Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Aircraft Plumbing and Hydraulic Mechanic interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Aircraft Plumbing and Hydraulic Mechanic so you can tailor your answers to impress potential employers.

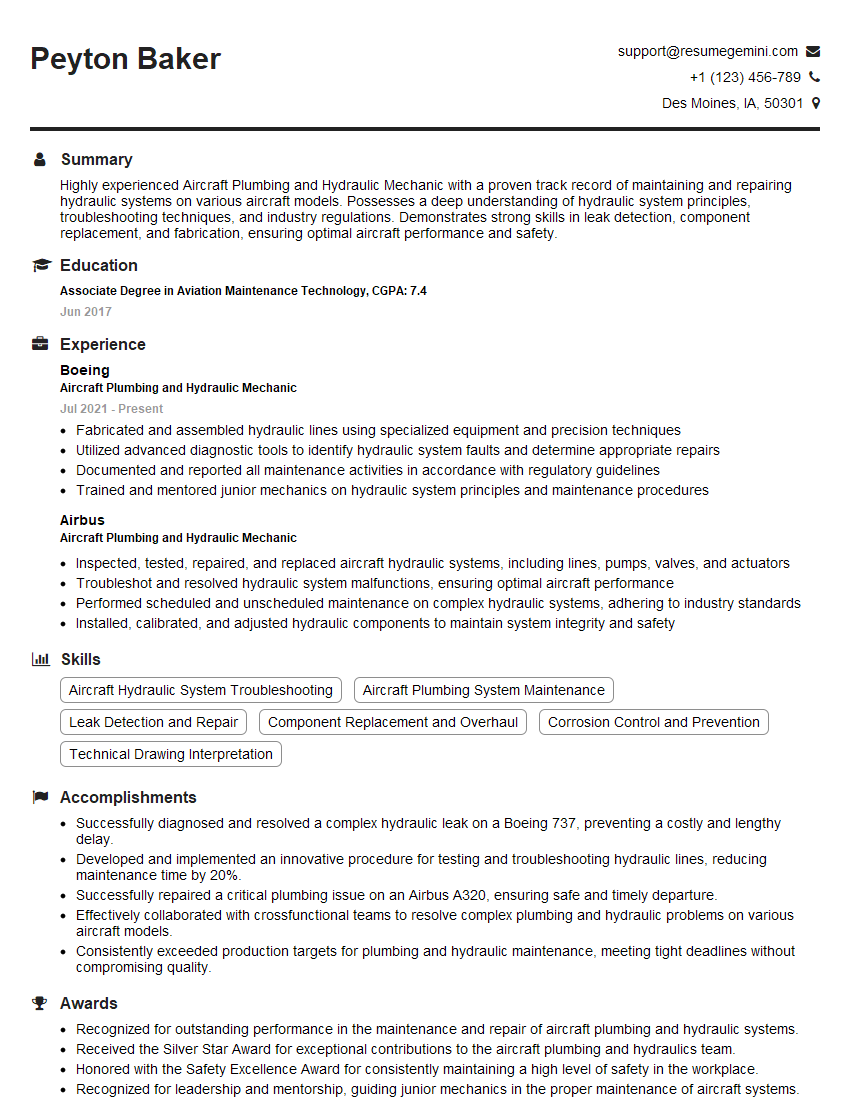

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Aircraft Plumbing and Hydraulic Mechanic

1. Explain the purpose and function of an aircraft hydraulic system?

The primary purpose of an aircraft hydraulic system is to transmit power from a central source to actuate various aircraft systems and components. It provides hydraulic fluid under pressure to power systems such as flight controls, landing gear, brakes, and wing flaps, enabling these components to operate efficiently and reliably.

- Transmit power from a centralized source

- Power various aircraft systems and components (e.g., flight controls, landing gear, brakes)

- Provide hydraulic fluid under pressure for smooth and reliable operation

2. Describe the different types of hydraulic fluids used in aircraft and their properties?

Petroleum-based fluids

- Mineral oil-based: Widely used, good lubrication properties, high flash point

- Synthetic hydrocarbons: Improved thermal stability and fire resistance

Synthetic fluids

- Phosphate esters: High fire resistance, good low-temperature performance

- Silicones: Inert, high-temperature stability, low flammability

3. What are the common materials used in aircraft plumbing and their properties?

- Aluminum: Lightweight, corrosion-resistant, easy to fabricate

- Steel: Strong, durable, used for high-pressure lines

- Titanium: High strength-to-weight ratio, corrosion-resistant, expensive

- Composite materials: Lightweight, corrosion-resistant, used for non-critical applications

