Are you gearing up for an interview for a Brush Fabrication Supervisor position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Brush Fabrication Supervisor and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

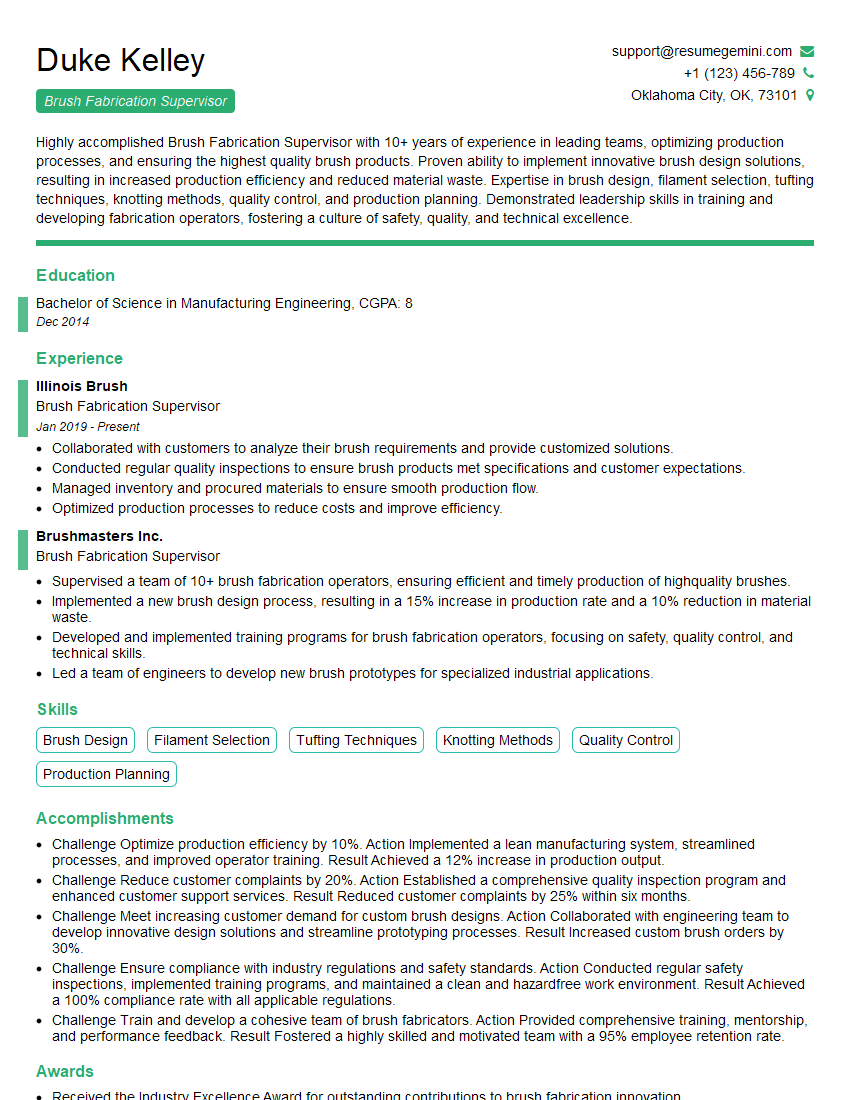

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Brush Fabrication Supervisor

1. Describe the process of brush fabrication, highlighting key steps and quality control measures.

Key Steps:

- Filament selection and preparation

- Hole-punching and tufting

- Adhesive application and curing

- Trimming and finishing

Quality Control Measures:

- Visual inspection for filament integrity and tuft density

- Tensile testing for filament strength

- Adhesion testing to ensure proper bond strength

- Dimensional verification for accuracy

2. Explain the different types of filaments used in brush fabrication and their specific applications.

Natural Filaments:

- Horsehair: Durable, stiff, and resistant to chemicals

- Hog hair: Soft, absorbent, and often used in paintbrushes

Synthetic Filaments:

- Nylon: Strong, flexible, and resistant to abrasion

- Polyester: Chemical-resistant, retains shape well, and suitable for high-temperature applications

Specialty Filaments:

- Abrasive filament: For abrasive applications like cleaning and polishing

- Conductive filament: For brushes used in electronics

3. What are the common adhesion methods used in brush fabrication and how do they affect the overall performance of the brush?

Common Adhesion Methods:

- Epoxy adhesives: Strong, durable, and suitable for harsh environments

- Cyanoacrylate adhesives (superglue): Fast-acting, but not as durable as epoxy

- Hot melt adhesives: Provide instant bonding, but can be messy

Impact on Performance:

- Adhesive strength affects the brush’s overall durability and ability to retain filaments

- Adhesive flexibility influences the brush’s flexibility and resistance to bending

- Adhesive resistance to chemicals and heat ensures the brush’s performance in demanding environments

4. Describe the role of brush density in determining the performance of a brush.

- Higher density: Creates a more rigid brush with increased stiffness and abrasive action

- Lower density: Results in a softer brush with less stiffness and more flexibility

- Density optimization: Different brush applications require specific densities to achieve optimal results

5. Explain the importance of trim length and profile in brush design.

Trim Length:

- Affects the brush’s stiffness and ability to penetrate surfaces

- Longer trim length provides increased flexibility and reach

Trim Profile:

- Determines the shape and angle of the brush’s bristles

- Flat trim: General-purpose brushes

- Tapered trim: Conical shape for better penetration

6. What are the key factors to consider when selecting brush materials for a specific application?

- Filament properties (stiffness, flexibility, chemical resistance)

- Adhesion strength and durability

- Brush density and trim length

- Environmental conditions (temperature, humidity, chemicals)

- Application requirements (cleaning, polishing, abrading)

7. Describe the different techniques used to test the quality of a brush and ensure that it meets specifications.

Visual Inspection:

- Filament integrity

- Tuft density

- Trim length and profile

Mechanical Testing:

- Tensile testing for filament strength

- Adhesion testing for bond strength

- Flexibility testing for brush stiffness

Performance Evaluation:

- Actual application testing in the intended environment

- Measurement of cleaning or scrubbing efficiency

8. Explain the importance of brush maintenance and how it affects the performance and longevity of the brush.

- Regular cleaning to remove debris and prevent filament damage

- Proper storage in a dry and temperature-controlled environment

- Replacement of worn or damaged filaments

- Scheduled maintenance to ensure optimal performance and extend brush life

9. What are the latest advancements in brush fabrication technology and how do they benefit the industry?

Automated Fabrication:

- Increased production efficiency and consistency

Advanced Filament Materials:

- Improved durability, flexibility, and chemical resistance

3D Printing:

- Custom brush designs and complex shapes

Sustainability:

- Use of biodegradable and recyclable materials

10. As a Brush Fabrication Supervisor, how would you implement quality control measures and ensure continuous improvement in the production process?

Quality Control Measures:

- Establish clear quality standards and inspection procedures

- Implement regular quality checks throughout the fabrication process

Continuous Improvement:

- Monitor production data and identify areas for improvement

- Encourage employee feedback and suggestions

- Implement lean manufacturing principles to reduce waste and inefficiencies

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Brush Fabrication Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Brush Fabrication Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Brush Fabrication Supervisor is responsible for overseeing the production of brushes, ensuring that they meet quality standards and are produced efficiently.

1. Manage Production Process

The supervisor ensures that all stages of the production process are running smoothly, from raw material procurement to finished product packaging.

- Plan and schedule production

- Monitor production progress

- Identify and resolve production issues

2. Quality Control

The supervisor is responsible for ensuring that all brushes produced meet the required quality standards.

- Develop and implement quality control procedures

- Inspect raw materials and finished products

- Investigate and resolve quality issues

3. Team Management

The supervisor leads and manages a team of brush makers and other staff.

- Hire, train, and develop staff

- Motivate and lead the team

- Resolve employee issues

4. Continuous Improvement

The supervisor is responsible for continuously improving the production process and the quality of the brushes produced.

- Identify areas for improvement

- Develop and implement improvement plans

- Monitor and evaluate the results of improvement efforts

Interview Tips

To ace your interview for a Brush Fabrication Supervisor position, here are some tips:

1. Research the Company and the Position

Take the time to learn about the company’s history, products, and culture.

- Visit the company’s website and social media pages.

- Read industry news and articles.

- Talk to people who work for the company.

2. Practice Answering Common Interview Questions

There are certain questions that are commonly asked in interviews for Brush Fabrication Supervisor positions.

- Tell me about your experience in brush fabrication.

- What are your strengths and weaknesses as a supervisor?

- How do you ensure the quality of the brushes you produce?

- What are your goals for this position?

3. Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience in brush fabrication and supervision.

- Highlight your skills and accomplishments.

- Use specific examples to demonstrate your abilities.

- Be prepared to talk about your experience with different types of brushes and production processes.

4. Be Yourself

The interviewer will be able to tell if you’re being genuine, so be yourself and let your personality shine through.

- Don’t try to be someone you’re not.

- Be confident in your abilities.

- Show the interviewer that you’re passionate about brush fabrication.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Brush Fabrication Supervisor, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Brush Fabrication Supervisor positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.