Are you gearing up for an interview for a Banbury Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Banbury Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

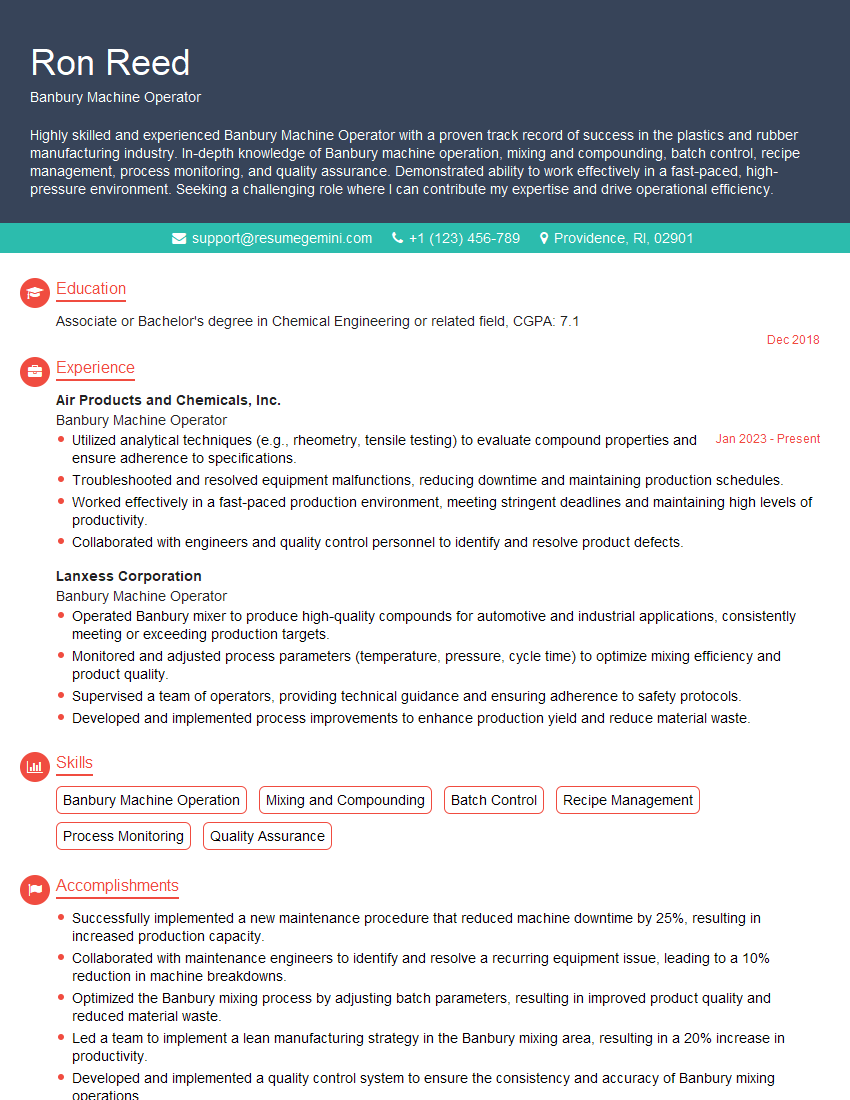

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Banbury Machine Operator

1. What are the key components of a Banbury mixer?

The key components of a Banbury mixer include:

- Mixing chamber

- Rotors

- Ram

- Temperature control system

- Safety features

2. What is the difference between a two-roll mill and a Banbury mixer?

Two-Roll Mill

- Consists of two horizontally mounted rolls

- Rolls rotate in opposite directions

- Material is fed into the nip between the rolls

- Shearing action of the rolls mixes the material

Banbury Mixer

- Consists of two intermeshing rotors

- Rotors rotate at high speed

- Material is fed into the mixing chamber

- High shear and kneading action of the rotors mixes the material

3. What are the different types of Banbury mixers?

The different types of Banbury mixers include:

- Standard Banbury mixers

- Intensive Banbury mixers

- Continuous Banbury mixers

4. What are the benefits of using a Banbury mixer?

The benefits of using a Banbury mixer include:

- High mixing efficiency

- Uniform mixing

- Short mixing time

- Ability to handle a wide range of materials

- Versatile operation

5. What are the safety precautions that must be taken when operating a Banbury mixer?

The safety precautions that must be taken when operating a Banbury mixer include:

- Wear appropriate personal protective equipment (PPE)

- Follow all manufacturer’s instructions

- Never operate the mixer unless it is in good working condition

- Keep the work area clean and free of debris

- Be aware of the hazards of the materials being mixed

6. What are the common problems that can occur with Banbury mixers?

The common problems that can occur with Banbury mixers include:

- Rotor wear

- Ram wear

- Temperature control problems

- Hydraulic system problems

- Electrical system problems

7. How do you troubleshoot a Banbury mixer that is not mixing properly?

To troubleshoot a Banbury mixer that is not mixing properly, the following steps can be taken:

- Check the rotor speed

- Check the ram pressure

- Check the temperature of the mixing chamber

- Check the hydraulic system

- Check the electrical system

8. What is the maintenance schedule for a Banbury mixer?

The maintenance schedule for a Banbury mixer should be in accordance with the manufacturer’s recommendations. Typically, this includes:

- Daily inspections

- Weekly inspections

- Monthly inspections

- Quarterly inspections

- Annual inspections

9. What are the key performance indicators (KPIs) for a Banbury mixer?

The key performance indicators (KPIs) for a Banbury mixer include:

- Mixing time

- Product quality

- Energy consumption

- Maintenance costs

- Safety record

10. What are the future trends in Banbury mixer technology?

The future trends in Banbury mixer technology include:

- Increased automation

- Improved safety features

- More efficient energy consumption

- Greater use of data analytics

- Development of new materials

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Banbury Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Banbury Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Banbury Machine Operators play a pivotal role in the production process of rubber and plastic products. Their primary duties involve operating and maintaining Banbury mixers, which are specialized machines used to blend and compound raw materials.

1. Machine Operation and Maintenance

Banbury Machine Operators are responsible for the safe and efficient operation of Banbury mixers. They monitor the mixing process, adjust process parameters, and perform routine maintenance and repairs to ensure optimal performance.

- Load and unload raw materials into the Banbury mixer

- Set and adjust mixing parameters based on product specifications

- Monitor temperature, pressure, and other process variables

- Perform basic troubleshooting and repairs on Banbury mixers

2. Quality Control

Banbury Machine Operators are responsible for the quality of the blended materials produced by the Banbury mixer. They perform quality checks to ensure that the products meet the desired specifications.

- Take samples of mixed materials for quality testing

- Analyze test results and make adjustments to the mixing process as needed

- Monitor the consistency and uniformity of the mixed materials

3. Safety and Compliance

Banbury Machine Operators work in a potentially hazardous environment. They are responsible for adhering to safety protocols, maintaining a clean and organized work area, and using personal protective equipment.

- Follow established safety procedures and wear appropriate protective gear

- Maintain a clean and organized work area to prevent accidents

- Report any safety hazards or concerns to supervisors

4. Teamwork and Communication

Banbury Machine Operators often work as part of a team. They are responsible for communicating effectively with other operators, supervisors, and production staff.

- Collaborate with team members to ensure smooth production flow

- Communicate any issues or concerns to supervisors in a timely manner

- Provide training and support to new or less experienced operators

Interview Preparation Tips

Preparing for an interview for a Banbury Machine Operator position requires both technical knowledge and presentation skills. Here are some essential preparation tips:

1. Research the Company and Position

Take the time to research the company, its products, and the specific job requirements. Understanding the company’s culture and the expectations of the role will help you tailor your answers and demonstrate your interest.

- Visit the company website and read about their history, mission, and products

- Review the job description carefully and identify key responsibilities

- Look for news articles or industry reports about the company and its market position

2. Practice Your Answers

Prepare thoughtful and concise answers to common interview questions. Practice your responses out loud to improve your delivery and confidence.

- Prepare for questions about your experience operating Banbury mixers

- Practice describing your quality control procedures and problem-solving skills

- Be ready to discuss your commitment to safety and teamwork

3. Emphasize Transferable Skills

If you don’t have direct experience operating a Banbury mixer, highlight transferable skills such as process monitoring, quality control, and teamwork. These skills are essential for any manufacturing environment.

- Discuss your experience with similar machinery or in a related industry

- Emphasize your ability to quickly learn new processes and adapt to changing conditions

- Share examples of how you have successfully worked in a team environment

4. Dress Professionally and Be Punctual

First impressions matter. Dress professionally, arrive on time for your interview, and maintain polite and respectful behavior throughout the process. These small details can make a positive impact on the interviewer.

- Choose attire that is clean, pressed, and appropriate for a manufacturing environment

- Plan your route and give yourself plenty of time to arrive at the interview location

- Be courteous and respectful to everyone you meet, including the receptionist and other staff

Next Step:

Now that you’re armed with the knowledge of Banbury Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Banbury Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini