Feeling lost in a sea of interview questions? Landed that dream interview for Automated Equipment Engineer-Technician but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Automated Equipment Engineer-Technician interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

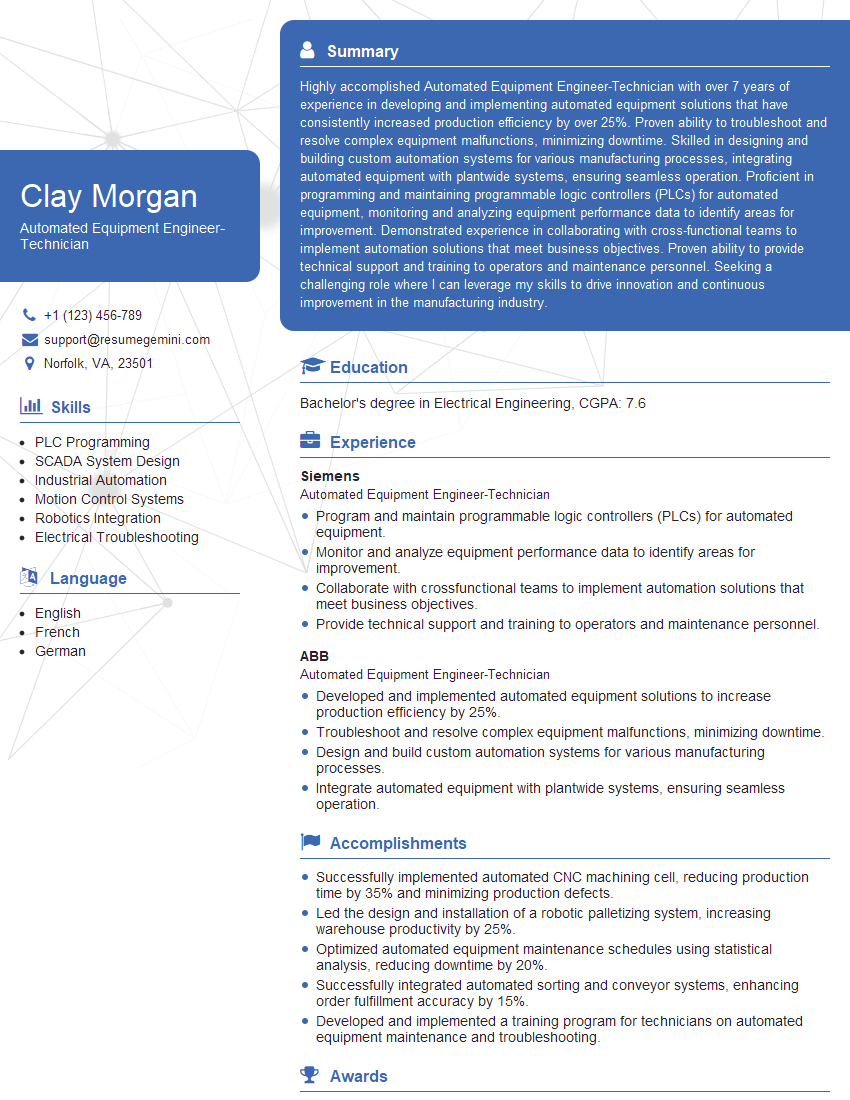

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Automated Equipment Engineer-Technician

1. Can you describe your experience in PLC programming for automated equipment?

In my previous role, I was responsible for developing and maintaining PLC programs for a variety of automated equipment. I have experience with ladder logic, function block programming, and structured text programming. I am proficient in using RSLogix 5000 and Siemens TIA Portal. I have a strong understanding of PLC hardware, including I/O modules, power supplies, and communication networks.

2. What are the different types of sensors used in automated equipment?

There are many different types of sensors used in automated equipment. Some of the most common types include:

- Proximity sensors: Detect the presence or absence of an object without physical contact.

- Photoelectric sensors: Detect the interruption or reflection of a light beam.

- Limit switches: Detect the position of a moving object.

- Encoders: Measure the position and speed of a rotating shaft.

- Temperature sensors: Measure the temperature of a process or environment.

- Pressure sensors: Measure the pressure of a fluid or gas.

- Flow sensors: Measure the flow rate of a fluid or gas.

- Level sensors: Measure the level of a liquid or solid in a tank or container.

3. How do you troubleshoot an automated system?

There are several steps involved in troubleshooting an automated system:

- Gather information: Collect as much information as possible about the system, including the PLC program, electrical schematics, and mechanical drawings.

- Identify the problem: Determine the symptoms of the problem and try to identify the root cause.

- Test the system: Perform tests to verify the problem and identify any contributing factors.

- Make repairs: Once the root cause of the problem has been identified, make the necessary repairs.

- Test the system again: After making repairs, test the system again to ensure that the problem has been resolved.

4. What are the different types of automated equipment?

There are many different types of automated equipment, including:

- Industrial robots: Used for a variety of tasks, such as welding, assembly, and material handling.

- Automated guided vehicles (AGVs): Used to transport materials and products within a facility.

- Machine tools: Used to perform a variety of machining operations, such as turning, milling, and drilling.

- Conveyor systems: Used to transport materials and products from one location to another.

- Packaging machines: Used to package products for sale.

- Automated storage and retrieval systems (AS/RS): Used to store and retrieve materials and products in a warehouse.

5. What is the difference between a PLC and a DCS?

A PLC (Programmable Logic Controller) is a small, self-contained computer that is used to control automated equipment. A DCS (Distributed Control System) is a large, networked system that is used to control complex processes, such as those found in power plants and chemical plants.

Advantages of PLCs

- Lower cost

- Easier to program

- More flexible

Advantages of DCSs

- Higher reliability

- Greater scalability

- More powerful

6. What are the latest trends in automation technology?

Some of the latest trends in automation technology include:

- Industrial Internet of Things (IIoT): The use of sensors and other devices to collect data from automated equipment and connect it to the Internet.

- Artificial intelligence (AI): The use of AI techniques to improve the performance of automated systems.

- Cobots: Collaborative robots that work alongside human workers.

- Edge computing: The use of small, powerful computers to process data closer to the source.

7. What are some of the challenges of working as an automated equipment engineer-technician?

Some of the challenges of working as an automated equipment engineer-technician include:

- The need to keep up with the latest technology: Automation technology is constantly evolving, so it is important to stay up-to-date with the latest trends.

- The need to work with a variety of equipment: Automated equipment engineers-technicians must be able to work with a variety of equipment, from PLCs to robots to sensors.

- The need to troubleshoot complex problems: Automated equipment can be complex, and troubleshooting problems can be challenging.

- The need to work in a fast-paced environment: Automated equipment is often used in critical applications, so it is important to be able to work quickly and efficiently.

8. What are your strengths as an automated equipment engineer-technician?

Some of my strengths as an automated equipment engineer-technician include:

- Strong knowledge of PLC programming

- Proficient in electrical troubleshooting

- Experience with a variety of automated equipment

- Ability to work independently and as part of a team

- Excellent communication and interpersonal skills

9. What are your career goals?

My career goals are to become a lead automated equipment engineer-technician and eventually a manager. I am passionate about automation and I am always looking for new ways to improve my skills and knowledge.

10. Do you have any questions for me?

I do have a few questions for you:

- What is the most challenging project you have worked on?

- What is the company’s culture like?

- What are the opportunities for advancement?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Automated Equipment Engineer-Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Automated Equipment Engineer-Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Automated Equipment Engineer-Technician is a highly skilled professional responsible for designing, installing, maintaining, and troubleshooting automated equipment in various industrial settings.

1. Equipment Design and Development

Contribute to the design and development of automated equipment and systems, ensuring they meet specifications and industry standards.

- Create design concepts, generate technical drawings, and develop prototypes.

- Analyze and select components, materials, and software for automated systems.

2. Installation and Commissioning

Supervise the installation and commissioning of automated equipment, ensuring it operates according to specifications.

- Plan and coordinate equipment installation and integration with existing systems.

- Calibrate and test equipment to ensure proper functionality and safety.

3. Maintenance and Troubleshooting

Perform preventive maintenance and troubleshoot automated equipment to minimize downtime and ensure optimal performance.

- Inspect, clean, and lubricate equipment to maintain its reliability.

- Identify and resolve equipment malfunctions using diagnostic tools and techniques.

4. Process Optimization

Monitor and analyze equipment performance and identify areas for process optimization.

- Develop and implement strategies to improve productivity, efficiency, and quality.

- Collaborate with engineers and other technicians to optimize automated processes.

Interview Tips

Preparing thoroughly for your interview can significantly improve your chances of success. Here are some tips to help you ace the interview and showcase your qualifications as an Automated Equipment Engineer-Technician:

1. Research the Company and Role

Familiarize yourself with the company’s background, industry, and values. Understand the specific requirements and responsibilities of the Automated Equipment Engineer-Technician role.

- Visit the company’s website, LinkedIn page, and industry publications.

- Analyze the job description and identify the key skills and experience needed.

2. Highlight Your Technical Expertise

During the interview, emphasize your technical skills and experience in designing, installing, maintaining, and troubleshooting automated equipment.

- Provide specific examples of projects where you have successfully implemented automated solutions.

- Demonstrate your knowledge of industry standards, regulations, and best practices.

3. Showcase Your Problem-Solving Abilities

Interviewers will be keen to assess your problem-solving skills and ability to handle technical challenges.

- Share examples from your past experience where you identified, diagnosed, and resolved equipment issues.

- Explain your approach to troubleshooting and how you prioritize and manage multiple tasks.

4. Quantify Your Accomplishments

Whenever possible, use specific metrics to quantify your accomplishments and demonstrate the impact of your work.

- For example, instead of stating that you improved equipment reliability, specify the percentage reduction in downtime.

- Highlight how your contributions have led to increased productivity or cost savings.

Next Step:

Now that you’re armed with the knowledge of Automated Equipment Engineer-Technician interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Automated Equipment Engineer-Technician positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini