Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Banbury Mill Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

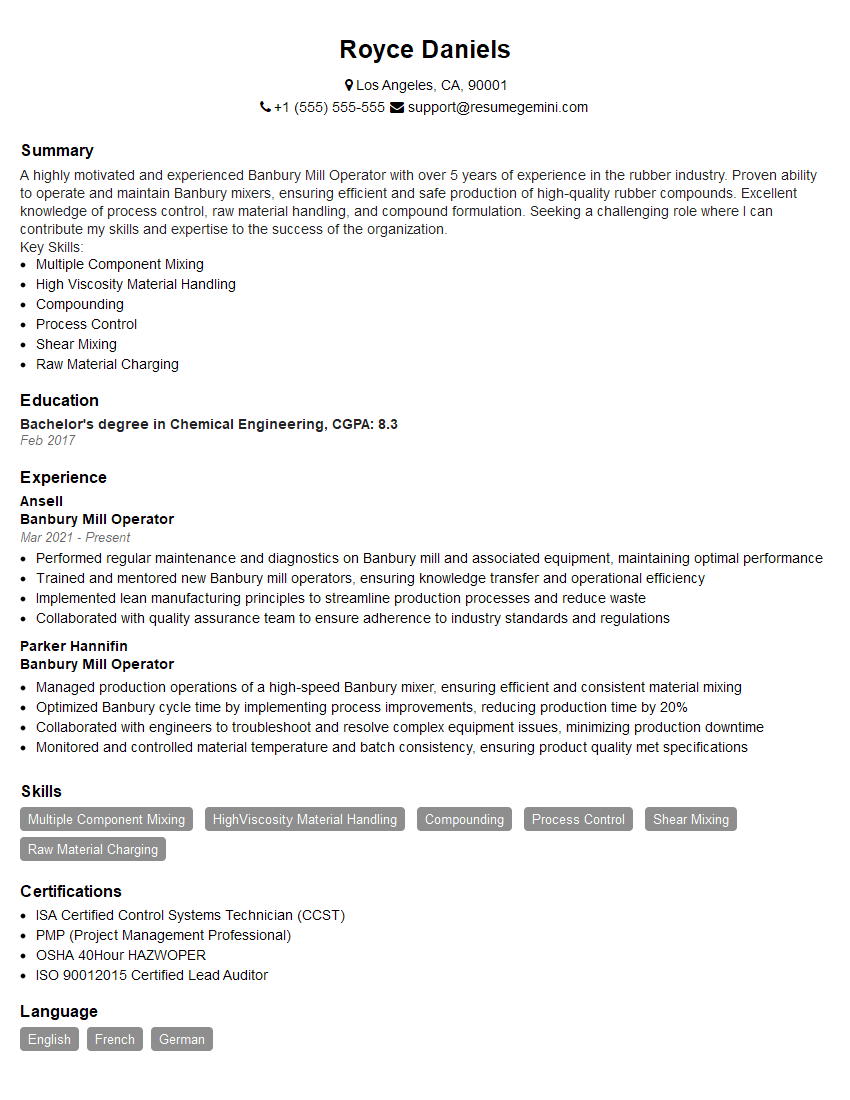

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Banbury Mill Operator

1. Describe the process of compound preparation in a Banbury mill?

In a Banbury mill, compound preparation involves several key steps:

- Loading the mill: The Banbury mill is charged with the required raw materials, such as polymers, fillers, pigments, and additives, in specific proportions.

- Mixing: The mill’s rotating blades mix and shear the materials together, creating a homogeneous mixture. The speed and temperature of the mill are carefully controlled to achieve the desired properties.

- Milling: The mixing process continues until the compound reaches the desired consistency, which is determined by factors such as the formulation, temperature, and shear forces applied.

- Discharge: Once the compound is properly mixed and milled, it is discharged from the mill. The discharge temperature and pressure are monitored to ensure optimal quality.

2. How do you determine the optimal speed and temperature settings for a Banbury mill?

Determining the optimal speed and temperature settings for a Banbury mill requires considering several factors:

Formulation:

- The type and composition of the raw materials influence the ideal mixing and milling parameters.

Temperature:

- Temperature affects the viscosity and flow properties of the compound, and it must be carefully controlled to prevent overheating or degradation.

- Higher temperatures can accelerate the mixing process but may also increase the risk of scorching or cross-linking.

Speed:

- Speed determines the intensity of shear forces applied to the compound.

- Higher speeds can improve mixing efficiency but may also increase energy consumption and wear on the mill.

3. What are the potential troubleshooting issues that can occur during Banbury mill operation, and how do you address them?

Various issues can arise during Banbury mill operation, including:

- Overheating: Excessive temperature can lead to compound degradation or damage to the mill’s components. Monitoring temperature and adjusting settings accordingly is crucial.

- Undermixing: Inadequate mixing results in non-uniform compound properties. Optimization of mixing parameters and inspection of the compound’s homogeneity can help prevent this issue.

- Motor overloading: High torque or excessive material loading can overload the motor. Proper maintenance, load monitoring, and adherence to operating guidelines are necessary.

- Blade wear: Blades experience wear over time, affecting mixing efficiency. Regular inspection and replacement of worn blades are essential.

4. Explain the importance of maintaining proper seals and gaskets in a Banbury mill?

Properly maintained seals and gaskets are vital for the safe and efficient operation of a Banbury mill. They prevent the following:

- Leakage: Seals and gaskets prevent the escape of materials from the mill, ensuring proper mixing and preventing contamination.

- Contamination: They protect the compound from external contaminants entering the mill, maintaining the integrity and quality of the mixture.

- Pressure loss: Proper sealing ensures that the mill operates at the correct pressure, optimizing mixing efficiency.

- Safety hazards: Leaks or ruptures in seals and gaskets can create safety risks, such as exposure to hazardous materials or high-pressure fluids.

5. Describe the safety precautions you take when operating a Banbury mill?

When operating a Banbury mill, the following safety precautions are essential:

- PPE: Wearing appropriate personal protective equipment (PPE), such as gloves, safety glasses, and earplugs, is crucial.

- Machine guarding: Never operate the mill with safety guards removed or bypassed.

- Electrical safety: Ensure proper electrical grounding and lockout/tagout procedures are followed.

- Emergency shutdown: Be familiar with emergency shutdown procedures and know the location of the emergency stop buttons.

- Material handling: Handle raw materials and compounds carefully to prevent spills or accidents.

6. How do you ensure the quality of the compound produced by a Banbury mill?

To ensure compound quality, the following measures are critical:

- Raw material inspection: Inspect incoming raw materials for quality and conformance to specifications.

- Process monitoring: Monitor temperature, speed, and other process parameters during mixing and milling.

- Sampling and testing: Take samples of the compound at different stages of the process for testing properties such as viscosity, homogeneity, and mechanical strength.

- Record keeping: Maintain accurate records of process parameters, material usage, and test results for quality traceability.

7. Describe the maintenance procedures you perform on a Banbury mill?

Regular maintenance is crucial for optimal mill performance and includes the following procedures:

- Lubrication: Lubricate moving parts regularly according to the manufacturer’s recommendations.

- Blade inspection: Inspect blades for wear or damage and replace them as needed.

- Seal and gasket replacement: Replace worn or damaged seals and gaskets to prevent leaks and contamination.

- Electrical checks: Perform electrical checks to ensure proper grounding and wiring.

- Calibration: Calibrate temperature and pressure sensors regularly for accurate readings.

8. What are the advantages of using a Banbury mill over other mixing technologies?

Banbury mills offer several advantages over other mixing technologies, including:

- High shear forces: Banbury mills generate high shear forces, enabling effective mixing and dispersion of materials.

- Efficient heat transfer: The mill’s enclosed design facilitates efficient heat transfer, allowing temperature control during mixing.

- Versatility: Banbury mills can handle a wide range of materials and formulations, from plastics to rubber compounds.

- Closed system: The mill’s closed system prevents contamination and ensures a clean mixing environment.

9. What are the latest advancements in Banbury mill technology?

Recent advancements in Banbury mill technology include:

- Advanced control systems: Microprocessor-based control systems provide precise control over process parameters.

- Variable speed drives: Variable speed drives allow for optimization of mixing speed and torque.

- Improved blade designs: New blade designs enhance mixing efficiency and reduce energy consumption.

- Monitoring and diagnostics: Integrated sensors and diagnostic tools provide real-time monitoring and troubleshooting capabilities.

10. How do you stay updated on the latest industry best practices in Banbury mill operation?

To stay updated on industry best practices, I engage in the following activities:

- Industry publications: I subscribe to and read trade publications and technical journals dedicated to the rubber and plastics industry.

- Conferences and workshops: I attend industry conferences and workshops to learn about new technologies and best practices.

- Networking: I participate in industry networking events and connect with other professionals in the field to exchange ideas and knowledge.

- Online resources: I utilize online platforms and forums to access the latest technical information and best practices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Banbury Mill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Banbury Mill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Banbury Mill Operator plays a vital role in the production process within the rubber manufacturing industry. Here are some key job responsibilities:

1. Monitoring and Operating Machinery

Banbury Mill Operators are responsible for monitoring and operating Banbury mixers, which are large machines used to mix and compound rubber materials.

- Ensuring that the correct ingredients are added to the mixer in the correct proportions

- Setting and adjusting machine parameters, such as temperature, pressure, and mixing time

2. Quality Control

Maintaining the quality of the mixed rubber compounds is crucial.

- Taking samples of the mixed compound and performing quality control tests

- Making adjustments to the mixing process as needed to ensure that the desired specifications are met

3. Maintenance and Troubleshooting

Banbury Mill Operators are responsible for the basic maintenance and upkeep of the equipment they operate.

- Monitoring equipment for any signs of wear or damage

- Performing routine maintenance tasks, such as cleaning and lubricating equipment

- Troubleshooting and resolving any operational issues that may arise

4. Safety Procedures

Working with heavy machinery and hazardous materials requires strict adherence to safety protocols.

- Following established safety procedures and regulations

- Using appropriate personal protective equipment (PPE)

- Reporting any safety concerns or incidents

Interview Tips

To ace the Banbury Mill Operator interview, candidates should be well-prepared and highlight their relevant skills and experience.

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will give you a better understanding of the company’s culture, values, and expectations for the role.

- Visit the company’s website and social media pages

- Read industry news and articles to stay up-to-date on the latest trends and developments

2. Practice Answering Common Interview Questions

There are several common interview questions that candidates can expect in a Banbury Mill Operator interview. By practicing your answers to these questions, you can increase your confidence and deliver more effective responses.

- Tell me about your experience operating Banbury mixers.

- What are the most important safety procedures to follow when working with Banbury mixers?

3. Emphasize Your Skills and Experience

During the interview, be sure to highlight your relevant skills and experience that align with the job requirements. Quantify your accomplishments whenever possible to provide concrete evidence of your abilities.

- Use action verbs and specific examples to describe your experience

- Relate your skills and experience to the specific job responsibilities

4. Ask Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. It also gives you an opportunity to clarify any details about the role or the company.

- Ask about the company’s growth plans or industry outlook

- Inquire about opportunities for professional development or advancement

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Banbury Mill Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.