Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Centrifugal Chiller Technician interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Centrifugal Chiller Technician so you can tailor your answers to impress potential employers.

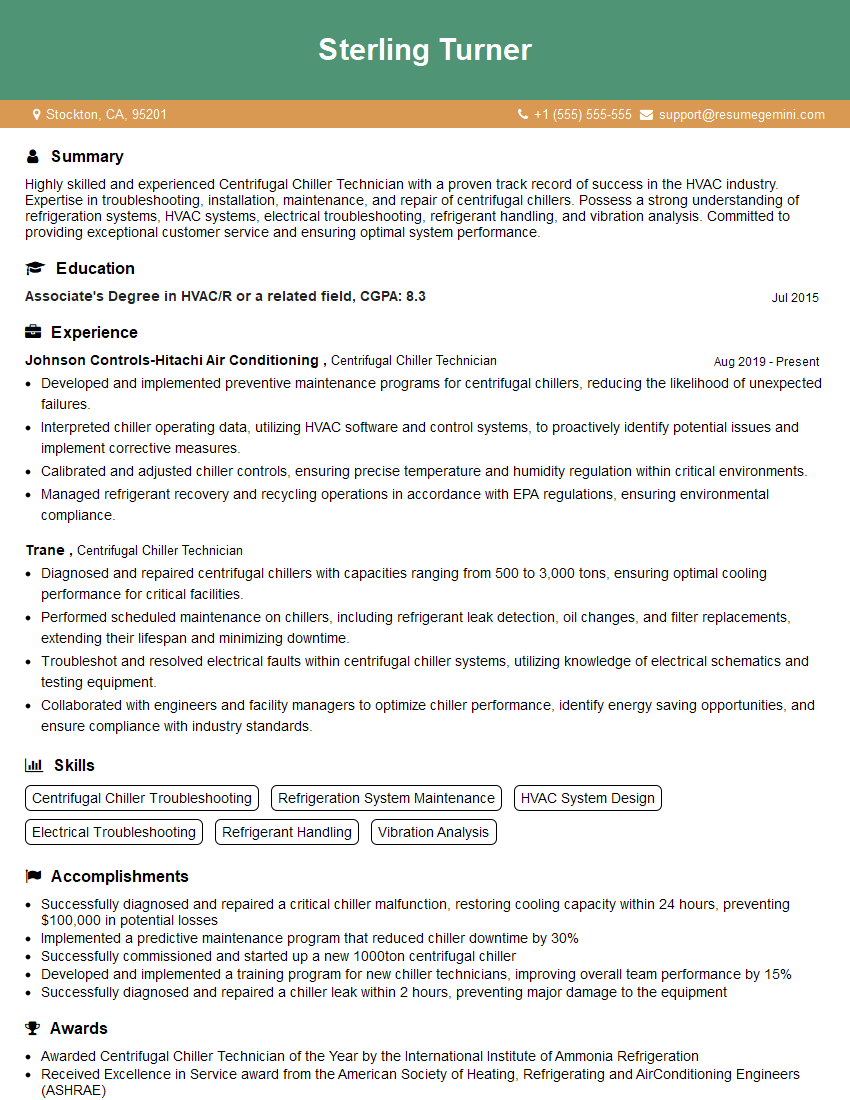

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Centrifugal Chiller Technician

1. Explain the working principle of a centrifugal chiller?

- Centrifugal chillers use the vapor-compression refrigeration cycle to remove heat from a space or process.

- The cycle begins with a compressor, which increases the pressure of the refrigerant gas. This causes the gas to heat up and enter the condenser.

- In the condenser, the gas is cooled by a fan or water, causing it to condense into a liquid.

- The liquid refrigerant then flows through an expansion valve, which reduces its pressure. This causes the liquid to evaporate and enter the evaporator.

- In the evaporator, the refrigerant absorbs heat from the space or process, causing it to boil and turn into a gas.

- The gas then returns to the compressor, and the cycle repeats.

2. What are the different types of centrifugal chillers?

- There are two main types of centrifugal chillers: air-cooled and water-cooled.

- Air-cooled chillers use fans to circulate air over the condenser coils, while water-cooled chillers use water to cool the condenser coils.

- Air-cooled chillers are typically used in smaller applications, while water-cooled chillers are typically used in larger applications.

3. What are the advantages of centrifugal chillers?

Centrifugal chillers offer a number of advantages over other types of chillers, including:

- High efficiency: Centrifugal chillers are very efficient, and can typically achieve COPs of 5 or more.

- Quiet operation: Centrifugal chillers are relatively quiet, making them ideal for use in noise-sensitive areas.

- Compact size: Centrifugal chillers are relatively compact, and can be installed in tight spaces.

- Long lifespan: Centrifugal chillers have a long lifespan, and can typically last for 20 years or more.

4. What are the disadvantages of centrifugal chillers?

Centrifugal chillers also have a few disadvantages, including:

- High cost: Centrifugal chillers are more expensive than other types of chillers.

- Complex installation: Centrifugal chillers are complex to install, and should be installed by a qualified technician.

- High maintenance requirements: Centrifugal chillers require more maintenance than other types of chillers.

5. What are the common problems that can occur with centrifugal chillers?

Centrifugal chillers can experience a number of problems, including:

- Refrigerant leaks: Refrigerant leaks can cause a loss of cooling capacity and can be dangerous if not repaired promptly.