4. What are the different types of aircraft plumbing joints and their applications?

- Flared joints: Used for low-pressure lines, easy to assemble

- Compression joints: Used for high-pressure lines, provide a leak-proof seal

- Pipe threads: Used for connecting pipes, require sealant to prevent leaks

- Welded joints: Used for permanent connections, provide a strong and durable seal

5. Explain the process of bleeding an aircraft hydraulic system?

- Open the bleed ports at the highest points of the system

- Pump hydraulic fluid into the system while monitoring for air bubbles

- Close the bleed ports once all air has been removed

- Check for leaks and ensure proper system operation

6. What are the safety precautions to consider when working with aircraft hydraulic systems?

- Wear appropriate personal protective equipment (PPE)

- Handle hydraulic fluids with care, as they can be flammable and toxic

- Never work on a pressurized hydraulic system

- Follow all established safety procedures

- Use proper tools and equipment

7. Describe the troubleshooting process for an aircraft hydraulic system?

- Identify the problem and isolate the affected area

- Check for leaks, loose connections, or damaged components

- Use diagnostic equipment to pinpoint the source of the issue

- Repair or replace faulty components

- Retest the system to ensure proper operation

8. What are the maintenance requirements for aircraft plumbing and hydraulic systems?

- Regular inspections for leaks, corrosion, and wear

- Periodic testing and flushing of the system

- Replacement of worn or damaged components

- Adherence to manufacturer’s maintenance schedules

9. Describe the importance of proper documentation in aircraft plumbing and hydraulic maintenance?

- Provides a record of maintenance activities

- Ensures compliance with regulatory requirements

- Facilitates troubleshooting and repair

- Helps prevent errors and improve safety

10. Explain the role of technology in modern aircraft plumbing and hydraulic systems?

- Advanced sensors for monitoring system parameters

- Computer-controlled systems for automation and optimization

- Simulation tools for design and testing

- Improved materials and fabrication techniques for enhanced performance

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Aircraft Plumbing and Hydraulic Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Aircraft Plumbing and Hydraulic Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Aircraft Plumbing and Hydraulic Mechanics play a crucial role in maintaining the safety and functionality of aircraft. Their responsibilities encompass a wide range of tasks, including:

1. Troubleshooting and Repairing Complex Systems

Identifying and diagnosing issues within plumbing and hydraulic systems. Utilizing specialized tools and techniques to repair or replace faulty components, ensuring optimal performance and preventing failures.

2. Installing and Maintaining Plumbing and Hydraulic Systems

Adhering to strict aviation regulations and standards. Installing, modifying, and repairing pipes, hoses, valves, and other components. Conducting routine inspections and preventive maintenance to ensure system integrity.

3. Ensuring Compliance with Safety Regulations

Prioritizing safety. Adhering to all applicable regulations, including the Federal Aviation Administration (FAA) and industry standards. Maintaining a deep understanding of safety protocols and procedures.

4. Working Collaboratively with Other Departments

Coordinating with other maintenance personnel, such as electricians and sheet metal workers. Exchanging technical information and providing support to ensure efficient aircraft maintenance and repair.

5. Continuous Learning and Professional Development

Staying abreast of advancements in aircraft technology and maintenance practices. Attending training programs, workshops, and certifications. Expanding knowledge and skills to maintain proficiency.

Interview Tips

Preparing thoroughly for an interview for an Aircraft Plumbing and Hydraulic Mechanic position is essential. Here are some interview tips to help you ace the interview and showcase your skills and experience:

1. Highlight Your Relevant Experience and Skills

Carefully review the job description and identify the key responsibilities and qualifications required for the position. Tailor your resume and cover letter to highlight your relevant experience and skills that align with these requirements. Quantify your accomplishments whenever possible to demonstrate the impact of your work.

2. Research the Company and Industry

Demonstrate your interest and enthusiasm for the position by researching the company and the industry. Familiarize yourself with their mission, values, and recent developments. Showcase your understanding of the company’s goals and how your skills and experience can contribute to their success.

3. Practice Answering Common Interview Questions

Prepare thoughtful responses to common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?” Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples that highlight your abilities.

4. Ask Thoughtful Questions

At the end of the interview, asking thoughtful questions shows your engagement and interest in the position. Prepare questions that delve into the company’s culture, growth opportunities, and specific details about the role. This demonstrates your enthusiasm and desire to learn more about the position.

5. Be Confident and Professional

Throughout the interview, maintain a confident and professional demeanor. Dress appropriately, make eye contact, and articulate your thoughts clearly and concisely. Be respectful of the interviewer’s time and show gratitude for the opportunity to interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Aircraft Plumbing and Hydraulic Mechanic interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!