Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Asphalt Mixer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

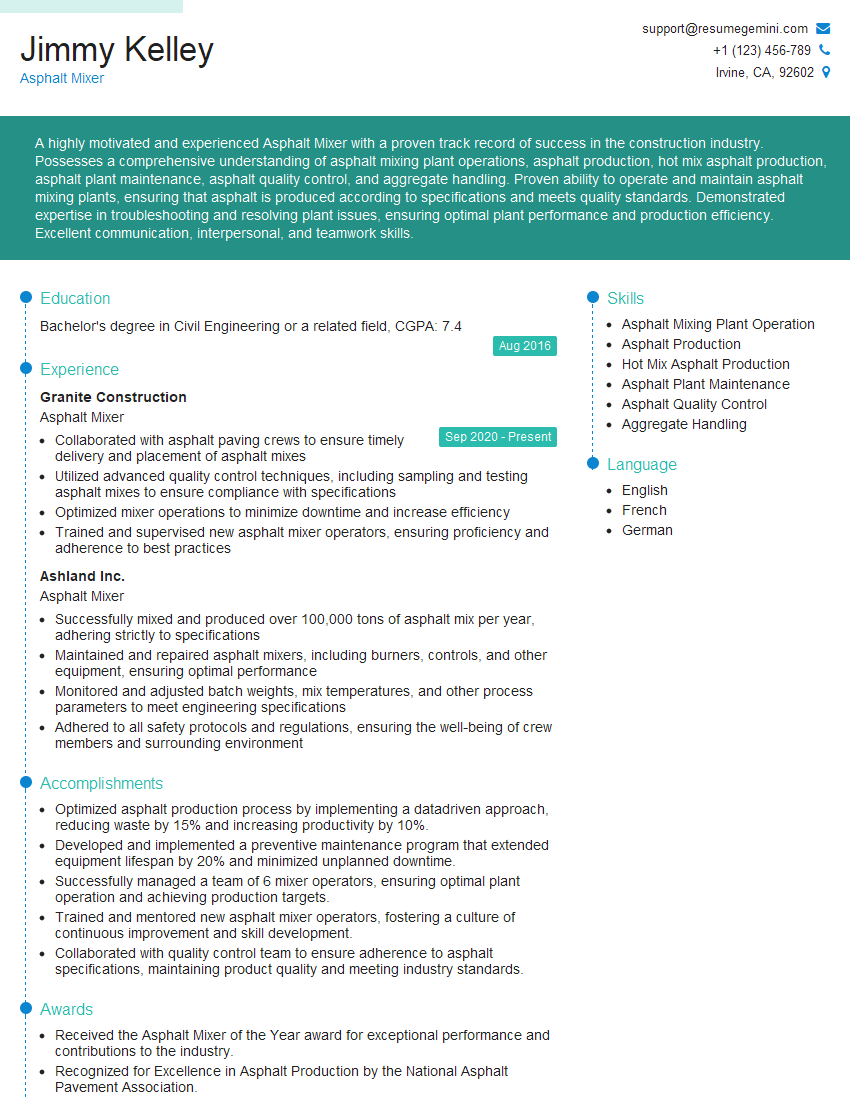

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Asphalt Mixer

1. What are the different types of asphalt mixtures and their applications?

There are many types of asphalt mixtures, each with its own unique properties and applications. Some of the most common types include:

- Hot mix asphalt (HMA): HMA is a type of asphalt mixture that is produced at high temperatures and then compacted to create a dense, durable surface. HMA is commonly used on highways, parking lots, and airports.

- Warm mix asphalt (WMA): WMA is a type of asphalt mixture that is produced at lower temperatures than HMA. This makes it more environmentally friendly and easier to work with, but it can also result in a slightly less durable surface.

- Cold mix asphalt (CMA): CMA is a type of asphalt mixture that is produced at ambient temperatures. This makes it easy to work with and store, but it can also result in a less durable surface than HMA or WMA.

- Mastic asphalt: Mastic asphalt is a type of asphalt mixture that is made with a high percentage of filler material, such as sand or limestone. This makes it very durable and resistant to wear and tear, but it can also be more expensive than other types of asphalt mixtures.

2. What are the key factors that affect the quality of an asphalt mixture?

Material properties

- The quality of the asphalt binder

- The gradation of the aggregate

- The amount of air voids in the mixture

Production process

- The temperature at which the mixture is produced

- The mixing time

- The compaction process

Environmental conditions

- The temperature

- The humidity

- The wind

3. What are the most common problems that can occur during the production of asphalt mixtures?

- Segregation: This occurs when the different components of the asphalt mixture separate during production or transportation. Segregation can lead to a weak and uneven surface.

- Bleeding: This occurs when the asphalt binder rises to the surface of the mixture. Bleeding can make the surface slippery and can also lead to cracking.

- Raveling: This occurs when the aggregate particles in the asphalt mixture become loose and fall off the surface. Raveling can make the surface rough and uneven.

- Rutting: This occurs when the asphalt mixture is deformed under traffic loads. Rutting can make the surface uneven and can also lead to safety hazards.

4. How can you prevent or minimize the occurrence of these problems?

- Segregation: Segregation can be prevented by ensuring that the asphalt mixture is properly mixed and transported. It can also be minimized by using a mixture with a narrow gradation of aggregate.

- Bleeding: Bleeding can be prevented by using a mixture with the correct asphalt content. It can also be minimized by using an asphalt binder with a high viscosity.

- Raveling: Raveling can be prevented by using a mixture with a high percentage of coarse aggregate. It can also be minimized by using an asphalt binder with a high viscosity.

- Rutting: Rutting can be prevented by using a mixture with a high stability. It can also be minimized by using an asphalt binder with a high viscosity.

5. What are the different tests that can be used to evaluate the quality of an asphalt mixture?

- Marshall stability test: This test measures the resistance of an asphalt mixture to permanent deformation under load.

- Hveem stability test: This test measures the resistance of an asphalt mixture to shoving under load.

- Asphalt content test: This test measures the amount of asphalt binder in an asphalt mixture.

- Aggregate gradation test: This test measures the distribution of aggregate particles in an asphalt mixture.

- Air voids test: This test measures the amount of air voids in an asphalt mixture.

6. What are the different types of equipment that are used to produce asphalt mixtures?

- Asphalt plant: This is the main piece of equipment used to produce asphalt mixtures. Asphalt plants can be either batch or continuous.

- Aggregate feeder: This equipment feeds the aggregate into the asphalt plant.

- Asphalt binder feeder: This equipment feeds the asphalt binder into the asphalt plant.

- Mixer: This equipment mixes the aggregate and asphalt binder together.

- Compactor: This equipment compacts the asphalt mixture into place.

7. What are the safety precautions that should be taken when working with asphalt mixtures?

- Asphalt mixtures are hot and can cause burns. Workers should wear protective clothing, including gloves, long sleeves, and pants.

- Asphalt fumes can be harmful if inhaled. Workers should wear respirators when working in areas with high levels of asphalt fumes.

- Asphalt mixtures can be slippery. Workers should be careful when walking on asphalt surfaces, especially when they are wet.

- Asphalt mixtures can contain hazardous chemicals. Workers should avoid skin contact with asphalt mixtures and should wash their hands thoroughly after working with them.

8. What are the environmental regulations that apply to the production and use of asphalt mixtures?

- The Clean Air Act: This act regulates the emission of air pollutants, including those from asphalt plants.

- The Clean Water Act: This act regulates the discharge of pollutants into water bodies, including those from asphalt plants.

- The Resource Conservation and Recovery Act: This act regulates the disposal of hazardous waste, including asphalt mixtures.

9. What are the latest trends in the asphalt industry?

- The use of recycled materials in asphalt mixtures: This is becoming increasingly common as a way to reduce costs and conserve resources.

- The development of new asphalt binders: This is being done to improve the performance and durability of asphalt mixtures.

- The use of new technologies to produce and place asphalt mixtures: This is being done to improve the efficiency and quality of the asphalt paving process.

10. What are the career opportunities for asphalt mixers?

- Asphalt plant operator

- Asphalt paver operator

- Asphalt inspector

- Asphalt sales representative

- Asphalt research and development engineer

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Asphalt Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Asphalt Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Asphalt Mixer is responsible for operating and maintaining asphalt mixing equipment to produce asphalt for road construction and repair projects.

1. Equipment Operation

The Asphalt Mixer is responsible for the safe and efficient operation of the asphalt mixing plant. This includes:

- Setting up and calibrating the equipment

- Loading the plant with asphalt, aggregates, and other materials

- Monitoring the mixing process and making adjustments as needed

- Ensuring that the asphalt mix meets the required specifications

- Troubleshooting and repairing equipment problems

2. Plant Maintenance

The Asphalt Mixer is also responsible for maintaining the asphalt mixing plant. This includes:

- Cleaning and lubricating the equipment

- Inspecting the equipment for wear and tear

- Making minor repairs and adjustments

- Ordering and installing replacement parts

3. Quality Control

The Asphalt Mixer is responsible for ensuring that the asphalt mix meets the required specifications. This includes:

- Taking samples of the asphalt mix and testing it

- Making adjustments to the mixing process as needed

- Reporting any quality control issues to the supervisor

4. Safety

The Asphalt Mixer is responsible for maintaining a safe work environment. This includes:

- Following all safety procedures

- Wearing appropriate safety gear

- Keeping the work area clean and free of hazards

- Reporting any safety concerns to the supervisor

Interview Tips

Preparing for an interview can be nerve-wracking, but by following these tips, you can increase your chances of success.

1. Research the Company and Position

Before the interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and what they are looking for in a candidate.

- Visit the company’s website

- Read articles about the company

- Talk to people who work for the company

- Prepare questions to ask the interviewer

2. Practice Your Answers

Once you have researched the company and the position, take some time to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview. Think about your skills and experience, and how they relate to the job requirements.

- Write out your answers to common interview questions

- Practice answering questions out loud

- Ask a friend or family member to give you feedback on your answers

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothing that is appropriate for the company culture. You should also make sure that your shoes are clean and polished.

- Choose clothes that are comfortable and allow you to move around easily

- Avoid wearing clothes that are too revealing or too casual

- Make sure your clothes are clean and pressed

- Wear shoes that are clean and polished

4. Be Polite and Respectful

Throughout the interview, it is important to be polite and respectful to the interviewer. This means being on time for the interview, making eye contact, and listening attentively to the interviewer’s questions. You should also be honest and upfront about your skills and experience.

- Arrive on time for your interview

- Make eye contact with the interviewer

- Listen attentively to the interviewer’s questions

- Be honest and upfront about your skills and experience

5. Follow Up

After the interview, it is important to follow up with the interviewer. This shows that you are interested in the position and that you are serious about your application. You can follow up by sending a thank-you note or by calling the interviewer to check on the status of your application.

- Send a thank-you note to the interviewer

- Call the interviewer to check on the status of your application

- Stay positive and don’t give up

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Asphalt Mixer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Asphalt Mixer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.