Are you gearing up for a career in Cutting Machine Tender? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Cutting Machine Tender and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

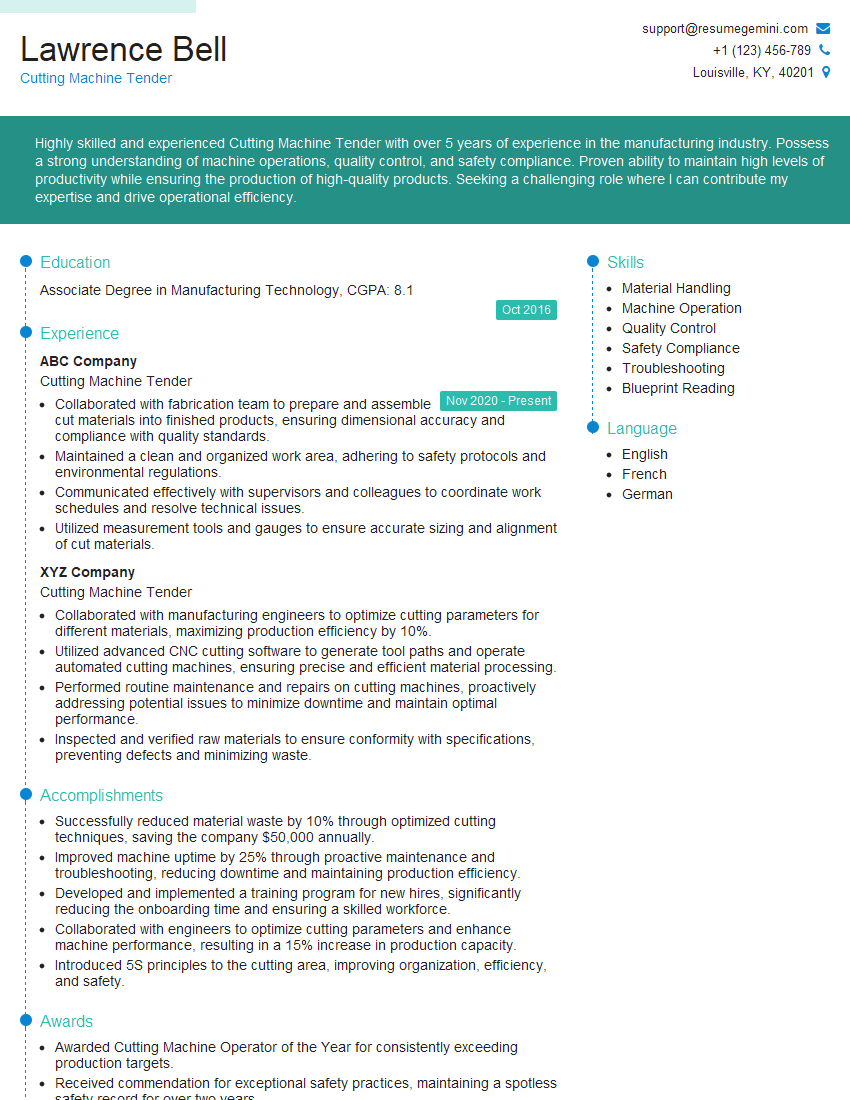

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Cutting Machine Tender

1. How do you ensure the accuracy and precision of cuts made by the cutting machine?

To ensure the accuracy and precision of the cuts made by the cutting machine, I meticulously follow these steps:

- Prior to operation, I thoroughly inspect the machine to ensure its proper functioning and calibration.

- I carefully measure and mark the materials to be cut, using precise measuring tools like rulers or calipers.

- I meticulously set up the cutting machine, aligning the materials and adjusting the cutting parameters as per the specifications.

- During the cutting operation, I monitor the process closely to detect any deviations or inconsistencies.

- After each cut, I thoroughly inspect the cut pieces to ensure they meet the required dimensions and tolerances.

2. Describe the different types of cutting techniques used on the cutting machine.

Mechanical Cutting

- Shear Cutting: Utilizes two blades that slide past each other to shear the material.

- Die Cutting: Employs a sharp die to cut the material against a backing material.

- Punching: Uses a punch and die to create holes or shapes in the material.

Thermal Cutting

- Laser Cutting: Focuses a high-powered laser beam to melt and vaporize the material.

- Plasma Cutting: Employs a plasma arc to cut through conductive materials.

Waterjet Cutting

- Utilizes a high-pressure stream of water mixed with abrasive particles to cut through various materials.

3. How do you maintain and troubleshoot common issues with the cutting machine?

To ensure optimal performance and longevity of the cutting machine, I diligently perform the following maintenance tasks:

- Regularly clean and lubricate all moving parts to minimize wear and friction.

- Inspect and replace worn or damaged blades, dies, or other cutting tools to maintain sharpness and precision.

- Calibrate the machine periodically to ensure accurate cutting dimensions.

In case of any issues, I follow a systematic troubleshooting approach:

- Diagnose the problem by observing the symptoms and error messages.

- Consult technical manuals and consult with experienced colleagues to identify potential causes.

- Systematically isolate the issue by checking individual components and parameters.

- Implement corrective measures, such as replacing faulty parts or adjusting settings.

4. What safety precautions do you take when operating the cutting machine?

- Wear appropriate personal protective equipment (PPE), including safety glasses, earplugs, and gloves.

- Ensure the machine is properly grounded to prevent electrical hazards.

- Keep the work area clean and free of debris to prevent tripping or slipping.

