Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Casting Plug Assembler interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Casting Plug Assembler so you can tailor your answers to impress potential employers.

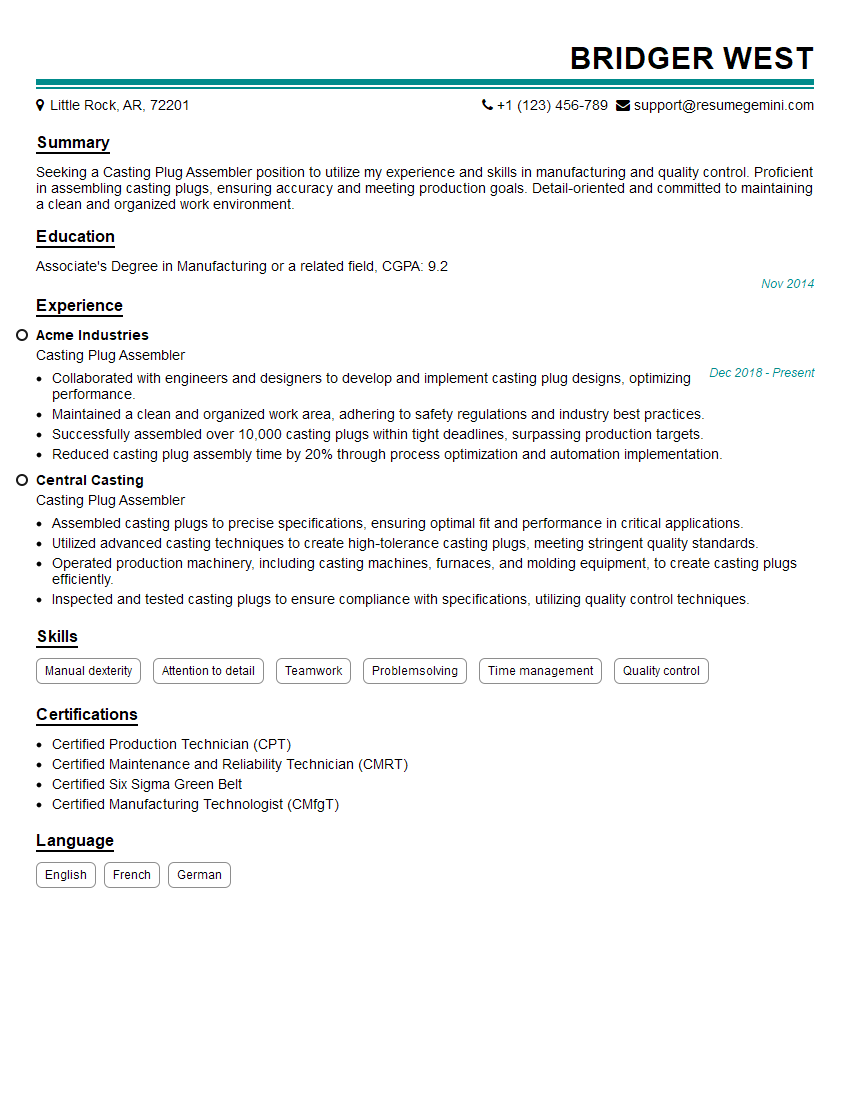

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Casting Plug Assembler

1. How would you ensure the casting plug is assembled correctly?

To ensure the casting plug is assembled correctly, I would adhere to these steps:

- Thoroughly review the assembly instructions and specifications.

- Inspect all components for any defects or inconsistencies.

- Follow the assembly sequence precisely, using the appropriate tools and materials.

- Tighten the fasteners to the specified torque values.

- Conduct a visual inspection to verify proper assembly and alignment.

- Perform functional testing to ensure the casting plug operates as intended.

2. How do you maintain casting plug assembly tools and equipment?

To maintain casting plug assembly tools and equipment:

- Regularly clean and inspect tools to ensure they are free of debris and damage.

- Lubricate moving parts and components as specified in the manufacturer’s instructions.

- Calibrate and maintain measuring and testing instruments to ensure accuracy.

- Follow proper storage procedures to prevent damage and deterioration.

- Report any maintenance issues or equipment malfunctions promptly.

3. What techniques do you use to troubleshoot casting plug assembly issues?

When troubleshooting casting plug assembly issues:

- Identify the specific problem by visually inspecting the assembly and reviewing any error messages.

- Refer to technical documentation and consult with colleagues to gather information about potential causes.

- Methodically test and replace components as necessary to isolate the source of the issue.

- Document the troubleshooting process and implement corrective actions to prevent future occurrences.

