Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Barratte Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

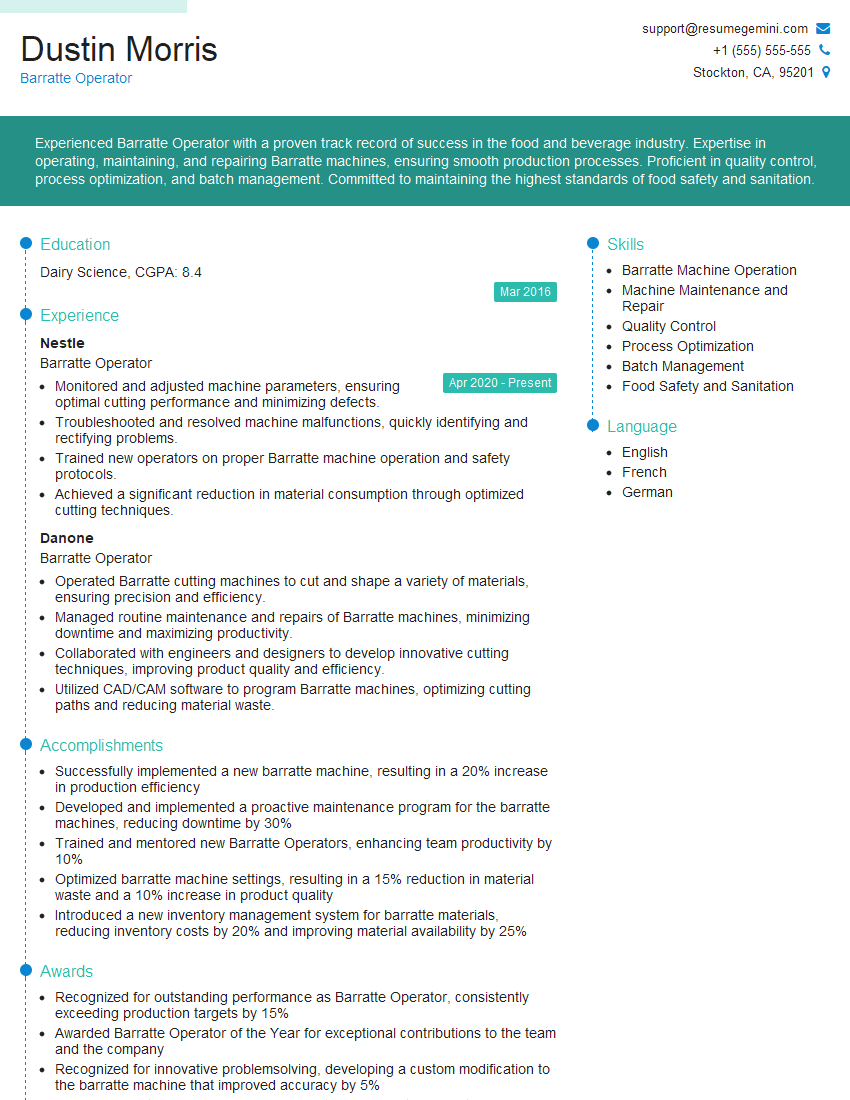

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Barratte Operator

1. What are the key responsibilities of a Barratte Operator?

As a Barratte Operator, my primary responsibilities involve operating and monitoring the Barratte machine during the cheesemaking process. My tasks include:

- Loading milk into the Barratte machine and ensuring proper temperature control

- Adding starter cultures and rennet to initiate coagulation

- Monitoring the curd formation and cutting the curd at the optimal time

- Separating the whey from the curds

- Controlling the curd agitation and salting to develop the desired texture and flavor

- Unloading the finished cheese from the machine

2. Describe the different types of cheeses produced using a Barratte machine.

- Cheddar: A hard, yellow cheese with a sharp, tangy flavor

- Mozzarella: A soft, white cheese with a mild, slightly salty flavor

- Parmesan: A hard, grating cheese with a nutty, fruity flavor

- Gouda: A semi-hard, yellow cheese with a buttery, caramel-like flavor

- Feta: A soft, white cheese with a tangy, salty flavor

3. Explain the process of curd cutting and its significance in cheesemaking.

Curd cutting is a crucial step in the cheesemaking process as it determines the size, texture, and moisture content of the final cheese. I use a special knife or wire to cut the curd into small, uniform cubes.

The size of the curd pieces affects the rate of whey drainage and the moisture content of the cheese. Smaller curd pieces result in a faster drainage and a drier cheese, while larger curd pieces produce a slower drainage and a moister cheese.

4. How do you control the moisture content of cheese?

Controlling moisture content is essential for the texture, flavor, and shelf life of the cheese. I regulate moisture by:

- Curd cutting: Smaller curd pieces increase surface area, promoting whey drainage

- Stirring: Gentle stirring allows whey to release from the curd

- Matting: Pressing the curd into blocks encourages whey expulsion

- Acidification: Lower pH levels cause the curd to contract, releasing whey

5. What are the common problems encountered during Barratte operation and how do you troubleshoot them?

- Curd formation issues: I adjust the temperature, rennet amount, or starter cultures to correct coagulation problems.

- Whey separation difficulties: I modify the cutting time, stirring speed, or temperature to facilitate whey drainage.

- Block formation challenges: I adjust the pressing pressure, matting time, or curd firmness to improve block formation.

- Equipment malfunctions: I follow maintenance protocols, troubleshoot mechanical issues, and contact a technician if necessary.

6. How do you maintain the hygiene and sanitation of the Barratte machine and production area?

Maintaining hygiene is paramount in cheesemaking. I strictly follow the following practices:

- Regular cleaning and sanitizing of all equipment and surfaces

- Personal hygiene, including wearing appropriate protective gear

- Monitoring and controlling temperature to prevent bacterial growth

- Implementing HACCP (Hazard Analysis and Critical Control Points) principles

7. What is the role of starter cultures in cheesemaking?

Starter cultures are essential microorganisms that convert lactose in milk into lactic acid. This acidification process lowers the pH of the milk, leading to coagulation and the formation of curd.

- Different starter cultures produce different flavors and textures in cheese

- I carefully select and manage starter cultures based on the desired cheese characteristics

8. Explain the importance of precise temperature control in cheesemaking.

Temperature plays a critical role in cheesemaking by influencing:

- Starter culture activity: Optimal temperature ranges ensure proper acid development

- Coagulation rate: Temperature affects the rate and efficiency of curd formation

- Curd texture: Temperature impacts the firmness and moisture content of the curd

- Cheese ripening: Temperature influences the rate and characteristics of cheese aging

9. Describe the different stages of cheese ripening and their impact on flavor and texture.

Cheese ripening is a controlled aging process that develops flavor, texture, and appearance.

- Acid development: Lactic acid bacteria convert lactose to lactic acid, lowering pH and creating a sour flavor

- Proteolysis: Enzymes break down proteins into peptides and amino acids, enhancing flavor and texture

- Lipolysis: Enzymes release fatty acids from fats, contributing to flavor and aroma

- Mold growth: Specific molds (e.g., Penicillium roqueforti) introduce unique flavors and textures (e.g., blue cheese)

10. How do you ensure the quality and consistency of cheese produced using a Barratte machine?

I implement the following quality control measures:

- Raw material inspection: I check the quality of milk, starter cultures, and other ingredients

- Process monitoring: I continuously monitor temperature, pH, and other parameters throughout production

- Sensory evaluation: I conduct regular taste tests to evaluate flavor, texture, and appearance

- Recordkeeping: I maintain records of all production parameters and quality control results

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Barratte Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Barratte Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Barratte Operators are responsible for operating and maintaining barratte machines, which are used to produce a variety of paper products. They must be able to work independently and follow detailed instructions to ensure the proper and safe operation of the machine.

1. Operating the barratte machine

The Barratte Operator is responsible for the safe and efficient operation of the barratte machine. They must be able to start, stop, and adjust the machine as needed to produce the desired product.

- Monitoring the machine’s operation

- Adjusting the machine’s settings

- Troubleshooting and repairing minor machine problems

2. Maintaining the barratte machine

The Barratte Operator is also responsible for maintaining the barratte machine. They must be able to perform routine maintenance tasks, such as cleaning, lubricating, and inspecting the machine. They must also be able to identify and repair minor problems with the machine.

- Cleaning the machine

- Lubricating the machine

- Inspecting the machine

- Repairing minor problems

3. Quality control

The Barratte Operator is responsible for the quality of the products produced by the barratte machine. They must be able to inspect the products for defects and ensure that they meet the required standards.

- Inspecting the products

- Identifying defects

- Rejecting defective products

4. Safety

The Barratte Operator must be aware of the safety hazards associated with operating a barratte machine. They must be able to follow safety procedures and use proper safety equipment to prevent accidents.

- Following safety procedures

- Using proper safety equipment

- Reporting safety hazards

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to increase your chances of success. Here are a few tips to help you ace your interview for a Barratte Operator position:

1. Research the company and the position

The first step to preparing for an interview is to research the company and the position you’re applying for. This will give you a better understanding of the company’s culture, the expectations for the position, and the skills and experience that the interviewer is looking for.

- Visit the company’s website

- Read industry publications

- Talk to people who work for the company

2. Practice answering common interview questions

Once you have a good understanding of the company and the position, you can start practicing answering common interview questions. This will help you feel more confident and prepared during your interview.

- Tell me about yourself.

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your experience with barratte machines?

- How do you handle stress?

3. Dress professionally and arrive on time

First impressions matter, so it’s important to dress professionally and arrive on time for your interview. This shows the interviewer that you’re serious about the position and that you respect their time.

4. Be yourself and be enthusiastic

The most important thing is to be yourself and be enthusiastic about the position. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Let your personality shine through and show the interviewer why you’re the best person for the job.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Barratte Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Barratte Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.