Are you gearing up for a career in Cotton Picker Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Cotton Picker Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

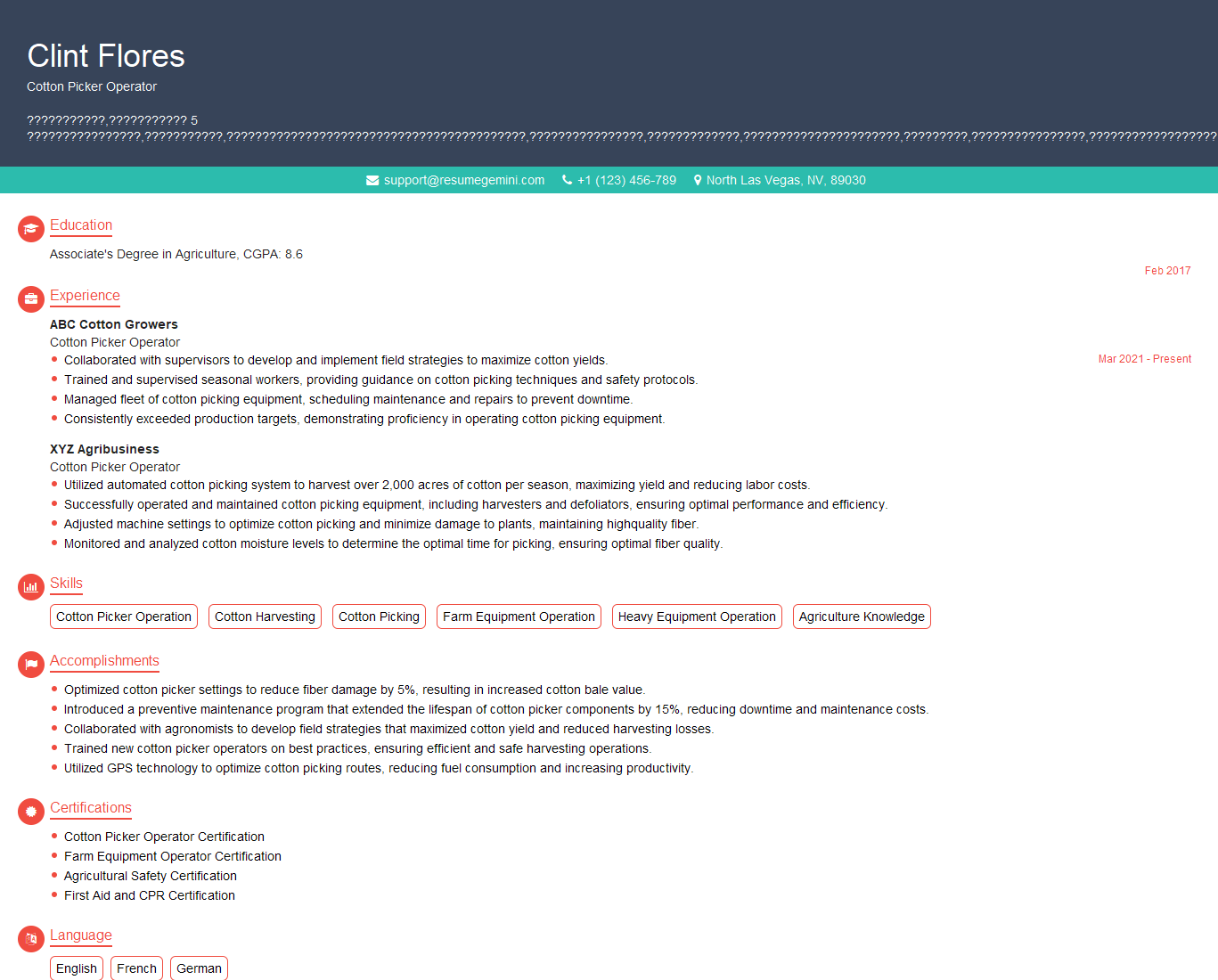

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cotton Picker Operator

1. Describe the process of operating a cotton picker machine?

The process of operating a cotton picker machine involves the following steps:

- Prepare the machine for operation by checking the oil and fuel levels, and ensuring that all safety features are in place.

- Drive the machine into the field and align it with the rows of cotton plants.

- Lower the picking head to the ground and engage the picking mechanism.

- Drive the machine forward at a steady pace, allowing the picking head to collect the cotton bolls.

- Monitor the operation of the machine and make adjustments as needed to ensure optimal performance.

- Unload the collected cotton bolls into a trailer or other storage container.

- Clean and maintain the machine after each use to ensure its longevity and optimal performance.

2. What are the different types of cotton picker machines and their advantages and disadvantages?

Self-propelled cotton picker

- Advantages: High capacity, fast picking speed, and can operate in various field conditions.

- Disadvantages: Expensive, requires skilled operators, and can cause damage to cotton plants.

Pull-type cotton picker

- Advantages: Lower cost, easier to operate, and less likely to damage cotton plants.

- Disadvantages: Lower capacity and slower picking speed than self-propelled pickers.

Modular cotton picker

- Advantages: Can be customized to meet specific needs, can be used for multiple crops, and is relatively inexpensive.

- Disadvantages: Lower capacity and slower picking speed than self-propelled pickers.

3. What are the key factors that affect the efficiency of a cotton picker machine?

The key factors that affect the efficiency of a cotton picker machine include:

- The type of cotton picker machine being used.

- The condition of the cotton field (e.g., the height and density of the plants, the presence of weeds or other obstacles).

- The skill and experience of the operator.

- The weather conditions (e.g., the temperature, humidity, and wind speed).

- The maintenance and calibration of the machine.

4. What are the safety precautions that should be taken when operating a cotton picker machine?

The safety precautions that should be taken when operating a cotton picker machine include:

- Always wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and earplugs.

- Inspect the machine thoroughly before each use and ensure that all safety features are in place and functioning properly.

- Never operate the machine under the influence of alcohol or drugs.

- Be aware of your surroundings and avoid operating the machine near people, animals, or other obstacles.

- Never attempt to repair or adjust the machine while it is running.

- Follow all manufacturer’s instructions and safety guidelines.

5. What are the common problems that can occur with cotton picker machines and how can they be resolved?

Some common problems that can occur with cotton picker machines include:

- Plugged spindles: This can be resolved by cleaning the spindles with a brush or compressed air.

- Broken belts: This can be resolved by replacing the broken belt.

- Hydraulic leaks: This can be resolved by tightening the loose fittings or replacing the damaged hydraulic lines.

- Electrical problems: This can be resolved by checking the wiring and connections, and replacing any damaged components.

- Engine problems: This can be resolved by checking the oil and fuel levels, and servicing the engine as needed.

6. What are the maintenance and calibration procedures that should be performed on a cotton picker machine?

The maintenance and calibration procedures that should be performed on a cotton picker machine include:

- Regularly cleaning the machine to remove dirt, dust, and debris.

- Inspecting the machine for any signs of damage or wear.

- Lubricating the moving parts of the machine.

- Adjusting the picking head to ensure that it is properly aligned with the cotton plants.

- Calibrating the machine to ensure that it is picking the cotton at the desired rate.

7. What are the different types of cotton harvesting methods and how do they compare to mechanical picking?

The different types of cotton harvesting methods include:

- Hand picking: This is the traditional method of harvesting cotton, but it is very labor-intensive and time-consuming.

- Mechanical picking: This method uses machines to harvest the cotton, and it is much faster and more efficient than hand picking.

- Chemical defoliation: This method uses chemicals to remove the leaves from the cotton plants, making it easier to mechanically harvest the cotton.

Mechanical picking is the most common method of harvesting cotton today, as it is the most efficient and cost-effective method.

8. What are the environmental impacts of cotton harvesting and how can they be minimized?

The environmental impacts of cotton harvesting include:

- Soil erosion: Mechanical harvesting can cause soil erosion, especially on sloping land.

- Water pollution: Runoff from cotton fields can contain pesticides and other chemicals that can pollute water sources.

- Air pollution: The operation of cotton harvesting machines can release air pollutants, such as dust and exhaust fumes.

The environmental impacts of cotton harvesting can be minimized by using conservation tillage practices, planting cover crops, and using precision agriculture techniques to reduce the use of pesticides and fertilizers.

9. What are the economic factors that affect the profitability of cotton harvesting?

The economic factors that affect the profitability of cotton harvesting include:

- The price of cotton: The price of cotton is determined by the global supply and demand for cotton.

- The cost of labor: The cost of labor for cotton harvesting varies depending on the region and the availability of labor.

- The cost of fuel: The cost of fuel for cotton harvesting machines can vary depending on the price of fuel.

- The efficiency of the harvesting operation: The efficiency of the harvesting operation can be affected by the type of harvesting equipment used, the skill of the operator, and the weather conditions.

10. What are the future trends in cotton harvesting technology?

The future trends in cotton harvesting technology include:

- The development of more efficient harvesting machines: Harvesting machines are becoming more efficient, allowing farmers to harvest more cotton with less labor.

- The use of precision agriculture techniques: Precision agriculture techniques are being used to improve the efficiency and profitability of cotton harvesting.

- The development of new cotton varieties: New cotton varieties are being developed that are more resistant to pests and diseases, and that produce higher yields.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cotton Picker Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cotton Picker Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Cotton Picker Operator

Cotton Picker Operators play a crucial role in the efficient harvesting of cotton crops. Their key responsibilities include:

1. Operating and Maintaining Cotton Picker

- Skilled operation of cotton picker machinery to harvest cotton.

- Conduct regular maintenance and inspections to maintain optimal performance.

2. Crop Monitoring and Harvesting

- Monitoring crop maturity and weather conditions to determine optimal harvesting time.

- Adjusting picker settings to maximize yield while minimizing damage.

3. Bale Handling and Quality Control

- Ensuring proper handling of harvested cotton bales.

- Monitoring the quality of the raw cotton and identifying any defects or contamination.

4. Safety and Compliance

- Adhering to all safety protocols, including wearing appropriate protective gear.

- Complying with industry regulations and environmental standards.

Interview Preparation Tips for Cotton Picker Operator

To excel in a Cotton Picker Operator interview, consider the following tips:

1. Research the Company and Role

- Familiarize yourself with the company’s operations, industry trends, and specific requirements for the role.

- This demonstrates your interest and preparedness.

2. Highlight Relevant Skills and Experience

- Emphasize your proficiency in operating cotton picker machinery, including model-specific knowledge.

- Quantify your experience in terms of acres harvested or yield achieved.

3. Showcase Mechanical Aptitude

- Highlight your understanding of cotton picker mechanics and your ability to troubleshoot common issues.

- Discuss your experience in performing regular maintenance and repairs on agricultural equipment.

4. Emphasize Safety Consciousness

- Convey your strong commitment to safety practices.

- Describe your knowledge of safety protocols and your experience in following them diligently.

5. Practice Answering Common Interview Questions

Prepare answers to frequently asked interview questions, such as:

- Tell me about your experience with cotton picker operations.

- How do you handle challenges with harvesting different cotton cultivars?

- What is your approach to maintaining and troubleshooting cotton picker equipment?

By incorporating these tips into your interview preparation, you can effectively showcase your qualifications and increase your chances of success.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cotton Picker Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.