Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Cartridge Gauger interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Cartridge Gauger so you can tailor your answers to impress potential employers.

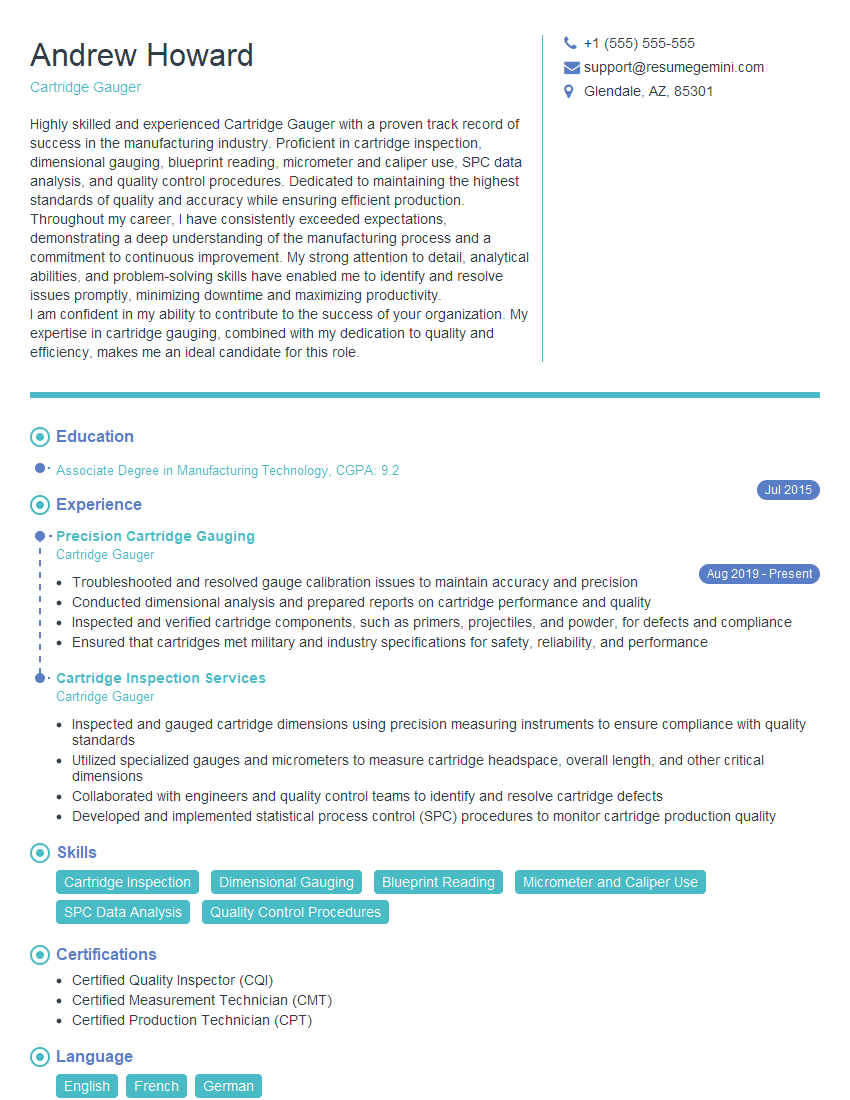

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cartridge Gauger

1. Explain the process of cartridge gauging and its significance in quality control?

Cartridge gauging is a critical quality control process in the manufacturing of ammunition. It involves using specialized gauges to verify the dimensions, tolerances, and other characteristics of cartridge cases, bullets, and primers to ensure they meet the required specifications.

- Ensuring Consistent Ammunition Performance: Cartridge gauging helps guarantee that cartridges function correctly and safely in firearms by verifying their dimensions and tolerances are within the specified limits.

- Defect Detection: Gauges can identify defects such as cracks, burrs, or dimensional deviations that may affect cartridge performance or safety.

- Batch Verification: Gauging allows manufacturers to verify the quality of entire batches of cartridges, ensuring that they meet the desired specifications.

- Regulatory Compliance: Cartridge gauging is often required by industry standards and regulations to demonstrate the quality and safety of ammunition.

2. What are the different types of cartridge gauges and what are their uses?

Gauge Design

- Plug Gauges: Used to check the internal dimensions of cartridge cases, such as the case length, neck diameter, and base diameter.

- Ring Gauges: Used to verify the external diameters of cartridges, such as the bullet diameter, case head diameter, and overall cartridge length.

Gauge Purpose

- Go Gauges: Used to ensure that cartridges will fit properly into firearms.

- No-Go Gauges: Used to identify cartridges that are too large or oversized to prevent chambering or firing issues.

- Functional Gauges: Used to test the overall functionality of cartridges in firearms, including extraction, ejection, and feeding.

3. How do you calibrate and maintain cartridge gauges?

Cartridge gauges must be regularly calibrated and maintained to ensure their accuracy and reliability.

- Calibration: Gauges are calibrated using certified master gauges or reference standards to verify their dimensions and tolerances.

- Cleaning: Gauges should be cleaned regularly to remove any dirt, debris, or contaminants that may affect their precision.

- Inspection: Gauges should be inspected visually for any signs of wear, damage, or corrosion. Any defective gauges should be removed from service.

- Documentation: Calibration and maintenance records should be kept to track gauge performance and ensure traceability.

4. What are the safety precautions you observe when working with cartridge gauges?

Cartridge gauges are used with live ammunition, so it’s crucial to follow proper safety protocols:

- Wear appropriate safety gear: Safety glasses, gloves, and hearing protection should be worn.

- Handle ammunition carefully: Always use proper handling techniques and avoid touching live primers or cartridges.

- Keep the work area clean: Cartridge cases, bullets, or other debris can create trip or slip hazards.

- Follow established procedures: Always adhere to documented operating procedures and safety guidelines.

- Never force a gauge: If a cartridge does not fit into a gauge smoothly, do not force it. This could indicate a problem with the cartridge or the gauge.

5. How do you interpret the results of cartridge gauging and determine if a cartridge is acceptable?

After gauging a cartridge, the results should be compared to the specified tolerance limits:

- Go Gauge: If the cartridge passes through the Go gauge without significant resistance, it is considered acceptable for use.

- No-Go Gauge: If the cartridge does not fully enter the No-Go gauge, it exceeds the maximum allowable dimensions and should be rejected.

- Other Gauges: Depending on the specific requirements, other gauges may be used to check additional dimensions or functional aspects of the cartridge.

6. How do you troubleshoot common problems encountered during cartridge gauging?

- Cartridge Does Not Fit Gauge: This could indicate a problem with the cartridge dimensions, the gauge, or both. The gauge should be inspected for damage or wear, and the cartridge should be re-measured using a different gauge or a reference standard.

- Gauge Sticks in Cartridge: This could be caused by contaminants on the gauge or cartridge, or by excessive wear on the gauge. The gauge should be cleaned and inspected, and the cartridge should be re-gauged.

- Gauge Results Inconsistent: If the gauging results vary significantly between different gauges or operators, it may indicate a problem with the gauges or the gauging process. The gauges should be calibrated and the gauging procedure should be reviewed and standardized.

7. What are the different industry standards and regulations that apply to cartridge gauging?

- SAAMI (Sporting Arms and Ammunition Manufacturers’ Institute): SAAMI establishes standards for cartridge dimensions, tolerances, and testing procedures.

- CIP (Commission Internationale Permanente pour l’Epreuve des Armes à Feu Portatives): CIP sets standards for firearms and ammunition in Europe.

- ASTM (American Society for Testing and Materials): ASTM publishes standards for gauging and testing of materials, including ammunition components.

- ISO (International Organization for Standardization): ISO develops standards for a wide range of industries, including ammunition and gauging.

8. How do you stay updated on the latest advancements in cartridge gauging technology and best practices?

- Attend industry conferences and workshops: These events provide opportunities to learn about new technologies and connect with experts in the field.

- Read industry publications: Magazines and journals dedicated to ammunition manufacturing and testing can provide valuable information on gauging techniques and advancements.

- Network with other cartridge gaugers: Joining professional organizations or online forums allows for sharing of knowledge and experiences.

- Consult with manufacturers: Equipment manufacturers often provide technical support and updates on their gauging products and technologies.

9. Describe a situation where you encountered a challenging cartridge gauging problem and how you resolved it.

In one instance, we were gauging a batch of rifle cartridges and encountered a high rejection rate. The cartridges were failing the No-Go gauge, indicating they were oversized. After careful inspection, we discovered that the cartridge cases had been improperly annealed, resulting in softer brass that was expanding excessively during the gauging process. We adjusted the annealing process to ensure proper hardness and successfully resolved the issue.

10. What are your long-term career goals in the field of cartridge gauging?

My long-term goal is to advance my expertise and contribute to the continuous improvement of cartridge gauging practices. I aspire to become a recognized expert in the field, stay abreast of the latest technologies, and share my knowledge through training and mentorship. Additionally, I am interested in exploring the development of innovative gauging techniques and equipment to enhance the accuracy and efficiency of ammunition quality control.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cartridge Gauger.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cartridge Gauger‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Cartridge Gauger is responsible for ensuring that cartridges meet specified dimensions and quality standards. Their primary duties involve using precision measuring tools and gauges to inspect and measure cartridge components and assemblies.

1. Inspection and Measurement

Cartridge Gaugers meticulously inspect and measure cartridge components, including cases, projectiles, primers, and powder charges. They utilize calipers, micrometers, and other specialized gauges to verify conformance to established tolerances and specifications.

- Inspect cartridge cases for proper dimensions, including length, diameter, and headspace.

- Measure projectile diameters, weights, and lengths to ensure compliance with specifications.

- Verify primer seating depth and orientation.

2. Quality Control

Cartridge Gaugers play a vital role in maintaining product quality. They identify and report any defects or deviations from specifications.

- Identify and document non-conforming cartridges.

- Participate in quality control procedures and process improvement initiatives.

3. Equipment Maintenance and Calibration

Cartridge Gaugers are responsible for maintaining and calibrating measuring tools and equipment used for inspection.

- Perform routine maintenance on gauges and calipers.

- Calibrate equipment regularly to ensure accuracy and precision.

- Maintain records of equipment maintenance and calibration.

4. Documentation and Reporting

Cartridge Gaugers document and report inspection results and quality control findings.

- Prepare inspection reports and maintain records of measurements.

- Report any quality issues or discrepancies to supervisors.

Interview Tips

To ace an interview for a Cartridge Gauger position, candidates should prepare thoroughly and demonstrate their skills and knowledge.

1. Research the Industry and Company

Research the ammunition industry, firearm manufacturing processes, and the specific company you’re applying to. Familiarity with their products, quality standards, and business practices will impress the interviewer.

- Review industry publications and websites.

- Visit the company website to learn about their products and services.

- Check social media channels for company news and updates.

2. Highlight Relevant Skills and Experience

Emphasize your experience in using precision measuring tools and gauges. Highlight your ability to interpret specifications, identify defects, and maintain quality standards.

- Quantify your accomplishments with specific examples.

- Explain how your experience has developed your attention to detail and analytical abilities.

3. Demonstrate Quality Consciousness

Convey your understanding of the importance of quality control in ammunition manufacturing. Explain how your work ensures the safety and reliability of cartridges.

- Describe your knowledge of quality control principles and best practices.

- Share examples of how you have contributed to improving product quality.

4. Practice Common Interview Questions

Prepare answers to common interview questions related to your skills, experience, and career goals. Practice your responses to ensure clarity and conciseness.

- Tell me about your experience in using precision measuring tools.

- How do you ensure the accuracy of your measurements?

- Describe a time when you identified a quality issue.

Next Step:

Now that you’re armed with the knowledge of Cartridge Gauger interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Cartridge Gauger positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini