Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Casting and Curing Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

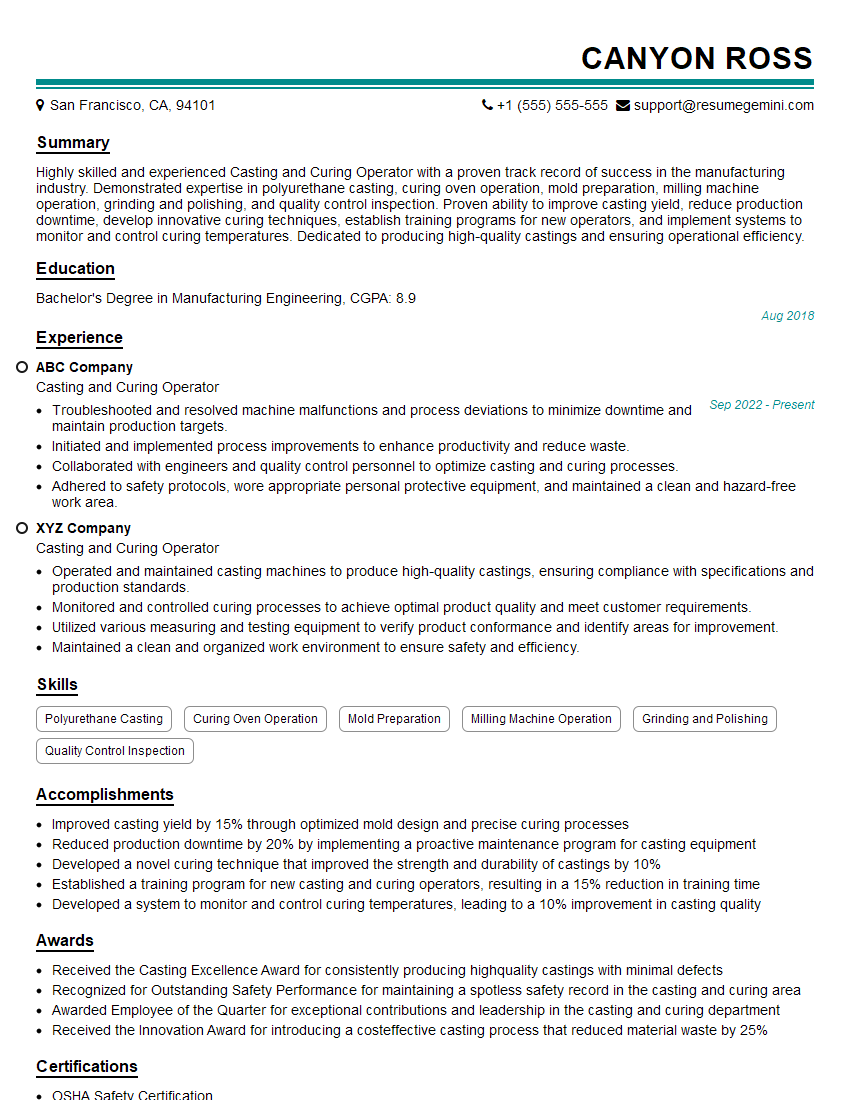

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Casting and Curing Operator

1. Describe the process of casting and curing concrete products?

answer here

- Prepare the molds by cleaning and applying a release agent.

- Mix the concrete according to the manufacturer’s instructions.

- Pour the concrete into the molds and vibrate to remove air bubbles.

- Allow the concrete to cure for a period of time, typically 24 hours.

- Remove the concrete products from the molds and place them in a curing chamber.

- Monitor the temperature and humidity in the curing chamber to ensure proper curing.

2. What are the different types of concrete casting methods?

Gravity casting

- Concrete is poured into the mold and allowed to flow under gravity.

- This method is suitable for simple shapes and small castings.

Pressure casting

- Concrete is forced into the mold under pressure.

- This method is used for complex shapes and large castings.

Vacuum casting

- Air is removed from the mold before the concrete is poured.

- This method is used to produce castings with a smooth surface finish.

3. What are the common defects that can occur in concrete castings?

answer here

- Voids

- Cracks

- Honeycombing

- Efflorescence

- Spalling

4. How can you prevent defects in concrete castings?

answer here

- Use properly mixed concrete.

- Use the correct casting method for the shape and size of the casting.

- Cure the concrete properly.

- Use a release agent to prevent the concrete from sticking to the mold.

5. What are the different types of curing methods for concrete?

answer here

- Water curing

- Steam curing

- Heat curing

- Chemical curing

6. What are the factors that affect the strength of concrete?

answer here

- Water-cement ratio

- Type of cement

- Aggregate size and shape

- Curing conditions

7. What are the different types of concrete additives?

answer here

- Air-entraining agents

- Water-reducing agents

- Accelerators

- Retarders

8. What are the safety precautions that should be taken when working with concrete?

answer here

- Wear protective clothing, including gloves, goggles, and a respirator.

- Keep the work area well-ventilated.

- Do not smoke or eat in the work area.

- Be aware of the hazards of wet concrete, which can cause burns and other injuries.

9. What are the different types of concrete finishing techniques?

answer here

- Troweling

- Floating

- Brushing

- Stamping

10. What are the different types of concrete testing methods?

answer here

- Compressive strength test

- Tensile strength test

- Flexural strength test

- Shear strength test

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Casting and Curing Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Casting and Curing Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Casting and Curing Operators play a vital role in the production of high-quality concrete products. Their key responsibilities encompass the following:

1. Casting Process

Operate casting machines to pour concrete mix into molds or forms.

- Ensure proper mix proportions and consistency.

- Monitor casting operations to identify and resolve any issues.

2. Curing Process

Maintain proper curing conditions by controlling temperature and humidity.

- Monitor and adjust curing time and temperature based on product specifications.

- Ensure proper ventilation during curing to prevent defects.

3. Quality Control

Inspect finished products for any defects or imperfections.

- Identify and segregate non-conforming products for rework or disposal.

- Maintain records of quality checks and inspections.

4. Equipment Maintenance

Perform basic maintenance and cleaning of casting and curing equipment.

- Lubricate moving parts, tighten bolts, and clean surfaces.

- Report any equipment malfunctions or issues promptly.

Interview Tips

To ace the interview for the Casting and Curing Operator position, candidates should focus on the following tips:

1. Research the Company and Industry

Gather information about the company’s history, products, and industry trends. This demonstrates interest and knowledge of the field.

- Visit the company website, read industry publications, and connect with employees on LinkedIn.

- Prepare questions about the company and the role to show engagement.

2. Practice Technical Skills

Review the key job responsibilities outlined above and practice describing your experience in casting, curing, and quality control.

- Use specific examples from your work history to illustrate your abilities.

- Prepare to discuss different types of concrete mixes and curing techniques.

3. Highlight Safety and Quality

Emphasize your commitment to safety and quality in the workplace.

- Describe your experience with safety protocols and accident prevention.

- Explain your understanding of quality standards and how you ensure product quality.

4. Showcase Physical Capabilities

The role requires physical stamina and attention to detail. Be prepared to discuss your ability to perform repetitive tasks and work in a physically demanding environment.

- Highlight your physical fitness and endurance.

- Mention any previous experience in physically challenging or labor-intensive roles.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Casting and Curing Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.