monitor pressure levels, maintain safety records, and ensure that all systems are functioning correctly.

1. Operate Pressure Tank System

Operate and monitor pressure tanks, pumps, valves, and associated equipment to maintain desired pressure levels and flows.

- Start, stop, and adjust equipment to meet process requirements.

- Monitor pressure gauges, flow meters, and other instruments to ensure proper operation.

2. Maintain and Repair Equipment

Perform routine maintenance and repairs on pressure tanks, pumps, and other equipment. Troubleshoot and resolve mechanical and electrical issues.

- Inspect and clean equipment regularly.

- Replace worn or damaged parts.

- Calibrate and adjust instruments.

3. Safety and Compliance

Ensure compliance with safety regulations and procedures. Conduct safety inspections and maintain proper documentation.

- Wear appropriate safety gear.

- Follow lockout/tagout procedures.

- Maintain Material Safety Data Sheets (MSDSs).

4. Quality Control and Documentation

Monitor product quality and maintain accurate records of operations. Conduct tests and inspections to ensure adherence to specifications.

- Take samples and perform quality checks.

- Prepare and maintain logs and reports.

- Identify and address deviations from standards.

Interview Preparation Tips

To prepare for a Pressure Tank Operator interview, it’s crucial to:

1. Research the Company and Position

Gather information about the company’s industry, size, and culture. Understand the specific responsibilities of the Pressure Tank Operator role within the organization.

- Visit the company website.

- Read industry news and reports.

- Connect with current or former employees on LinkedIn.

2. Practice Common Interview Questions

Prepare answers to common interview questions related to your experience, skills, and qualifications. Consider using the STAR method (Situation, Task, Action, Result) to provide concise and impactful responses.

- Tell me about your experience with pressure tank systems.

- Describe a time when you had to troubleshoot and repair a mechanical issue.

- How do you ensure compliance with safety regulations?

3. Highlight Your Technical Skills

Emphasize your technical proficiency in operating, maintaining, and repairing pressure tank systems. Mention specific tools, equipment, and software you have experience with.

- List your experience with different types of pressure tanks.

- Describe your knowledge of pressure control valves and piping systems.

- Mention any certifications or licenses you hold.

4. Demonstrate Your Safety Awareness

Showcase your understanding of safety protocols and procedures in a hazardous environment. Highlight your experience with risk assessment, emergency response, and personal protective equipment.

- Explain your knowledge of lockout/tagout procedures.

- Describe your experience with handling hazardous materials.

- Share examples of how you have implemented safety measures in the workplace.

5. Prepare Questions for the Interviewers

Asking thoughtful questions shows that you are engaged and interested in the position. Prepare questions about the company’s growth plans, the role’s responsibilities within the team, and opportunities for professional development.

- What are the company’s goals for the next year?

- How does the Pressure Tank Operator role contribute to the team’s success?

- What opportunities are there for training and advancement?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Pressure Tank Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.