Feeling lost in a sea of interview questions? Landed that dream interview for Circulating Process Inspector but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Circulating Process Inspector interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

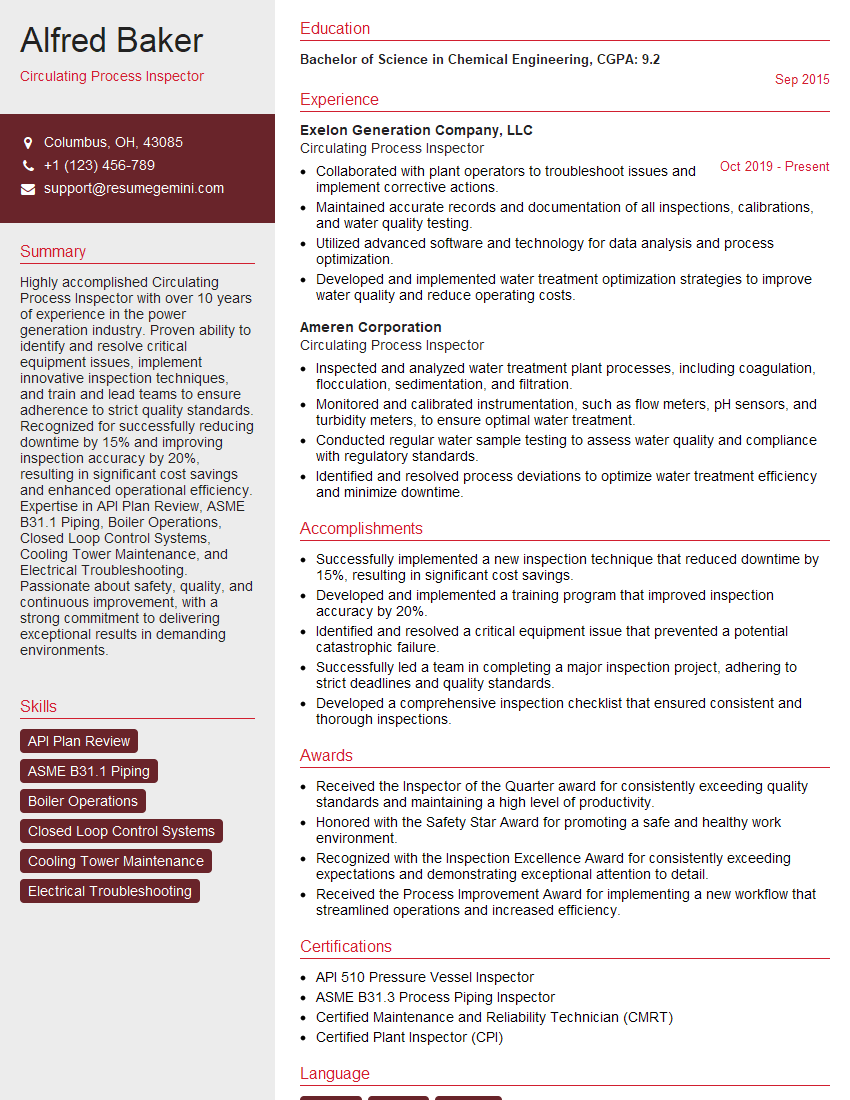

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Circulating Process Inspector

1. What are the key responsibilities of a Circulating Process Inspector?

A Circulating Process Inspector is responsible for:

- Monitoring and inspecting the equipment and processes involved in the circulation system of the plant.

- Identifying and reporting any deviations from standard operating procedures (SOPs).

- Taking corrective action to address any issues that arise.

- Maintaining accurate records of all inspections and findings.

2. What are the most common types of problems that you might encounter as a Circulating Process Inspector?

Some of the most common problems that a Circulating Process Inspector might encounter include:

Mechanical problems

- Equipment breakdowns

- Leaking pipes

- Faulty sensors

Electrical problems

- Power outages

- Short circuits

- Ground faults

Process problems

- Changes in flow rate

- Changes in pressure

- Changes in temperature

3. What are the most important skills for a Circulating Process Inspector to have?

The most important skills for a Circulating Process Inspector to have include:

- Strong attention to detail

- Analytical skills

- Problem-solving skills

- Communication skills

- Mechanical skills

4. What are the most important qualities for a Circulating Process Inspector to have?

The most important qualities for a Circulating Process Inspector to have include:

- Reliability

- Responsibility

- Teamwork

- Safety consciousness

5. What are the most important safety precautions that a Circulating Process Inspector should take?

The most important safety precautions that a Circulating Process Inspector should take include:

- Wearing appropriate personal protective equipment (PPE)

- Following all SOPs

- Being aware of potential hazards

- Reporting any unsafe conditions

6. What are the most important maintenance tasks that a Circulating Process Inspector should perform?

The most important maintenance tasks that a Circulating Process Inspector should perform include:

- Inspecting equipment

- Lubricating equipment

- Replacing filters

- Calibrating sensors

7. What are the most important troubleshooting techniques that a Circulating Process Inspector should know?

The most important troubleshooting techniques that a Circulating Process Inspector should know include:

- Process of elimination

- Divide and conquer

- Root cause analysis

8. What are the most important reporting requirements for a Circulating Process Inspector?

The most important reporting requirements for a Circulating Process Inspector include:

- Inspection reports

- Maintenance reports

- Troubleshooting reports

9. What are the most important quality control procedures for a Circulating Process Inspector?

The most important quality control procedures for a Circulating Process Inspector include:

- Following SOPs

- Inspecting equipment

- Testing products

- Recording data

10. What are the most important training requirements for a Circulating Process Inspector?

The most important training requirements for a Circulating Process Inspector include:

- Basic process technology

- Process inspection techniques

- Maintenance procedures

- Troubleshooting techniques

- Reporting procedures

- Quality control procedures

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Circulating Process Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Circulating Process Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Circulating Process Inspectors undertake various critical responsibilities to ensure smooth and efficient operations in semiconductor manufacturing facilities.

1. Inspection and Monitoring

Inspect and monitor circulating process equipment, including water and gas lines, to ensure optimal performance and compliance with specifications.

- Conduct visual inspections and employ specialized tools to detect leaks, blockages, and other anomalies.

- Monitor system parameters such as pressure, flow rate, and temperature to identify deviations and prevent failures.

2. Maintenance and Repair

Perform routine maintenance tasks and repairs to keep circulating process equipment operating efficiently.

- Replace filters, clean components, and lubricate moving parts to prevent malfunctions.

- Diagnose and repair leaks, blockages, and other issues that may arise.

3. Troubleshooting and Problem-Solving

Troubleshoot and resolve issues that affect circulating process equipment to minimize downtime.

- Analyze data, consult technical documentation, and apply troubleshooting techniques to identify root causes.

- Develop and implement corrective actions to restore system functionality and prevent future occurrences.

4. Documentation and Reporting

Maintain accurate records and provide reports on circulating process equipment performance and maintenance activities.

- Document inspection results, maintenance logs, and troubleshooting procedures.

- Generate reports to inform management and support continuous improvement initiatives.

Interview Tips

To prepare effectively for an interview as a Circulating Process Inspector, consider the following tips and hacks:

1. Research the Company and Role

Thoroughly research the company’s profile, industry standing, and specific requirements for the Circulating Process Inspector role. This knowledge will enable you to tailor your responses and demonstrate your alignment with the company’s goals.

- Visit the company’s website, LinkedIn page, and any available industry news articles.

- Review the job description carefully and identify the key responsibilities and qualifications required.

2. Highlight Your Technical Skills

During the interview, emphasize your technical proficiency in inspecting, maintaining, and troubleshooting circulating process equipment. Provide specific examples of your experience.

- Describe your expertise in using specialized tools and techniques for detecting and resolving issues.

- Quantify your accomplishments by providing metrics on improved equipment performance or reduced downtime.

3. Showcase Your Problem-Solving Abilities

Highlight your problem-solving abilities by presenting real-life examples of how you have successfully diagnosed and resolved complex issues with circulating process equipment.

- Explain your analytical approach and the steps you took to identify root causes.

- Discuss the innovative solutions you implemented to restore system functionality.

4. Communicate Effectively

Practice clear and concise communication skills, as you will need to effectively convey your findings and recommendations to various stakeholders, including engineers, technicians, and management.

- Prepare concise and well-organized answers to common interview questions.

- Demonstrate active listening skills and ask thoughtful questions to engage with the interviewers.

Next Step:

Now that you’re armed with the knowledge of Circulating Process Inspector interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Circulating Process Inspector positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini