Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Cracking and Fanning Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Cracking and Fanning Machine Operator so you can tailor your answers to impress potential employers.

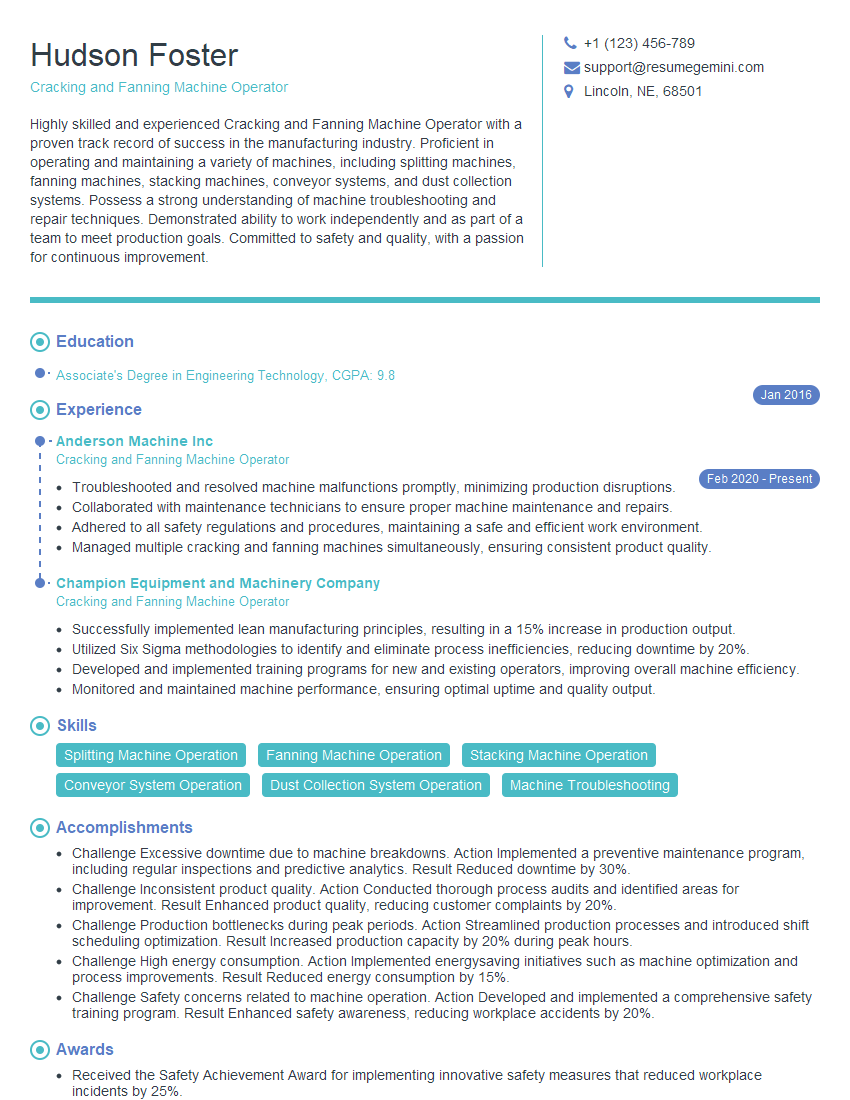

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cracking and Fanning Machine Operator

1. Describe the key functions and responsibilities of a Cracking and Fanning Machine Operator?

- Operate and monitor cracking and fanning machines to separate and sort seeds, grains, or other materials.

- Adjust machine settings to achieve desired results, such as size, density, or purity.

- Monitor the flow of materials through the machines and make adjustments as needed.

- Maintain and clean the machines to ensure optimal performance and longevity.

- Inspect finished products to ensure quality and meet specifications.

2. What are the different types of cracking and fanning machines and their applications?

- Reel-type cracking machines: Used for cracking delicate seeds or grains, such as wheat, barley, or oats.

- Disc-type cracking machines: Used for cracking harder materials, such as corn, soybeans, or beans.

- Gravity separators: Used for separating materials based on their density, such as separating hulls from kernels.

- Air separators: Used for separating materials based on their aerodynamic properties, such as separating light chaff from heavy seeds.

3. What is the importance of proper maintenance and calibration of cracking and fanning machines?

- Ensures optimal performance and efficiency.

- Prevents breakdowns and costly repairs.

- Maximizes product quality and yield.

- Reduces downtime and production losses.

4. Describe the safety protocols and procedures that should be followed when operating cracking and fanning machines?

- Wear appropriate personal protective equipment (PPE).

- Keep the work area clean and free of hazards.

- Follow lockout/tagout procedures during maintenance.

- Be aware of moving parts and potential pinch points.

- Report any malfunctions or safety concerns promptly.

5. How do you troubleshoot common problems that may occur with cracking and fanning machines?

- Reduced cracking efficiency: Check blade sharpness, machine settings, or material flow.

- Poor separation: Adjust fan speed, screen size, or material flow.

- Machine vibration: Check for loose bolts, misalignment, or bearing issues.

- Overheating: Check for clogged screens, blocked air vents, or excessive load.

- Electrical faults: Check wiring, fuses, or circuit breakers.

6. What are some techniques for optimizing the performance of cracking and fanning machines?

- Use sharp blades and screens to maximize cracking and separation.

- Adjust machine settings to suit the specific material being processed.

- Monitor material flow and make adjustments as needed to prevent blockages and ensure efficient operation.

- Perform regular maintenance and calibration to keep the machines running smoothly.

- Use high-quality materials and components to ensure durability and longevity.

7. How do you ensure the quality of cracked and fanned products?

- Inspect the finished products for desired size, density, and purity.

- Use quality control tools, such as sieves or analyzers, to verify product specifications.

- Monitor the machines’ performance and make adjustments as needed to maintain consistent quality.

- Document and record quality assurance procedures to ensure traceability and compliance.

8. What is your experience with different types of materials processed on cracking and fanning machines?

9. Can you describe a challenging situation you faced while operating a cracking and fanning machine and how you resolved it?

10. How do you stay updated on the latest advancements in cracking and fanning technology?

- Read industry publications and attend trade shows.

- Consult with equipment manufacturers and suppliers.

- Participate in online forums and discussions.

- Research best practices and emerging technologies.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cracking and Fanning Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cracking and Fanning Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Operate and maintain cracking and fanning machines

Keep machines clean and well-oiled. Make necessary adjustments to ensure proper operation and product quality.

2. Monitor production and make adjustments as needed

Monitor production rates, product quality, and machine performance. Make adjustments to maintain optimal production levels and quality standards.

3. Troubleshoot and resolve machine problems

Identify and resolve machine problems promptly to minimize downtime. Consult with maintenance personnel as needed.

4. Inspect and maintain inventory

Inspect and maintain inventory of raw materials and finished products. Ensure proper storage and handling to prevent damage or contamination.

Interview Tips

The key to acing an interview for a Cracking and Fanning Machine Operator position is to demonstrate your knowledge of the job responsibilities, your experience operating and maintaining similar equipment, and your ability to work independently and as part of a team. Here are some specific tips to help you prepare for the interview:

Also, it is important to note that candidates may not have experience with every single responsibility listed in the job description. In such cases, highlight your transferable skills and eagerness to learn.

1. Research the company and the position

Take some time to research the company you are interviewing with, as well as the specific position you are applying for. This will help you understand the company’s culture, values, and goals, and tailor your answers accordingly.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Be prepared to discuss your experience and skills

The interviewer will want to know about your experience operating and maintaining cracking and fanning machines, as well as your other relevant skills. Be prepared to discuss your experience in detail, and highlight any specific skills or accomplishments that are relevant to the position.

4. Be prepared to talk about your safety record

Safety is a critical aspect of working as a Cracking and Fanning Machine Operator. Be prepared to discuss your safety record, and highlight any specific safety measures or initiatives that you have implemented.

5. Be prepared to answer questions about your teamwork skills

Cracking and Fanning Machine Operators often work as part of a team. Be prepared to answer questions about your teamwork skills, and highlight any specific examples of how you have worked effectively as part of a team.

6. Dress professionally and arrive on time

First impressions matter. Dress professionally for your interview, and arrive on time. This will show the interviewer that you are serious about the position and that you respect their time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cracking and Fanning Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!