Feeling lost in a sea of interview questions? Landed that dream interview for Breaker Machine Tender but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Breaker Machine Tender interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

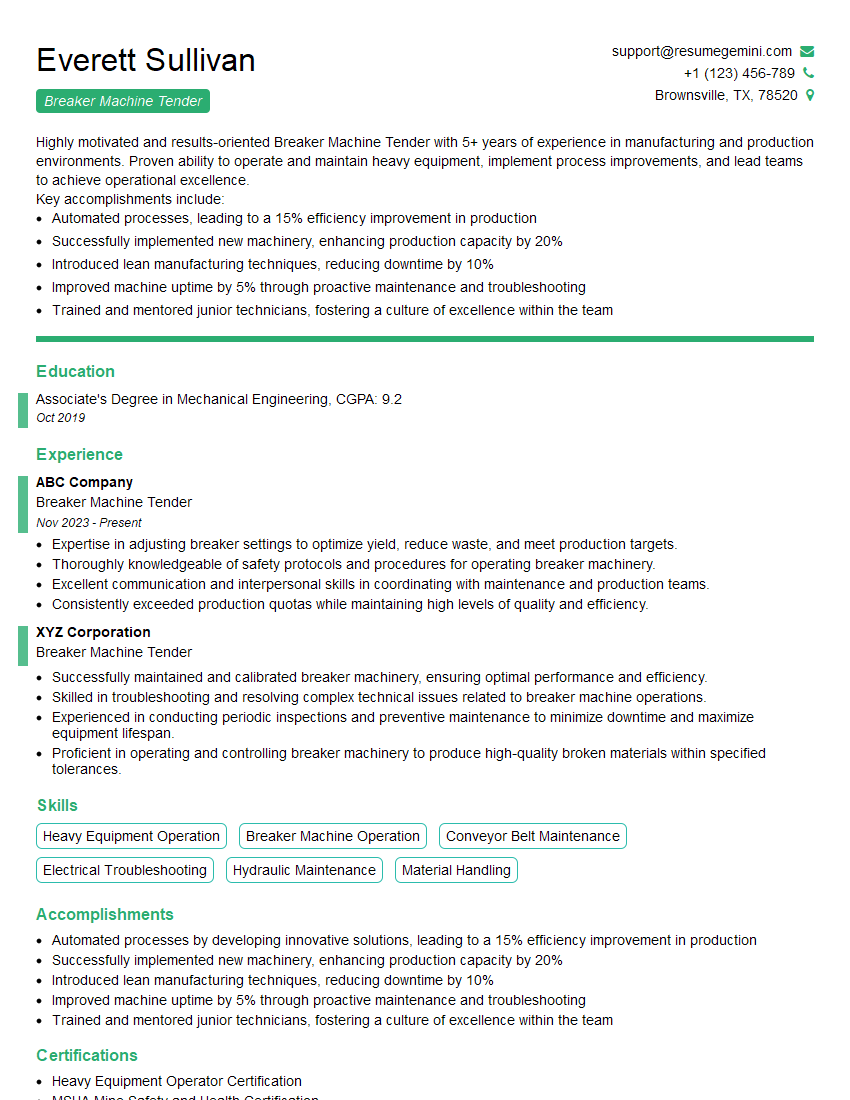

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Breaker Machine Tender

1. What are the key responsibilities of a Breaker Machine Tender?

As a Breaker Machine Tender, my primary responsibilities revolve around operating and maintaining a breaker machine used to crush and reduce materials.

- Setting up, calibrating, and operating the breaker machine to achieve desired particle size and output.

- Monitoring the machine’s performance, adjusting settings, and troubleshooting any issues promptly.

2. Describe the different types of materials that can be processed using a breaker machine.

Types of materials

- Ores and minerals (e.g., limestone, granite, iron ore)

- Construction materials (e.g., concrete, asphalt, bricks)

- Industrial and chemical products (e.g., polymers, pigments)

Factors influencing choice of material

- Hardness and brittleness

- Size and shape

- Desired particle size and output

3. Explain the safety protocols and procedures involved in operating a breaker machine.

Safety is paramount when operating a breaker machine. I strictly adhere to established protocols and procedures:

- Wearing appropriate personal protective equipment (PPE), including gloves, safety glasses, and hearing protection.

- Inspecting the machine thoroughly before each use and reporting any defects.

- Following lockout/tagout procedures to isolate the machine from power during maintenance or repairs.

- Maintaining a clean and organized work area to minimize tripping hazards and prevent dust accumulation.

4. How do you ensure the efficiency and productivity of the breaker machine?

To optimize efficiency and productivity:

- I regularly inspect and calibrate the machine to maintain optimal performance.

- I adjust settings based on the material being processed and desired output.

- I monitor throughput and make adjustments as needed to maximize output while maintaining quality.

- I perform preventive maintenance, including lubrication, cleaning, and minor repairs, to prevent breakdowns and extend the machine’s lifespan.

5. What quality control measures do you implement to ensure the processed materials meet specifications?

Quality control is crucial:

- I visually inspect the processed materials to ensure they meet the desired particle size and consistency.

- I conduct sieve analysis or other testing methods to verify that the materials meet the required specifications.

- I maintain records and documentation to track the quality of the processed materials and identify any deviations.

- I communicate any quality issues promptly to the supervisor or quality control department for corrective action.

6. Describe the maintenance procedures you perform on the breaker machine.

Regular maintenance is essential for optimal performance:

- Lubrication of moving parts to reduce friction and wear.

- Cleaning of the machine, including removing dust and debris to prevent blockages and ensure proper operation.

- Inspection of belts, chains, and other components for wear or damage and replacing them as needed.

- Calibration of the machine to maintain accuracy and consistency of the processed materials.

7. How do you troubleshoot and resolve common problems with the breaker machine?

Troubleshooting is crucial to minimize downtime:

- I identify the problem by observing the machine’s behavior, checking error codes, and conducting diagnostic tests.

- I consult the manufacturer’s manuals and technical resources to determine the root cause of the issue.

- I perform the necessary repairs or adjustments to resolve the problem and restore the machine’s functionality.

- I document the troubleshooting process and any repairs made for future reference and improvement.

8. What are some innovative techniques or improvements you have implemented in your role as a Breaker Machine Tender?

I am always looking for ways to improve efficiency and quality:

- I developed a system for monitoring the machine’s performance data and identifying areas for optimization.

- I implemented a predictive maintenance program to proactively identify potential issues and schedule maintenance before they become problems.

- I collaborated with engineers to design and implement modifications to the machine that improved its output capacity and reduced maintenance time.

9. How do you stay updated with the latest industry trends and advancements related to breaker machine technology?

Continuous learning is essential:

- I attend industry conferences and seminars to learn about new technologies and best practices.

- I read technical journals and articles to stay informed about the latest developments in the field.

- I participate in online forums and discussions to exchange knowledge and ideas with other professionals.

10. How do you plan and prioritize your workload to meet production targets while ensuring quality?

Effective planning and prioritization are key:

- I develop a daily work schedule and prioritize tasks based on their urgency and impact on production.

- I allocate sufficient time for quality control checks and inspections to ensure that the processed materials meet specifications.

- I communicate with the supervisor and other team members to coordinate tasks and ensure that all activities are aligned with production goals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Breaker Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Breaker Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

## Key Job Responsibilities: – Monitor and adjust breaker machine settings to ensure optimal performance. – Inspect materials and ensure they meet specifications. – Perform maintenance and repairs on breaker machine components, such as hammers, blades, and screens. – Assist with installation and relocation of breaker machine. – Maintain a clean and safe work area. – Collaborate with production team to identify and resolve issues. – Comply with safety regulations and wear personal protective equipment. ## Interview Preparation Tips: 1. Research the Company: – Visit the company website to learn about its mission, values, and products/services. – Read industry publications and articles to stay informed about the company’s industry. 2. Review Job Description: – Thoroughly read the job description to understand the key responsibilities, qualifications, and company culture. – Identify specific skills and experiences that match the job requirements. 3. Practice Behavioral Interview Questions: – Prepare for questions that explore your past experiences and behaviors. – Use the STAR method (Situation, Task, Action, Result) when answering to provide specific and detailed examples. – Examples: – Describe a time you resolved a complex issue with a breaker machine. – Explain how you have maintained a safe and efficient work environment. 4. Prepare Industry-Specific Questions: – Research the latest industry trends and technologies related to breaker machines. – Prepare questions to ask the interviewer about the company’s equipment, processes, and advancements. 5. Showcase Your Skills: – Highlight your technical skills in operating and maintaining breaker machines. – Emphasize your ability to troubleshoot and resolve issues. – Provide examples of your attention to detail and safety consciousness. – Demonstrate your communication and teamwork abilities. 6. Be Enthusiastic and Confident: – Convey your passion for the industry and the role. – Show your confidence in your abilities and willingness to learn. – Maintain eye contact and speak clearly and concisely. 7. Follow Up: – After the interview, send a thank-you note to the interviewer within 24 hours. – Reiterate your interest in the position and express your appreciation for their time.Next Step:

Now that you’re armed with the knowledge of Breaker Machine Tender interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Breaker Machine Tender positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini