Are you gearing up for a career in Banbury Mixer Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Banbury Mixer Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

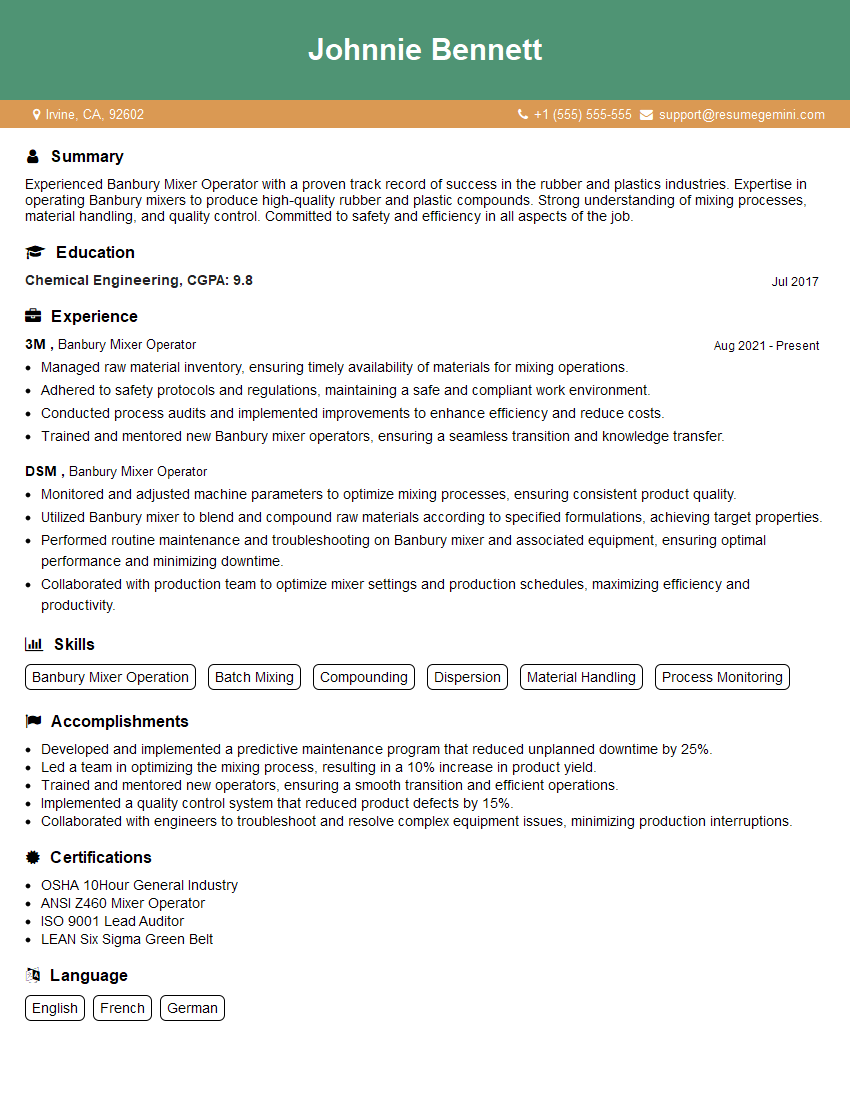

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Banbury Mixer Operator

1. Describe the key responsibilities of a Banbury Mixer Operator.

- Operating and monitoring Banbury mixers to ensure efficient mixing of rubber compounds.

- Maintaining and calibrating equipment to ensure optimal performance.

- Following established procedures and specifications to ensure product quality.

- Inspecting raw materials and finished products to ensure adherence to standards.

- Conducting regular cleaning and maintenance of equipment to prevent contamination and downtime.

- Troubleshooting and resolving issues that may arise during the mixing process.

2. What are the different types of Banbury mixers and their applications?

- Internal mixers: Used for intensive mixing of high-viscosity rubber compounds.

- External mixers: Used for mixing less viscous compounds or incorporating fillers.

- Intermixers: Combine features of both internal and external mixers for versatility.

- C-frame mixers: Designed for continuous mixing of large volumes of rubber compounds.

- Two-roll mills:Used for mixing, warming, and sheeting rubber compounds.

3. Explain the process of mixing rubber compounds in a Banbury mixer.

- Loading the mixer with raw materials according to established recipes.

- Setting the temperature, speed, and time parameters for the mixing cycle.

- Monitoring the mixing process and making adjustments as needed.

- Unloading the mixed compound and preparing it for further processing.

