Are you gearing up for a career in Corrosion Control Fitter? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Corrosion Control Fitter and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

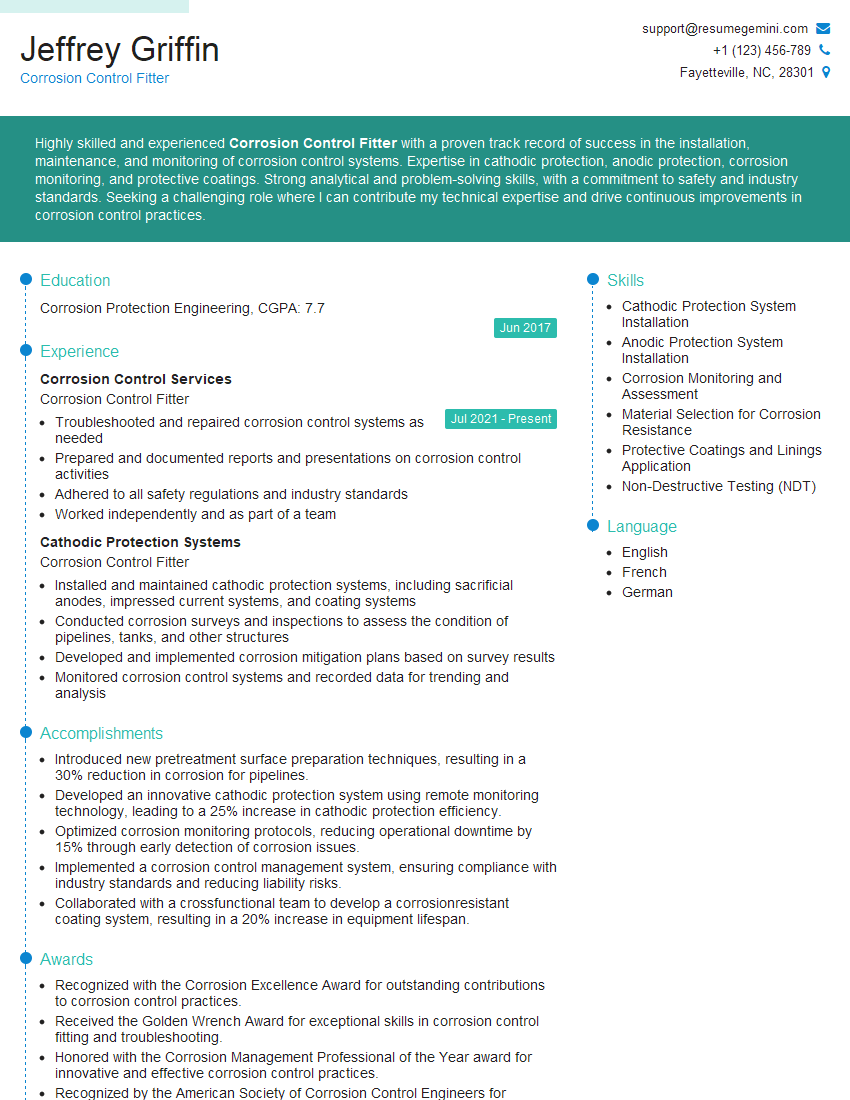

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Corrosion Control Fitter

1. Explain the different types of corrosion and their causes?

- Uniform corrosion: This is the most common type of corrosion, and it occurs when the entire surface of a metal is attacked by a corrosive agent. The most common cause of uniform corrosion is exposure to water or moisture.

- Pitting corrosion: This type of corrosion occurs when small pits or holes form on the surface of a metal. Pitting corrosion is often caused by exposure to chloride ions.

- Crevice corrosion: This type of corrosion occurs in crevices or areas where there is a lack of oxygen. Crevice corrosion is often caused by exposure to stagnant water or other liquids.

- Galvanic corrosion: This type of corrosion occurs when two dissimilar metals are in contact with each other in the presence of an electrolyte. The more active metal will corrode.

- Stress corrosion cracking: This type of corrosion occurs when a metal is under stress and exposed to a corrosive agent. Stress corrosion cracking can lead to the sudden and catastrophic failure of a metal component.

2. What are the different methods of corrosion control?

Coatings

- Metallic coatings: These coatings are applied to the surface of a metal to protect it from corrosion. Metallic coatings can be made of zinc, aluminum, or other metals.

- Organic coatings: These coatings are applied to the surface of a metal to provide a barrier between the metal and the corrosive environment. Organic coatings can be made of paint, epoxy, or other materials.

Cathodic protection

- Sacrificial anodes: These anodes are made of a more active metal than the metal they are protecting. The sacrificial anode corrodes instead of the metal it is protecting.

- Impressed current cathodic protection: This system uses an external power source to provide cathodic protection to a metal. Impressed current cathodic protection is often used to protect large metal structures, such as pipelines and bridges.

Inhibitors

- Anodic inhibitors: These inhibitors prevent the metal from corroding by forming a protective film on the surface of the metal.

- Cathodic inhibitors: These inhibitors prevent the metal from corroding by reducing the rate of the cathodic reaction.

3. What are the different materials used in corrosion control and their applications?

- Stainless steel: Stainless steel is a corrosion-resistant alloy of iron, chromium, and other metals. Stainless steel is used in a variety of applications, including food processing, chemical processing, and marine environments.

- Aluminum: Aluminum is a lightweight and corrosion-resistant metal. Aluminum is used in a variety of applications, including aerospace, automotive, and construction.

- Titanium: Titanium is a strong and corrosion-resistant metal. Titanium is used in a variety of applications, including aerospace, medical, and chemical processing.

- Nickel alloys: Nickel alloys are corrosion-resistant alloys of nickel, chromium, and other metals. Nickel alloys are used in a variety of applications, including chemical processing, marine environments, and aerospace.

4. What are the different tools and techniques used in corrosion control?

- Visual inspection: This is the most basic method of corrosion control. Visual inspection involves looking for signs of corrosion, such as rust, pitting, or cracking.

- Non-destructive testing: This type of testing involves using specialized equipment to detect corrosion without damaging the metal. Non-destructive testing methods include ultrasonic testing, radiographic testing, and magnetic particle testing.

- Electrochemical testing: This type of testing involves using electrochemical techniques to measure the corrosion rate of a metal. Electrochemical testing methods include potentiodynamic polarization and electrochemical impedance spectroscopy.

5. What are the different safety precautions that must be taken when working with corrosion control materials and equipment?

- Wear appropriate personal protective equipment (PPE): This includes gloves, safety glasses, and a respirator.

- Be aware of the hazards of the materials you are working with: Read the safety data sheets (SDSs) for all of the materials you are using.

- Follow all safety procedures: Do not deviate from the established safety procedures.

- Be aware of your surroundings: Be aware of the potential hazards in your work area.

- Report any accidents or incidents immediately: Report any accidents or incidents to your supervisor immediately.

6. What are the different types of corrosion control systems?

- Passive corrosion control systems: These systems prevent corrosion by forming a protective layer on the surface of the metal. Passive corrosion control systems include coatings, cathodic protection, and inhibitors.

- Active corrosion control systems: These systems remove corrosion from the surface of the metal. Active corrosion control systems include mechanical cleaning and chemical cleaning.

7. What are the different factors that affect the rate of corrosion?

- The type of metal: Some metals are more corrosion-resistant than others.

- The environment: The corrosive environment can affect the rate of corrosion. Factors such as temperature, humidity, and the presence of corrosive agents can all affect the rate of corrosion.

- The design of the metal structure: The design of the metal structure can affect the rate of corrosion. Factors such as the presence of crevices and the use of dissimilar metals can all affect the rate of corrosion.

- The use of corrosion control measures: The use of corrosion control measures can reduce the rate of corrosion.

8. What are the different methods of cathodic protection?

- Sacrificial anodes: These anodes are made of a more active metal than the metal they are protecting. The sacrificial anode corrodes instead of the metal it is protecting.

- Impressed current cathodic protection: This system uses an external power source to provide cathodic protection to a metal. Impressed current cathodic protection is often used to protect large metal structures, such as pipelines and bridges.

9. What are the different types of inhibitors?

- Anodic inhibitors: These inhibitors prevent the metal from corroding by forming a protective film on the surface of the metal.

- Cathodic inhibitors: These inhibitors prevent the metal from corroding by reducing the rate of the cathodic reaction.

10. What are the different types of coatings that can be used for corrosion control?

- Metallic coatings: These coatings are applied to the surface of a metal to protect it from corrosion. Metallic coatings can be made of zinc, aluminum, or other metals.

- Organic coatings: These coatings are applied to the surface of a metal to provide a barrier between the metal and the corrosive environment. Organic coatings can be made of paint, epoxy, or other materials.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Corrosion Control Fitter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Corrosion Control Fitter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Corrosion Control Fitters are responsible for installing, maintaining, and repairing corrosion control systems to protect metal structures and equipment from corrosion. Key responsibilities include:

1. Installing Corrosion Control Systems

Fit corrosion-resistant materials, such as coatings, sealants, and cathodic protection systems, to protect metal surfaces from corrosive environments.

- Applying protective coatings and linings to surfaces.

- Installing sacrificial anodes and cathodic protection systems.

2. Maintaining and Repairing Corrosion Control Systems

Inspect corrosion control systems regularly to ensure they are functioning properly and make necessary repairs and adjustments.

- Conducting periodic inspections to identify and repair corrosion damage.

- Replacing or repairing damaged coatings and sealants.

3. Monitoring and Testing

Monitor corrosion rates and test the effectiveness of corrosion control systems to ensure their ongoing protection.

- Conducting corrosion tests and monitoring data to assess the effectiveness of corrosion control measures.

- Analyzing test results and making recommendations for improvements.

4. Working with Engineers and Other Professionals

Collaborate with engineers, inspectors, and other professionals to develop and implement corrosion control strategies.

- Consulting with engineers to design and specify corrosion control systems.

- Working with inspectors to assess the condition of corrosion control systems and identify areas for improvement.

Interview Tips

Preparing for a Corrosion Control Fitter interview requires a combination of technical knowledge and interview skills. Here are some tips to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s products, services, and commitment to corrosion control. Research current industry trends and best practices to demonstrate your knowledge of the field.

2. Highlight Your Technical Skills

Emphasize your expertise in corrosion control techniques, materials, and equipment. Quantify your experience with specific projects, including the types of systems installed, maintained, and repaired.

3. Showcase Your Problem-Solving Abilities

Provide examples of situations where you identified and solved corrosion problems effectively. Highlight your analytical skills, attention to detail, and ability to work independently and as part of a team.

4. Practice Your Communication Skills

Be prepared to clearly articulate your technical knowledge and experience to both technical and non-technical interviewers. Practice explaining complex concepts in a concise and engaging manner.

5. Prepare Industry-Specific Questions

Asking informed questions about the company’s corrosion control strategies, challenges, and future plans demonstrate your enthusiasm and interest in the position.

6. Dress Professionally and Arrive Punctually

Make a positive first impression by dressing appropriately and arriving on time for the interview. Maintain a professional demeanor throughout the process.

Next Step:

Now that you’re armed with the knowledge of Corrosion Control Fitter interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Corrosion Control Fitter positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini