Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Lacquer Maker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Lacquer Maker so you can tailor your answers to impress potential employers.

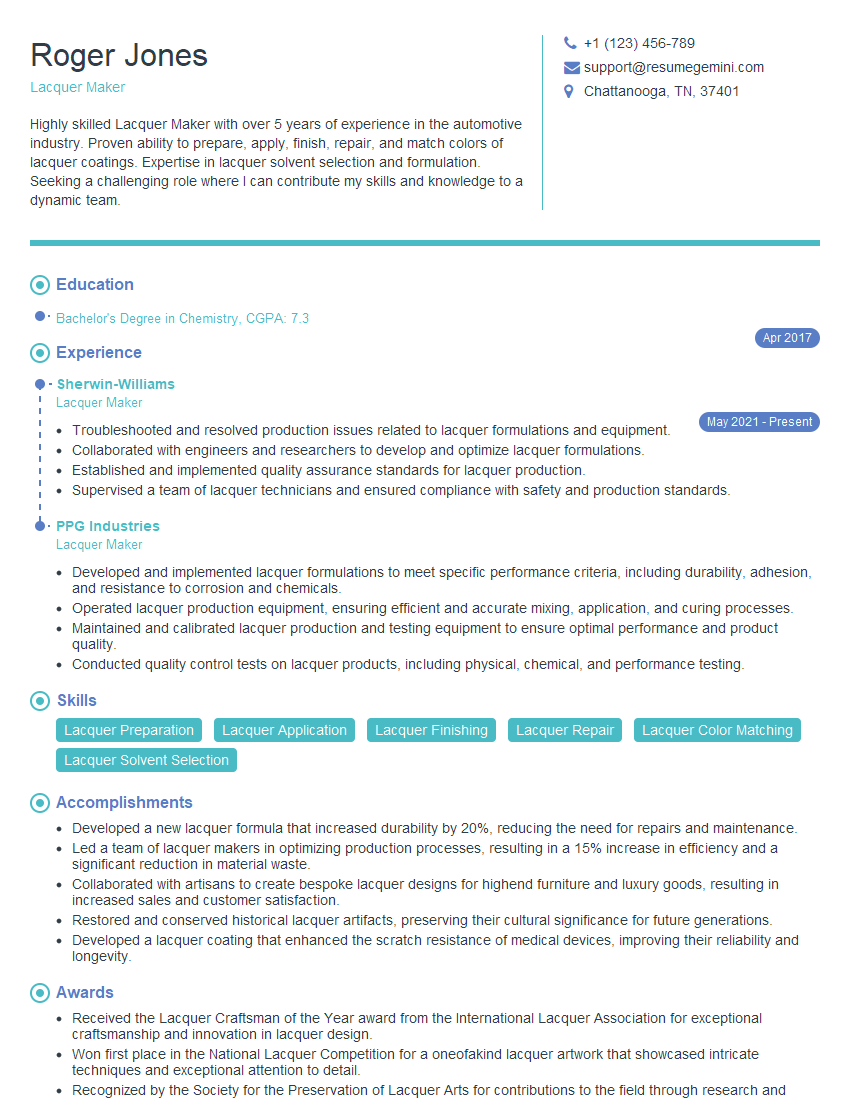

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Lacquer Maker

1. What are the different types of lacquers, and what are their specific properties?

There are three main types of lacquers: natural, synthetic, and water-based. Natural lacquers are made from the sap of the lacquer tree, and they are known for their durability and high gloss. Synthetic lacquers are made from petroleum-based materials, and they are less durable than natural lacquers but more resistant to chemicals. Water-based lacquers are made from acrylic resins, and they are the most environmentally friendly type of lacquer.

2. What are the different methods of applying lacquer, and what are the pros and cons of each method?

Spraying

- Pros: Fast and efficient, even application, can reach hard-to-reach areas.

- Cons: Requires specialized equipment, can produce overspray, can be difficult to control.

Brushing

- Pros: Simple and straightforward, relatively inexpensive, provides more control over application.

- Cons: Time-consuming, can leave brush marks, can be difficult to achieve an even finish.

Dipping

- Pros: Fast and efficient, produces a consistent finish, no overspray.

- Cons: Requires specialized equipment, can be difficult to control thickness, can be difficult to achieve a uniform finish on complex shapes.

3. What are the different factors that can affect the quality of a lacquer finish, and how can these factors be controlled?

- Surface preparation: The surface must be clean, dry, and free of any contaminants.

- Lacquer quality: The quality of the lacquer will directly affect the quality of the finish.

- Application method: The application method must be appropriate for the lacquer and the desired finish.

- Environmental conditions: The temperature and humidity must be controlled during application and curing.

4. What are the different techniques that can be used to repair or refinish a lacquer finish?

- Touch-up: Small scratches or chips can be repaired with touch-up lacquer.

- Refinishing: The entire finish can be refinished by removing the old lacquer and applying a new finish.

5. What are the different safety precautions that must be taken when working with lacquer?

- Wear appropriate protective gear, including gloves, eye protection, and a respirator.

- Work in a well-ventilated area.

- Store lacquer in a cool, dry place away from heat and ignition sources.

6. What are the different types of equipment that are used in lacquer making, and what are their functions?

- Lacquer tree: The lacquer tree is the source of the sap that is used to make natural lacquer.

- Lacquerware: Lacquerware is a type of art that uses lacquer to decorate objects.

- Lacquer brushes: Lacquer brushes are used to apply lacquer to surfaces.

- Spray guns: Spray guns are used to spray lacquer onto surfaces.

- Mixers: Mixers are used to mix lacquer with other ingredients.

7. What are the different types of finishes that can be achieved with lacquer, and how can these finishes be customized?

- Gloss: Gloss finishes are shiny and reflective.

- Semi-gloss: Semi-gloss finishes have a moderate amount of shine.

- Matte: Matte finishes are dull and non-reflective.

- Color: Lacquer can be tinted to achieve a variety of colors.

- Texture: Lacquer can be applied over different textures to create different effects.

- Aging: Lacquer can be aged to give it a vintage look.

8. What are the different trends in lacquer making, and how can these trends be incorporated into your work?

- Sustainable lacquer making: Using environmentally friendly materials and processes.

- Custom lacquer finishes: Creating unique and personalized finishes.

- Lacquer art: Using lacquer to create works of art.

9. What are the different challenges that you have faced in your work as a lacquer maker, and how have you overcome these challenges?

- Achieving the desired finish: It takes practice and experience to achieve the desired finish.

- Working with different materials: Lacquer can be used on a variety of materials, and it is important to know how to work with each material.

- Meeting deadlines: Lacquer making can be time-consuming, and it is important to be able to meet deadlines.

10. What are your goals for your career as a lacquer maker, and how do you plan to achieve these goals?

- Become a master lacquer maker: I want to learn all the different techniques of lacquer making and become a master of the craft.

- Develop my own unique style: I want to develop my own unique style of lacquer making that is both beautiful and functional.

- Teach lacquer making: I want to teach lacquer making to others and share my knowledge of the craft.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Lacquer Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Lacquer Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Lacquer Makers are responsible for the production of lacquers, which are used as coatings for various surfaces such as furniture, musical instruments, and artwork.

1. Formulation and Mixing

Lacquer Makers develop and mix lacquer formulations according to specific requirements, ensuring the desired color, texture, and durability.

- Determine the appropriate lacquer base, solvents, and additives based on the desired properties.

- Weigh, measure, and mix components precisely to create the lacquer formulation.

2. Application and Finishing

Lacquer Makers apply the lacquer to surfaces using techniques such as spraying, brushing, or dipping.

- Prepare surfaces by cleaning, sanding, or priming to ensure proper adhesion.

- Apply lacquer evenly and smoothly using the appropriate application method.

- Monitor drying and curing processes to achieve the desired finish.

3. Quality Control

Lacquer Makers inspect and test the finished lacquer to ensure it meets quality standards.

- Perform visual inspections for defects such as bubbles, cracks, or discoloration.

- Conduct hardness, adhesion, and durability tests to assess the performance of the lacquer.

4. Maintenance and Housekeeping

Lacquer Makers maintain equipment and ensure a clean and organized work environment.

- Clean and maintain spray guns, brushes, and other equipment.

- Dispose of lacquer waste and hazardous materials in accordance with environmental regulations.

Interview Tips

Preparing for a Lacquer Maker interview can significantly increase your chances of success.

1. Research the Company and Position

Familiarize yourself with the company’s history, products, and values. Understanding the specific requirements of the Lacquer Maker position will help you tailor your answers to the interviewer’s questions.

2. Practice Your Responses

Anticipate common interview questions and prepare thoughtful, concise answers. Practice delivering your responses clearly and confidently.

3. Showcase Your Technical Skills

Highlight your knowledge of lacquer formulations, application techniques, and quality control procedures. Provide specific examples of projects or experiences that demonstrate your technical proficiency.

4. Emphasize Attention to Detail

Lacquer Making requires meticulous attention to detail. Emphasize your ability to follow instructions precisely, inspect products thoroughly, and maintain a clean work environment.

5. Highlight Your Safety Awareness

Working with lacquers involves handling hazardous materials. Stress your understanding of safety protocols, proper disposal techniques, and the use of personal protective equipment.

6. Ask Informed Questions

Asking thoughtful questions during the interview demonstrates your interest and engagement. Prepare questions about the company’s lacquer production processes, challenges, and opportunities for professional development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Lacquer Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!