Feeling lost in a sea of interview questions? Landed that dream interview for Decorative Cutting Machine Tender but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Decorative Cutting Machine Tender interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

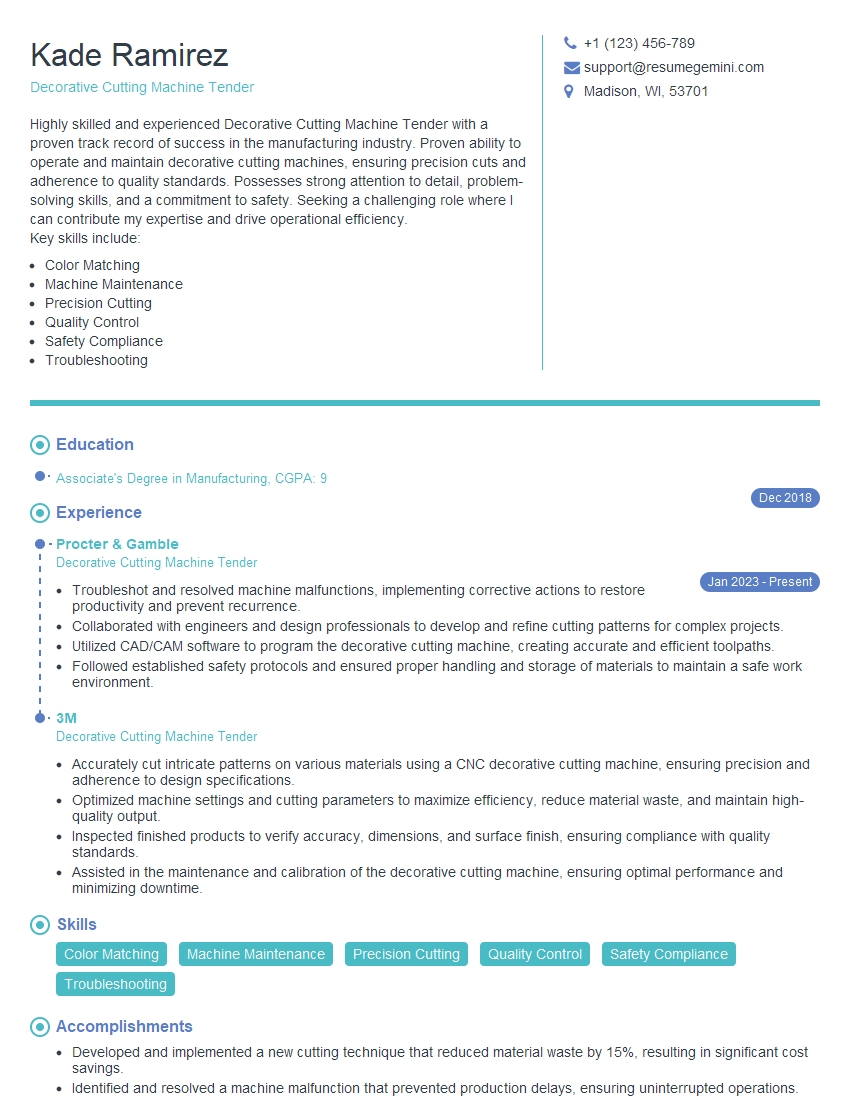

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Decorative Cutting Machine Tender

1. What knowledge is required to operate a decorative cutting machine?

To operate a decorative cutting machine, a thorough understanding of the following is essential:

- The machine’s components, their functions, and how they work together.

- The different types of materials that can be cut with the machine and their respective cutting parameters.

- The various cutting techniques and how to adjust the machine to achieve the desired results.

- Safety protocols and maintenance procedures to ensure the safe and efficient operation of the machine.

2. What are the key responsibilities of a decorative cutting machine tender?

The key responsibilities of a decorative cutting machine tender generally include:

Loading and unloading materials:

- Selecting and loading the appropriate materials into the machine.

- Unloading the finished products and inspecting them for quality.

Operating the machine:

- Setting up the machine according to the specified cutting parameters.

- Monitoring the machine during operation to ensure proper functioning.

- Troubleshooting and resolving any issues that may arise.

Maintenance and cleaning:

- Performing regular maintenance and cleaning tasks to ensure the machine’s optimal performance.

- Following established safety protocols to minimize risks and accidents.

3. What are the different types of decorative cutting machines?

There are several types of decorative cutting machines, each with its unique capabilities:

- Laser cutting machines: Utilize a focused laser beam to cut precise and intricate designs on various materials.

- Waterjet cutting machines: Employ a high-pressure water jet to cut through thick and hard materials with high accuracy.

- Plasma cutting machines: Use a plasma torch to cut metal materials, offering high speed and precision.

- Die cutting machines: Utilize sharp dies to cut materials into specific shapes and sizes.

- CNC cutting machines: Computer-controlled machines that offer automated cutting based on digital designs.

4. How do you ensure the accuracy and precision of decorative cutting operations?

To ensure accuracy and precision in decorative cutting operations, I follow these steps:

- Proper machine setup: Setting up the machine according to the specified cutting parameters, including material type, thickness, and design specifications.

- Material handling: Ensuring that the materials are correctly loaded and aligned within the machine to minimize errors.

- Regular calibration and maintenance: Performing regular calibration and maintenance procedures to maintain the machine’s precision and minimize deviations.

- Quality control: Conducting thorough inspections of the finished products to identify and rectify any inaccuracies or imperfections.

5. What safety measures should be observed when operating a decorative cutting machine?

When operating a decorative cutting machine, the following safety measures are paramount:

- Protective gear: Wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs, to minimize risks.

- Machine guarding: Ensuring that all machine guards are in place and functioning correctly to prevent contact with moving parts.

- Proper training and authorization: Only trained and authorized personnel should operate the machine.

- Emergency procedures: Familiarizing oneself with emergency procedures and knowing how to respond to potential hazards.

- Regular risk assessments: Conducting regular risk assessments to identify and mitigate potential safety concerns.

6. How do you handle waste materials generated from decorative cutting operations?

Managing waste materials from decorative cutting operations is crucial for environmental sustainability:

- Waste segregation: Segregating waste materials based on their type and composition, such as metal, plastic, and paper.

- Recycling programs: Implementing recycling programs to divert recyclable materials from landfills.

- Waste minimization techniques: Exploring ways to minimize waste generation through efficient material utilization and process optimization.

- Vendor partnerships: Collaborating with vendors who offer waste management and disposal services.

7. What is your experience in working with different materials on a decorative cutting machine?

Throughout my career, I have gained extensive experience in working with various materials on decorative cutting machines:

- Metals: Stainless steel, aluminum, copper, and brass for intricate designs and high-precision applications.

- Wood: Plywood, MDF, and hardwoods for furniture components, decorative panels, and signage.

- Plastics: Acrylic, PVC, and polycarbonate for lightweight and durable products such as signage, display stands, and automotive parts.

- Textiles: Leather, fabric, and vinyl for applications in fashion, upholstery, and interior design.

8. How do you ensure the efficiency and productivity of decorative cutting operations?

To optimize efficiency and productivity in decorative cutting operations, I implement the following strategies:

- Process optimization: Analyzing and streamlining cutting processes to minimize production time and waste.

- Preventive maintenance: Regularly servicing and maintaining the machine to prevent breakdowns and ensure smooth operation.

- Operator training: Providing comprehensive training to operators to enhance their skills and maximize machine utilization.

- Production planning: Scheduling cutting jobs efficiently to optimize machine capacity and minimize downtime.

9. What software programs are you familiar with for decorative cutting machine operations?

In my experience, I have become proficient in utilizing various software programs essential for decorative cutting machine operations:

- CAD/CAM software: Designing and generating cutting paths for complex designs using computer-aided design (CAD) and computer-aided manufacturing (CAM) software.

- Machine control software: Operating and controlling the cutting machine through dedicated software interfaces.

- Visualization and simulation software: Simulating cutting operations to optimize parameters and prevent errors.

- Production management software: Managing cutting jobs, scheduling, and tracking production progress.

10. How do you stay updated with the latest advancements in decorative cutting technologies?

To stay current with the evolving landscape of decorative cutting technologies, I actively engage in the following practices:

- Industry events and conferences: Attending industry events and conferences to learn about new technologies, innovations, and best practices.

- Trade publications and online resources: Regularly reading industry publications, visiting websites, and engaging in online forums to stay informed.

- Collaboration with suppliers and vendors: Partnering with suppliers and vendors to gain insights into their latest product offerings and technological advancements.

- Continuing education and training: Participating in workshops, webinars, and training programs to enhance my knowledge and skills in this rapidly evolving field.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Decorative Cutting Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Decorative Cutting Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Decorative Cutting Machine Tender plays a pivotal role in the production process, utilizing advanced cutting machinery to create intricate designs and shapes on various materials.

1. Machine Operation and Setup

Skilled in operating a range of decorative cutting machines, including laser cutters, waterjets, and plasma cutters.

- Expertly setting up and calibrating machines based on specific design requirements and material properties.

- Monitoring and adjusting machine parameters to ensure optimal performance and precision cutting.

2. Material Handling and Preparation

Demonstrates proficiency in handling and preparing a variety of materials, including metals, plastics, wood, and fabrics.

- Inspecting materials for defects and ensuring they meet quality standards before cutting.

- Properly loading and unloading materials into and out of the cutting machine.

3. Quality Control and Inspection

Maintains a meticulous approach to quality control, ensuring that all cut pieces meet specifications.

- Inspecting cut pieces for accuracy, dimensions, and finish.

- Identifying and resolving any discrepancies or defects to maintain the highest quality standards.

4. Maintenance and Troubleshooting

Proficient in performing basic maintenance and troubleshooting tasks to ensure machine efficiency and prevent downtime.

- Cleaning and lubricating machines regularly to maintain optimal performance.

- Troubleshoot minor issues and perform necessary repairs to minimize disruptions to production.

Interview Tips

To ace the interview for the Decorative Cutting Machine Tender position, it is crucial to prepare effectively and showcase your relevant skills and experience.

1. Research the Company and Industry

Thoroughly research the company’s profile, products, and industry trends to demonstrate your interest and understanding of the role.

- Visit the company’s website, read industry publications, and attend webinars to gather insights.

- Prepare specific examples of how your skills and experience align with the company’s needs.

2. Practice Common Interview Questions

Anticipate common interview questions and prepare thoughtful and concise answers that highlight your strengths.

- Explain your experience with decorative cutting machines and specific examples of successful projects.

- Describe your approach to quality control and how you ensure accuracy and precision in your work.

3. Emphasize Your Technical Skills

Showcase your technical proficiency in operating and maintaining decorative cutting machines.

- Provide specific details about the types of machines you have operated and the materials you have cut.

- Highlight your knowledge of cutting parameters and how you optimize them for different materials and designs.

4. Highlight Your Problem-Solving Abilities

Emphasize your ability to troubleshoot and resolve issues with cutting machines.

- Share examples of how you identified and fixed problems that arose during production.

- Explain your approach to problem-solving and how you prioritize tasks to ensure efficient resolution.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Decorative Cutting Machine Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!