Feeling lost in a sea of interview questions? Landed that dream interview for Bonder but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Bonder interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

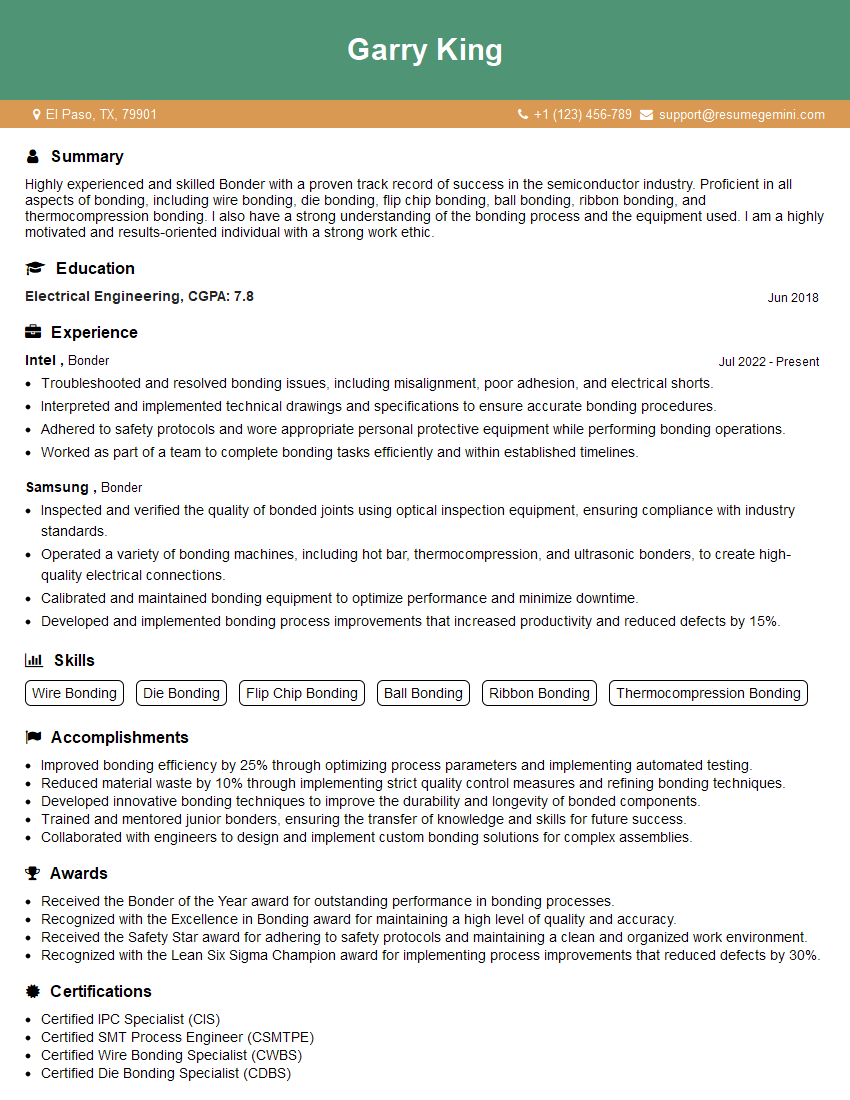

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Bonder

1. Describe a complex bonding process that you have successfully completed and discuss the challenges you encountered along the way?

– Worked on a project involving the bonding of two dissimilar materials, each with unique properties and joining requirements. – Faced challenges in achieving proper adhesion and maintaining bond strength while meeting specific tolerance specifications. – Conducted extensive material compatibility testing and developed innovative bonding techniques to ensure a robust and reliable bond.

2. What are the key factors that influence the selection of bonding adhesives and techniques?

Material Properties:

- Surface chemistry and reactivity

- Mechanical and thermal properties

Bonding Requirements:

- Strength and durability

- Environmental resistance

- Aesthetics

Processing Parameters:

- Curing time and temperature

- Surface preparation

- Application method

3. Explain the difference between structural and non-structural bonding adhesives?

– Structural adhesives: Form strong, durable bonds that can withstand high loads and are used in critical applications. They typically require precise surface preparation and may require curing under controlled conditions. – Non-structural adhesives: Less strong and more flexible, used for non-load-bearing applications. They offer flexibility, ease of application, and quick bond formation.

4. Describe the various bonding techniques you have experience with and the advantages and disadvantages of each?

- Adhesive bonding: Uses adhesives to join materials, offering high strength, durability, and flexibility.

- Mechanical bonding: Joins materials using physical fasteners such as rivets or bolts, providing high strength but potential for stress concentrations.

- Thermal bonding: Fuses materials together using heat, creating a permanent bond that is strong and resistant to external forces.

- Ultrasonic bonding: Uses high-frequency vibrations to induce molecular motion and create a solid-state bond, ideal for delicate materials.

5. Discuss the importance of quality control in bonding processes and the techniques used to ensure the integrity of bonded joints?

- Inspection: Visual and non-destructive testing methods to verify bond strength, surface quality, and joint geometry.

- Testing: Mechanical testing (e.g., tensile, shear, fatigue) to determine the performance of bonded joints under various loads.

- Environmental testing: Exposing bonded joints to extreme temperatures, humidity, or chemicals to evaluate durability.

- Process control: Monitoring and controlling critical process parameters (e.g., temperature, pressure, time) to ensure consistent and reliable bonding.

6. What are the latest advancements in bonding technology that you are familiar with?

- Nanotechnology: Use of nanoparticles and nanomaterials to enhance bond strength and adhesion.

- Plasma bonding: High-temperature plasma treatment to improve surface activation and bond formation.

- Laser bonding: Laser energy to create precise and localized bonds, reducing thermal damage and distortion.

- Self-healing adhesives: Adhesives with the ability to repair or regenerate damaged bonds.

7. Describe a time when you successfully resolved a bonding issue on a critical component?

– Encountered a bonding failure in a high-stress component during testing. – Conducted a thorough investigation to identify the root cause, which was an inadequate surface preparation process. – Implemented a new surface treatment protocol, resulting in a significant improvement in bond strength and reliability.

8. What are your knowledge of adhesive chemistry and how it relates to bonding processes?

– Understanding the chemical composition and properties of adhesives is crucial for selecting the appropriate adhesive for different applications. – Adhesive chemistry influences factors such as bond strength, durability, environmental resistance, and processing characteristics.

9. Discuss the importance of good communication and teamwork in complex bonding projects?

- Effective communication ensures a clear understanding of project goals, requirements, and challenges.

- Teamwork fosters collaboration, information sharing, and problem-solving.

- Open communication channels promote early identification and resolution of issues, leading to successful project outcomes.

10. How do you stay up-to-date on the latest bonding technologies and industry best practices?

- Attending industry conferences and workshops.

- Reading technical publications and industry journals.

- Participating in professional development courses and certifications.

- Networking with other bonding professionals and experts.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Bonder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Bonder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Bonders are responsible for joining and bonding materials, primarily using adhesives and bonding agents. Their key job responsibilities typically include:

1. Preparing Surfaces

Ensuring that bonding surfaces are clean, smooth, and free of any contaminants or defects that may affect adhesion.

2. Selecting and Applying Adhesives

Choosing the appropriate adhesive for the materials and bonding requirements, and applying it accurately and evenly, following specified procedures and safety guidelines.

3. Bonding Materials

Using bonding equipment or tools to join materials, applying pressure or heat as required, and ensuring that the bond achieves the desired strength and durability.

4. Finishing and Inspecting Joints

Smoothing, trimming, or finishing bonded joints as necessary to ensure proper aesthetics and functionality, and inspecting joints to verify their quality and adherence to specifications.

5. Quality Control

Maintaining quality standards by following established bonding procedures, adhering to safety regulations, and monitoring the performance of bonded products.

Interview Tips

Preparing for a job interview as a Bonder requires effective strategies and a thorough understanding of the role. Here are some tips to help you ace your interview:

1. Research the Company and Role

Familiarize yourself with the company’s history, mission, and products or services. Examine the specific requirements and expectations of the Bonder position you’re applying for.

2. Highlight Relevant Skills and Experience

Emphasize your skills in surface preparation, adhesive selection, bonding techniques, and quality control. If possible, quantify your accomplishments using specific metrics, such as the number of bonded components produced or the percentage of defective joints reduced.

3. Demonstrate Attention to Detail

Bonding requires precision and meticulous attention to detail. During the interview, highlight your ability to work accurately, follow instructions precisely, and ensure that bonded joints meet the required specifications.

4. Show Understanding of Safety Procedures

Bonding processes often involve the use of adhesives and equipment that require proper handling. Emphasize your knowledge of safety regulations and your commitment to adhering to them to ensure a safe work environment.

5. Prepare Examples of Your Work

If possible, provide examples or portfolio pieces that showcase your bonding skills and abilities. This could include photographs of bonded joints or documentation of quality control processes you have implemented.

6. Practice Common Interview Questions

Research common interview questions related to bonding, such as “Describe your process for preparing surfaces for bonding” or “How do you ensure the strength and durability of bonded joints?” Practice answering these questions clearly and concisely, highlighting your expertise.

7. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally and arrive for your interview on time. This demonstrates respect for the interviewer and the company, and sets a positive tone for the conversation.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Bonder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!