- Compressor problems: Compressor problems can cause the chiller to lose capacity or fail completely.

- Condenser problems: Condenser problems can cause the chiller to overheat and shut down.

- Evaporator problems: Evaporator problems can cause the chiller to lose capacity or freeze up.

6. How can you troubleshoot a centrifugal chiller?

Troubleshooting a centrifugal chiller requires a systematic approach. The first step is to identify the symptoms of the problem.

Once the symptoms have been identified, the next step is to check the chiller’s operating conditions. This includes checking the refrigerant pressures, temperatures, and flows.

If the operating conditions are within acceptable limits, the next step is to inspect the chiller’s components. This includes checking the compressor, condenser, evaporator, and expansion valve.

Once the components have been inspected, the next step is to test the chiller’s electrical system. This includes checking the power supply, wiring, and controls.

If the electrical system is functioning properly, the next step is to check the chiller’s refrigerant charge. This can be done by measuring the refrigerant pressure and temperature.

Once the refrigerant charge has been checked, the next step is to perform a capacity test. This test measures the chiller’s ability to remove heat from a space or process.

If the capacity test fails, the next step is to repair or replace the chiller’s components.

7. What are the safety precautions that should be taken when working on a centrifugal chiller?

Working on a centrifugal chiller can be dangerous, and it is important to take the following safety precautions:

- Wear appropriate safety gear: This includes gloves, eye protection, and hearing protection.

- Lock out and tag out the chiller: This will prevent the chiller from being started while you are working on it.

- Relieve the refrigerant pressure: This can be done by opening the refrigerant service valves.

- Disconnect the electrical power: This will prevent the chiller from being energized while you are working on it.

8. What are the preventive maintenance tasks that should be performed on a centrifugal chiller?

Preventive maintenance is essential to keep a centrifugal chiller running efficiently and reliably. The following preventive maintenance tasks should be performed on a regular basis:

- Inspect the chiller’s exterior: This includes checking for leaks, corrosion, and damage.

- Clean the chiller’s condenser and evaporator coils: This will improve the chiller’s heat transfer efficiency.

- Check the refrigerant charge: This will ensure that the chiller has the correct amount of refrigerant.

- Check the chiller’s operating conditions: This includes checking the refrigerant pressures, temperatures, and flows.

- Test the chiller’s safety controls: This will ensure that the chiller will shut down properly in the event of a problem.

9. What are the different types of controls that can be used on a centrifugal chiller?

Centrifugal chillers can be controlled using a variety of different controls, including:

- Temperature controls: These controls regulate the temperature of the chilled water or air that is produced by the chiller.

- Pressure controls: These controls regulate the pressure of the refrigerant in the chiller.

- Flow controls: These controls regulate the flow of refrigerant through the chiller.

- Safety controls: These controls protect the chiller from damage in the event of a problem.

10. What are the latest trends in centrifugal chiller technology?

The latest trends in centrifugal chiller technology include:

- Variable-speed compressors: These compressors can adjust their speed to match the load on the chiller, which can improve efficiency.

- Magnetic-bearing compressors: These compressors use magnetic bearings instead of traditional bearings, which can reduce friction and improve reliability.

- Microchannel condensers and evaporators: These condensers and evaporators use smaller tubes than traditional condensers and evaporators, which can improve heat transfer efficiency.

- Intelligent controls: These controls can monitor the chiller’s performance and make adjustments to optimize efficiency.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Centrifugal Chiller Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Centrifugal Chiller Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Centrifugal Chiller Technicians are responsible for the maintenance, repair, and installation of centrifugal chillers, which are used to provide cooling in commercial and industrial buildings. Their key responsibilities include:

1. Preventive Maintenance

Centrifugal Chiller Technicians perform regular preventive maintenance tasks to keep chillers running efficiently and prevent breakdowns. These tasks may include:

- Inspecting and cleaning chillers

- Changing filters and oil

- Checking refrigerant levels

- Performing vibration analysis

2. Troubleshooting and Repair

Centrifugal Chiller Technicians troubleshoot and repair chillers when they break down. They use their knowledge of chiller systems to diagnose problems and make repairs. These repairs may include:

- Replacing components

- Adjusting settings

- Cleaning and repairing refrigerant leaks

- Rebuilding compressors

3. Installation and Commissioning

Centrifugal Chiller Technicians install and commission new chillers. They work with other trades to ensure that chillers are properly installed and connected. They also perform startup procedures and test chillers to make sure they are operating properly.

4. Record Keeping and Documentation

Centrifugal Chiller Technicians keep records of all maintenance, repairs, and installations. They also document their findings and recommendations. This documentation is used to track chiller performance and identify potential problems.

Interview Tips

To ace your Centrifugal Chiller Technician interview, you need to be prepared to answer questions about your experience, skills, and knowledge. Here are a few tips to help you prepare:

1. Research the Company and the Position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job. You can find information about the company on their website and in industry publications.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice answering these questions in advance so that you can deliver clear and concise responses.

3. Be Prepared to Talk About Your Experience

The interviewer will want to know about your experience as a Centrifugal Chiller Technician. Be prepared to talk about your specific skills and knowledge, as well as your experience with different types of chillers.

4. Be Enthusiastic and Professional

First impressions matter, so it is important to be enthusiastic and professional during your interview. Dress appropriately, arrive on time, and be polite to everyone you meet. Your positive attitude will make a good impression on the interviewer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Centrifugal Chiller Technician interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!