- Collaborate with engineers or other experts if necessary to resolve complex problems.

4. How do you meet production targets while maintaining quality standards?

To meet production targets while maintaining quality standards:

- Plan and optimize the assembly process to minimize production time.

- Establish clear work instructions and ensure all personnel are adequately trained.

- Conduct regular quality checks at various stages of the assembly process.

- Implement continuous improvement measures to enhance efficiency and reduce defects.

- Communicate closely with production planning to ensure a steady supply of materials and avoid bottlenecks.

5. How do you prioritize tasks and manage your workload?

To prioritize tasks and manage my workload:

- Create a daily or weekly task list and rank them according to their importance and urgency.

- Allocate time slots for different tasks and stick to the schedule as closely as possible.

- Break down overwhelming tasks into smaller, manageable chunks.

- Delegate tasks to others when appropriate to lighten my load.

- Take regular breaks to avoid burnout and maintain productivity.

6. How do you ensure safety in the casting plug assembly area?

To ensure safety in the casting plug assembly area:

- Wear appropriate personal protective equipment, such as gloves, safety glasses, and earplugs.

- Follow established safety protocols and procedures for handling tools, materials, and equipment.

- Maintain a clean and organized work environment to prevent tripping hazards and other accidents.

- Be aware of potential hazards, such as sharp edges, moving machinery, and electrical risks.

- Report any safety concerns or incidents promptly to a supervisor.

7. What is the purpose of using different types of adhesives in casting plug assembly?

Different types of adhesives are used in casting plug assembly to:

- Bond dissimilar materials together, such as metal and plastic.

- Provide strength and rigidity to the assembly.

- Create a watertight or airtight seal to prevent leaks.

- Reduce vibration and noise.

- Protect components from corrosion or other environmental factors.

8. How do you ensure the quality of incoming raw materials used in casting plug assembly?

To ensure the quality of incoming raw materials:

- Establish clear specifications and tolerances for all materials.

- Inspect and test materials upon receipt to verify conformance to specifications.

- Work with suppliers to develop and maintain quality control measures.

- Maintain proper storage conditions to prevent damage or deterioration.

- Implement a system for tracking and traceability of materials.

9. How do you document and maintain assembly records?

To document and maintain assembly records:

- Create and maintain detailed assembly procedures.

- Record all assembly parameters, such as torque values, adhesive types, and testing results.

- Use a computerized system or manual logbook to store assembly data.

- Provide clear instructions for accessing and reviewing assembly records.

- Implement a system for archiving and retrieving assembly records for future reference.

10. How do you collaborate with other departments within the organization to ensure efficient casting plug assembly?

To collaborate with other departments:

- Establish clear communication channels and regular meetings.

- Share relevant information and updates on project progress.

- Seek input and support from engineers, quality control, and production planning.

- Coordinate efforts to resolve issues and optimize the assembly process.

- Provide feedback and suggestions to improve interdepartmental collaboration.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Casting Plug Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Casting Plug Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Casting Plug Assemblers play a pivotal role in the manufacturing process, ensuring the smooth and efficient assembly of casting plugs. Their key responsibilities include:

1. Casting Plug Assembly

Assembling casting plugs according to specified blueprints and work orders, ensuring accuracy and precision.

2. Quality Control

Inspecting and testing assembled casting plugs to ensure compliance with quality standards, identifying and rectifying any defects.

3. Materials Management

Maintaining an organized and efficient inventory of raw materials and components used in casting plug assembly.

4. Equipment Maintenance

Performing basic maintenance and troubleshooting on assembly equipment, ensuring optimal performance and minimizing downtime.

Interview Tips

To ace the Casting Plug Assembler interview, preparation is key. Here are some effective tips:

1. Research the Company and Position

Thoroughly research the company and the specific role you are applying for. This will demonstrate your interest and enthusiasm, and allow you to ask informed questions during the interview.

2. Highlight Relevant Skills and Experience

In your resume and during the interview, emphasize your relevant skills and experience in casting plug assembly, quality control, and equipment maintenance. Quantify your accomplishments whenever possible to showcase your impact.

3. Practice Common Interview Questions

Prepare for common interview questions by practicing your answers. This will boost your confidence and help you articulate your skills and experience effectively. Consider using the STAR method to answer questions about your past experiences and accomplishments.

4. Ask Thoughtful Questions

At the end of the interview, ask thoughtful questions to demonstrate your engagement and interest in the role. This is an opportunity to clarify any uncertainties, show your eagerness to learn, and leave a lasting impression.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Casting Plug Assembler role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.