4. What are the critical quality control parameters to monitor during rubber mixing?

- Temperature: To ensure proper compound viscosity and curing properties.

- Mixing time: To achieve the desired level of dispersion and homogeneity.

- Speed: To control the intensity of mixing and prevent overheating.

- Batch weight: To ensure accurate quantities of raw materials are used.

- Visual inspection: To check for proper mixing, color, and consistency.

5. Describe the safety precautions that must be taken when operating a Banbury mixer.

- Wearing appropriate personal protective equipment (PPE) such as gloves, apron, and safety glasses.

- Guarding against moving parts and hot surfaces.

- Following lockout/tagout procedures when servicing or cleaning the mixer.

- Maintaining a clean and organized work area to prevent slips and falls.

- Being aware of potential hazards such as explosions, fires, and chemical spills.

6. What maintenance tasks are essential for ensuring the proper functioning of a Banbury mixer?

- Regularly cleaning and lubricating moving parts.

- Inspecting and replacing worn or damaged components.

- Calibrating sensors and controls to maintain accuracy.

- Checking and adjusting belt tension to prevent slippage.

- Performing preventive maintenance tasks as per manufacturer recommendations.

7. How do you troubleshoot common problems that may occur during rubber mixing?

- Overheating: Adjust mixing parameters, reduce batch size, or check cooling system.

- Undermixing: Increase mixing time, adjust speed or temperature.

- Scorching: Reduce mixing temperature, shorten mixing time.

- Contamination: Clean equipment thoroughly and inspect raw materials.

- Equipment failure: Follow lockout/tagout procedures and contact maintenance.

8. What are the key performance indicators (KPIs) used to measure the efficiency of a Banbury Mixer Operator?

- Product quality: Consistency, adherence to specifications.

- Production output: Amount of mixed rubber produced per hour.

- Downtime: Minimizing equipment failures and maintenance time.

- Energy consumption: Optimizing mixer settings to reduce energy usage.

- Waste reduction: Minimizing scrap and rework.

9. How do you stay updated with the latest developments and best practices in rubber mixing technology?

- Attending industry conferences and workshops.

- Reading technical journals and publications.

- Consulting with equipment manufacturers and experts.

- Participating in online forums and discussions.

- Seeking continuous education opportunities.

10. What are your career goals and how does this role align with your aspirations?

- Express enthusiasm for the rubber industry and Banbury mixing.

- Demonstrate understanding of the role’s responsibilities and how they align with your skills.

- Explain how the position provides opportunities for growth and advancement.

- Show commitment to the company and its mission.

- State your long-term career aspirations and how this role is a stepping stone.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Banbury Mixer Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Banbury Mixer Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Banbury Mixer Operators play a key role in the rubber and plastics industries, ensuring the production of high-quality compounds. Their primary responsibilities include:

1. Machine Operation

They operate and maintain Banbury mixers, which are high-powered machines used to blend and mix various raw materials into rubber compounds.

- Setting up and calibrating mixer parameters

- Monitoring and controlling the mixing process, including temperature, pressure, and duration

2. Material Handling

Handling raw materials and finished compounds, including loading, unloading, and ensuring proper storage.

- Receiving and inspecting raw materials

- Transporting compounds to storage or production areas

3. Quality Control

Conducting quality control checks on raw materials and finished products.

- Taking samples for testing

- Ensuring compliance with established quality standards

4. Maintenance and Troubleshooting

Performing routine maintenance and troubleshooting of Banbury mixers and related equipment.

- Cleaning and inspecting mixers

- Diagnosing and resolving equipment malfunctions

Interview Preparation Tips

To ace an interview for a Banbury Mixer Operator position, candidates should consider the following tips:

1. Research the Company and Industry

Demonstrate your interest in the company and the rubber/plastics industry. Research their products, market position, and recent developments.

2. Highlight Your Technical Skills

Emphasize your proficiency in operating and maintaining Banbury mixers. Mention any experience with different types of mixers, raw materials, and quality control procedures.

3. Showcase Your Attention to Detail

In this role, attention to detail is crucial. Provide examples of how you ensure accuracy in your work, such as following quality control standards and performing thorough inspections.

4. Prepare for Behavioral Questions

Interviewers may ask behavioral questions to assess your problem-solving, teamwork, and communication skills. Prepare stories that demonstrate your ability to handle stress, solve problems, and work effectively in a team.

5. Practice Common Interview Questions

Practice answering common interview questions, such as “Tell me about yourself” and “Why are you interested in this role?” Tailor your answers to the specific job requirements.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Banbury Mixer Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!