Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cambering Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

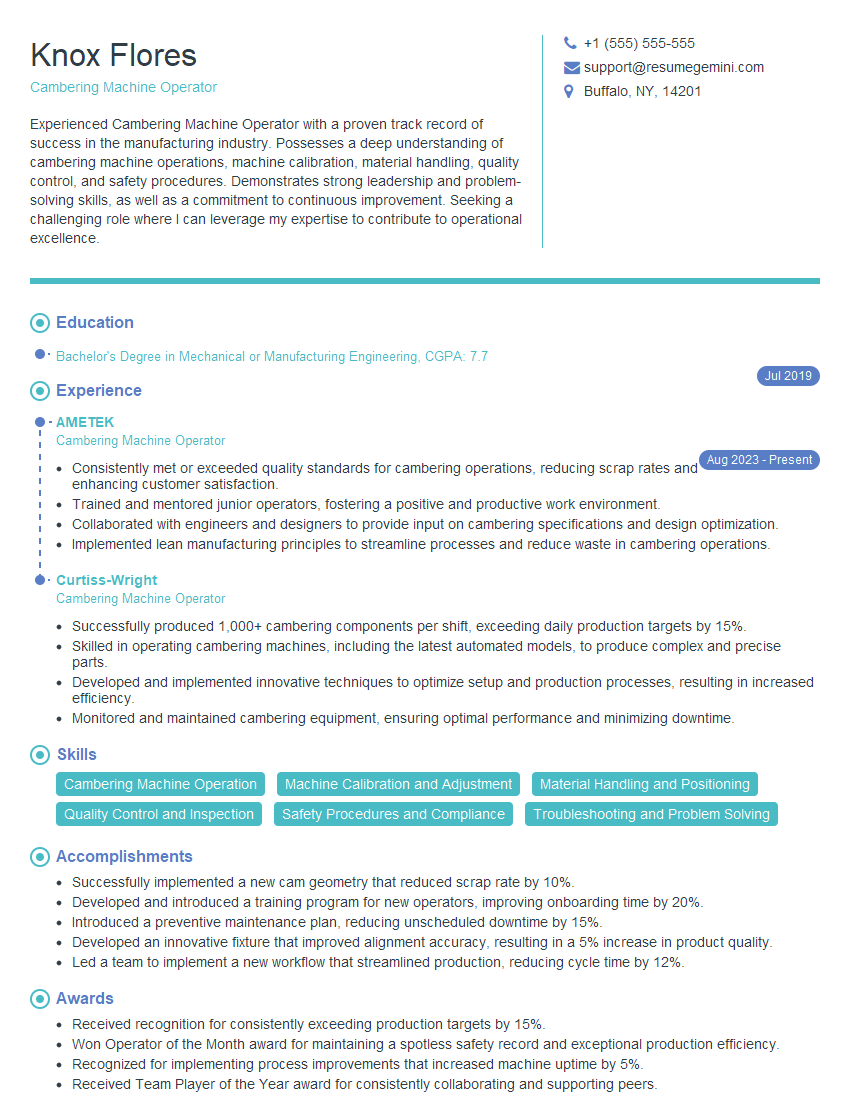

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cambering Machine Operator

1. Explain the process of cambering a machine.

Cambering involves adjusting the angle of the machine’s wheels to ensure proper contact with the ground. Here’s the process:

- Inspect the machine for any signs of misalignment or uneven tire wear.

- Use a specialized camber gauge to measure the current camber angle.

- Adjust the camber bolts or shims to alter the angle according to the manufacturer’s specifications.

- Re-measure the camber angle to verify the adjustment and ensure it meets the desired value.

- Tighten all fasteners securely and test-drive the machine to evaluate the results.

2. Describe the different types of cambering machines.

Manual Cambering Machines

- Require manual adjustments using wrenches or levers.

- Less expensive and easier to operate than automated machines.

Automated Cambering Machines

- Use computer-controlled systems for precise and efficient adjustments.

- Provide faster and more accurate results compared to manual machines.

3. What are the key factors to consider when selecting a cambering machine?

- Type of machines: manual or automated.

- Capacity: maximum weight and size of machines it can handle.

- Accuracy: precision of the measurements and adjustments.

- Ease of use: user-friendliness and training requirements.

- Cost: initial purchase price and ongoing maintenance expenses.

4. How do you troubleshoot common cambering problems?

- Uneven tire wear: Inspect for incorrect camber settings, misaligned suspension components, or damaged tires.

- Poor handling: Check for excessive positive or negative camber, which can affect stability and steering.

- Excessive vibration: Verify that the camber settings are within specifications and inspect for imbalances in tires or wheels.

5. Explain the importance of proper camber settings.

- Optimizes tire contact with the road surface, improving traction and handling.

- Reduces uneven tire wear, extending tire life and saving on replacement costs.

- Enhances vehicle stability and responsiveness, providing a smoother and safer ride.

6. Describe the safety precautions that should be taken when using a cambering machine.

- Wear appropriate safety gear, including gloves and eye protection.

- Ensure that the machine is properly grounded and stable before operation.

- Lift the machine only at designated lifting points.

- Do not operate the machine if it shows signs of damage or malfunction.

- Follow the manufacturer’s instructions and safety guidelines.

7. What are the different types of camber gauges?

Bubble Camber Gauges

- Use a spirit level to indicate the camber angle.

- Simple and affordable, but less precise than other types.

Digital Camber Gauges

- Provide accurate and quick readings using an electronic display.

- Easier to use and more precise than bubble gauges.

Laser Camber Gauges

- Utilize lasers to project a reference line on the tire.

- Highly accurate and can measure camber on both lifted and unlifted wheels.

8. Explain the process of aligning a machine using a cambering machine.

- Place the machine on the cambering machine’s platform.

- Adjust the machine’s wheels to the desired camber angle using the camber bolts or shims.

- Use a camber gauge to measure the camber angle and ensure it meets the specifications.

- Repeat the process for all wheels to achieve the desired alignment.

9. What are the common causes of incorrect camber settings?

- Wear and tear on suspension components.

- Accidents or impact damage.

- Improper alignment during previous maintenance.

- Manufacturing defects.

10. How do you maintain a cambering machine to ensure its accuracy?

- Regularly calibrate the machine using a known reference angle.

- Inspect and clean the sensors and other components regularly.

- Follow the manufacturer’s recommended maintenance schedule.

- Train operators on proper usage and maintenance techniques.

- Keep a maintenance log to track calibrations, repairs, and any potential issues.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cambering Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cambering Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cambering Machine Operators are responsible for operating and maintaining cambering machines, which are used to shape and camber metal sheets and plates. They also ensure that the machines are running smoothly and efficiently.

1. Operate Cambering Machines

Cambering Machine Operators are responsible for operating cambering machines to shape and camber metal sheets and plates. They must be able to set up and calibrate the machines, as well as load and unload the metal sheets and plates. They must also be able to monitor the machines during operation and make adjustments as needed.

- Set up and calibrate cambering machines

- Load and unload metal sheets and plates

- Monitor cambering machines during operation

- Make adjustments to cambering machines as needed

2. Maintain Cambering Machines

Cambering Machine Operators are also responsible for maintaining cambering machines. They must be able to perform routine maintenance tasks, such as cleaning and lubricating the machines. They must also be able to troubleshoot and repair minor problems. They must also be able to order and install replacement parts as needed.

- Clean and lubricate cambering machines

- Troubleshoot and repair minor problems

- Order and install replacement parts

3. Ensure Quality of Cambered Products

Cambering Machine Operators are responsible for ensuring the quality of cambered products. They must be able to inspect cambered products for defects, such as cracks, dents, and scratches. They must also be able to measure the camber of cambered products to ensure that they meet specifications.

- Inspect cambered products for defects

- Measure the camber of cambered products

- Reject cambered products that do not meet specifications

4. Follow Safety Procedures

Cambering Machine Operators must be able to follow safety procedures when operating and maintaining cambering machines. They must be able to wear appropriate safety gear, such as safety glasses and gloves. They must also be able to follow lockout/tagout procedures when performing maintenance on cambering machines.

- Wear appropriate safety gear

- Follow lockout/tagout procedures

- Report any safety hazards

Interview Tips

Preparing for your Cambering Machine Operator interview is key to success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before your interview, take the time to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the position. You can find information about the company on their website, social media pages, and Glassdoor.

- Visit the company’s website

- Read the company’s social media pages

- Read reviews of the company on Glassdoor

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Tell me about yourself

- Why are you interested in this position?

- What are your strengths and weaknesses?

- What is your salary expectation?

3. Be Prepared to Talk About Your Experience

The interviewer will likely want to know about your experience operating and maintaining cambering machines. Be prepared to discuss your experience in detail, including the specific tasks you performed. You should also be prepared to talk about any challenges you faced and how you overcame them.

- Describe your experience operating cambering machines

- Discuss the specific tasks you performed

- Talk about any challenges you faced and how you overcame them

4. Ask Questions

At the end of the interview, the interviewer will likely give you an opportunity to ask questions. This is your chance to learn more about the position and the company. It is also a good opportunity to show the interviewer that you are interested in the position and that you have done your research.

- What are the biggest challenges facing the company right now?

- What is the company’s culture like?

- What are the opportunities for advancement?

Next Step:

Now that you’re armed with the knowledge of Cambering Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Cambering Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini