Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Cement Contractor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

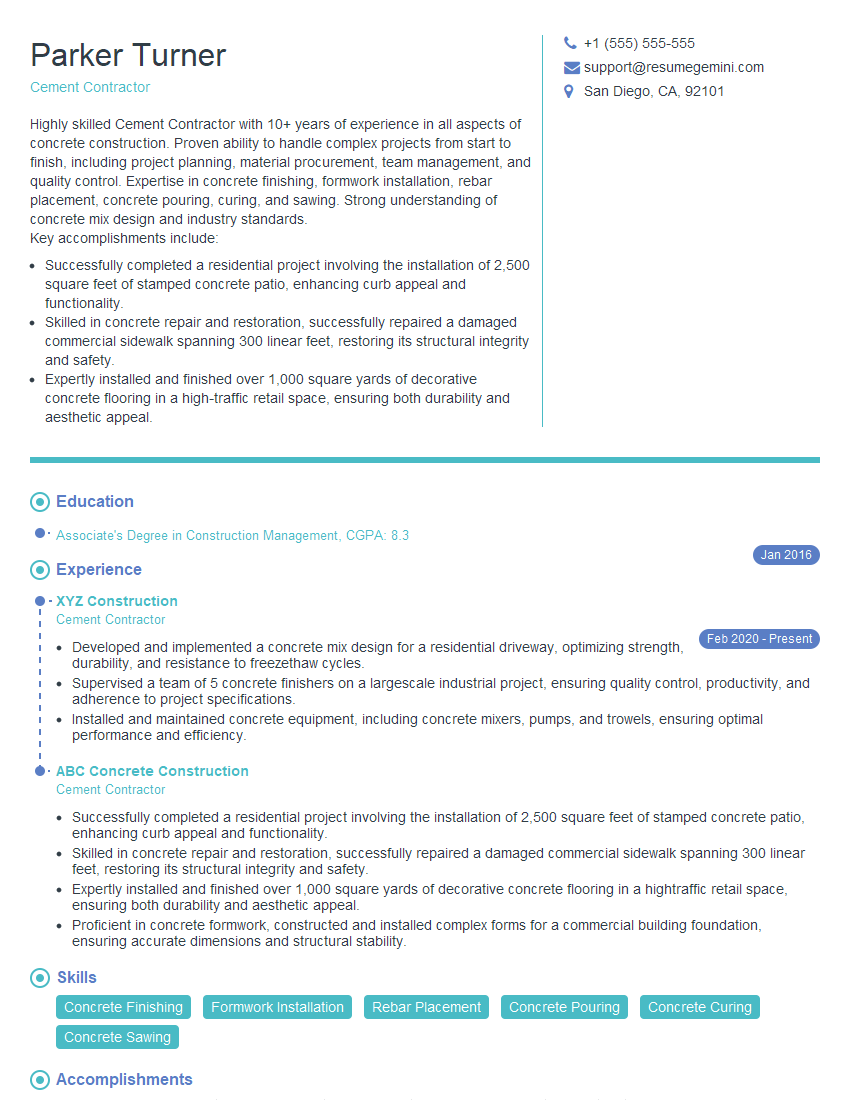

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cement Contractor

1. What are the different types of cement used in construction, and what are their specific applications?

- Portland cement: The most common type of cement, used in a wide variety of applications, including concrete, mortar, and grout.

- Masonry cement: A type of cement that is specifically designed for use in masonry applications, such as bricklaying and mortar.

- Rapid-setting cement: A type of cement that sets quickly, making it ideal for applications where time is of the essence.

- High-strength cement: A type of cement that is designed to produce concrete with high strength, making it ideal for structural applications.

- White cement: A type of cement that is used to produce white concrete, which is often used for aesthetic purposes.

2. What are the key factors to consider when selecting the right cement for a specific project?

Project requirements

- Strength required

- Workability required

- Setting time required

Environmental conditions

- Temperature

- Humidity

- Exposure to chemicals

Availability and cost

3. What are the proper steps for mixing and placing concrete?

- Measure the ingredients: The first step is to measure the correct amount of cement, sand, gravel, and water.

- Mix the ingredients: The ingredients should be mixed together until they are well combined.

- Place the concrete: The concrete should be placed in the forms and tamped down to remove any air pockets.

- Finish the concrete: The concrete should be finished with a trowel or screed to give it a smooth surface.

4. What are the most common problems that can occur when working with cement, and how can they be avoided?

- Cracking: Cracking can be caused by a number of factors, including poor mixing, improper placement, or exposure to extreme temperatures.

- Spalling: Spalling is a condition in which the surface of the concrete breaks away. It can be caused by a number of factors, including poor mixing, improper placement, or exposure to chemicals.

- Efflorescence: Efflorescence is a condition in which white crystals form on the surface of the concrete. It is caused by the presence of soluble salts in the concrete.

5. What are the safety precautions that should be taken when working with cement?

- Wear protective clothing: Cement can irritate the skin, so it is important to wear protective clothing, such as gloves, goggles, and a mask.

- Avoid breathing in cement dust: Cement dust can cause respiratory problems, so it is important to avoid breathing it in.

- Be aware of the risks of electrical shock: Cement can conduct electricity, so it is important to be aware of the risks of electrical shock when working with it.

6. What is the difference between cement and concrete?

- Cement is a powder that is used to make concrete.

- Concrete is a mixture of cement, sand, gravel, and water.

- Concrete is much stronger than cement.

7. What are the different types of concrete finishes?

- Troweled finish: A troweled finish is a smooth, even finish that is created by troweling the concrete surface.

- Broom finish: A broom finish is a rough, textured finish that is created by brushing the concrete surface with a broom.

- Stamped finish: A stamped finish is a decorative finish that is created by stamping the concrete surface with a pattern.

8. What are the advantages of using concrete in construction?

- Strength: Concrete is a very strong material, making it ideal for structural applications.

- Durability: Concrete is a very durable material, making it resistant to wear and tear.

- Versatility: Concrete can be used in a wide variety of applications, from foundations to driveways.

- Fire resistance: Concrete is a fire-resistant material, making it ideal for buildings that are at risk of fire.

9. What are the disadvantages of using concrete in construction?

- Cost: Concrete can be a relatively expensive material, especially when compared to other materials, such as wood or steel.

- Weight: Concrete is a very heavy material, making it difficult to transport and install.

- Cracking: Concrete can crack if it is not properly installed or maintained.

10. What are the latest trends in concrete construction?

- Self-healing concrete: Self-healing concrete is a type of concrete that can repair itself when it cracks.

- Green concrete: Green concrete is a type of concrete that is made with recycled materials.

- 3D-printed concrete: 3D-printed concrete is a type of concrete that is created using a 3D printer.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cement Contractor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cement Contractor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cement contractors are responsible for the installation, repair, and maintenance of cement structures and surfaces. This includes a wide range of tasks, from pouring and finishing concrete to installing and repairing sidewalks, driveways, and patios.

1. Installation

Cement contractors are responsible for installing new concrete structures, such as foundations, walls, and floors. This involves preparing the site, pouring the concrete, and finishing the surface.

- Prepare the site by removing existing structures, leveling the ground, and installing forms.

- Pour the concrete into the forms and use a trowel to smooth and level the surface.

- Finish the surface by applying a sealant or coating to protect it from the elements.

2. Repair

Cement contractors also repair damaged concrete structures. This may involve patching cracks, replacing damaged sections, or resurfacing entire surfaces.

- Inspect the damaged area to determine the extent of the damage.

- Remove the damaged concrete and replace it with new concrete.

- Finish the surface by applying a sealant or coating to protect it from the elements.

3. Maintenance

Cement contractors also perform maintenance on concrete structures to keep them in good condition. This may involve cleaning, sealing, and resurfacing surfaces.

- Clean concrete surfaces using a power washer or other cleaning methods.

- Seal concrete surfaces to protect them from water and other damage.

- Resurface concrete surfaces to improve their appearance and durability.

4. Other Duties

In addition to the above tasks, cement contractors may also be responsible for:

- Estimating the cost of concrete projects.

- Ordering and delivering concrete materials.

- Supervising other workers.

- Ensuring that all work meets safety standards.

Interview Tips

To prepare for an interview for a cement contractor position, you can do the following:

1. Research the company and the position

Before your interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and goals. It will also help you tailor your answers to the interviewer’s questions.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. Take some time to practice your answers to these questions so that you can deliver them confidently and concisely.

3. Dress professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing a suit or dress pants and a button-down shirt or blouse. You should also make sure that your shoes are clean and polished.

4. Be on time

Punctuality is important, so make sure to arrive for your interview on time. If you are running late, call or email the interviewer to let them know.

5. Be yourself

The most important thing is to be yourself during your interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Just be confident, honest, and enthusiastic, and you will be sure to make a good impression.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cement Contractor interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.