- Never operate the machine with loose clothing or jewelry that could get caught in moving parts.

- Always follow established safety procedures and lockout/tagout protocols.

5. How do you optimize the cutting process for different materials and thicknesses?

To optimize the cutting process for different materials and thicknesses, I consider the following factors:

- Material properties: Different materials have varying hardness, toughness, and melting points.

- Thickness: Thicker materials require higher cutting forces or power.

- Cutting technique: The choice of cutting technique depends on material compatibility and desired precision.

Based on these considerations, I adjust the following parameters:

- Cutting speed: Higher speeds may be suitable for softer materials, while slower speeds are necessary for hard or thick materials.

- Cutting force or power: More force or power is required to cut thicker or harder materials.

- Blade or tool selection: The type and sharpness of the blade or tool can impact the quality and efficiency of the cut.

6. How do you handle scrap material and ensure proper waste disposal?

- Collect and segregate scrap material based on its composition and disposal requirements.

- Dispose of scrap metal through authorized recycling facilities to minimize environmental impact.

- Properly dispose of non-recyclable materials, such as plastics or rubber, in accordance with local regulations.

- Maintain a clean and organized work area to prevent accumulation of scrap and debris.

7. What is your experience with quality control procedures for cutting operations?

Throughout my cutting machine operation experience, I have consistently adhered to stringent quality control procedures to ensure the accuracy and precision of the final products:

- Thoroughly inspect raw materials before cutting to identify any defects or inconsistencies.

- Regularly calibrate and maintain the cutting machine to minimize deviations and ensure consistent performance.

- Implement statistical process control (SPC) techniques to monitor and adjust cutting parameters for optimal results.

- Conduct post-cut inspections to verify dimensional accuracy, surface finish, and adherence to specifications.

8. Describe your experience in working with computerized cutting machines.

I have extensive experience in operating computerized cutting machines, utilizing advanced software and control systems to achieve precise and efficient cutting results:

- Proficient in programming and operating CNC (Computer Numerical Control) cutting machines.

- Capable of interpreting complex CAD (Computer-Aided Design) drawings and generating cutting paths.

- Familiar with various software applications for cutting optimization and process automation.

- Utilize computer-aided manufacturing (CAM) systems to enhance productivity and minimize errors.

9. How do you stay updated on the latest cutting technologies and best practices?

- Attend industry conferences, workshops, and training programs to learn about new techniques and equipment.

- Read technical journals, white papers, and online resources to stay abreast of advancements in cutting technology.

- Engage in discussions with colleagues and industry experts to exchange knowledge and insights.

- Seek opportunities to experiment with different cutting methods and optimize processes.

10. What are your career goals and how does this position align with them?

My career goal is to excel as a highly skilled Cutting Machine Tender, utilizing my expertise to contribute to the efficiency and productivity of manufacturing operations.

This position aligns perfectly with my aspirations as it provides an opportunity to:

- Apply my technical skills in operating and maintaining cutting machines.

- Enhance my knowledge of cutting techniques and best practices.

- Contribute to the production of high-quality products and meet customer requirements.

- Advance my career within the manufacturing industry and assume responsibilities in process improvement and leadership.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Cutting Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Cutting Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Cutting Machine Tenders are responsible for operating and maintaining cutting machines, which cut materials such as metal, plastic, and fabric into specific shapes and sizes. They are responsible for ensuring that the machines are operating safely and efficiently, and that the materials are cut to the correct specifications.

1. Machine Operation

Cutting Machine Tenders are responsible for operating the cutting machines according to the manufacturer’s instructions. They are responsible for loading and unloading the materials to be cut, and for setting up the machine to the correct cutting specifications. They also monitor the cutting process to ensure that the materials are being cut to the correct size and shape.

2. Machine Maintenance

Cutting Machine Tenders are responsible for maintaining the cutting machines in good working order. This includes cleaning and lubricating the machines, and inspecting them for any signs of wear or damage. They are also responsible for making any necessary repairs or adjustments to the machines.

3. Safety

Cutting Machine Tenders are responsible for following all safety procedures when operating the cutting machines. This includes wearing appropriate safety gear, such as gloves and safety glasses, and ensuring that the work area is clean and free of hazards.

4. Quality Control

Cutting Machine Tenders are responsible for ensuring that the materials are cut to the correct specifications. They are responsible for inspecting the cut materials to ensure that they are the correct size and shape, and that they meet the required quality standards.

Interview Tips

If you are interviewing for a position as a Cutting Machine Tender, there are a few things you can do to prepare for the interview and increase your chances of success.

1. Research the company and the position

Before you go to the interview, it is important to do your research and learn as much as you can about the company and the position you are applying for. This will help you to understand the company’s culture and values, and to tailor your answers to the specific requirements of the position.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly in the interview.

3. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows that you are serious about the position and that you respect the interviewer’s time.

4. Be prepared to talk about your experience

The interviewer will likely ask you about your experience operating cutting machines. Be prepared to talk about your skills and knowledge in this area, and to provide examples of your work.

5. Be prepared to answer questions about safety

Safety is an important aspect of operating cutting machines. Be prepared to answer questions about your safety procedures and your knowledge of safety regulations.

6. Be prepared to ask questions

The end of the interview is a good opportunity to ask the interviewer questions about the position and the company. This shows that you are interested in the position and that you are eager to learn more about the company. Asking a question or two also gives you the opportunity to clarify any information that was discussed during the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Cutting Machine Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!