Are you gearing up for a career in Deicer Finisher? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Deicer Finisher and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

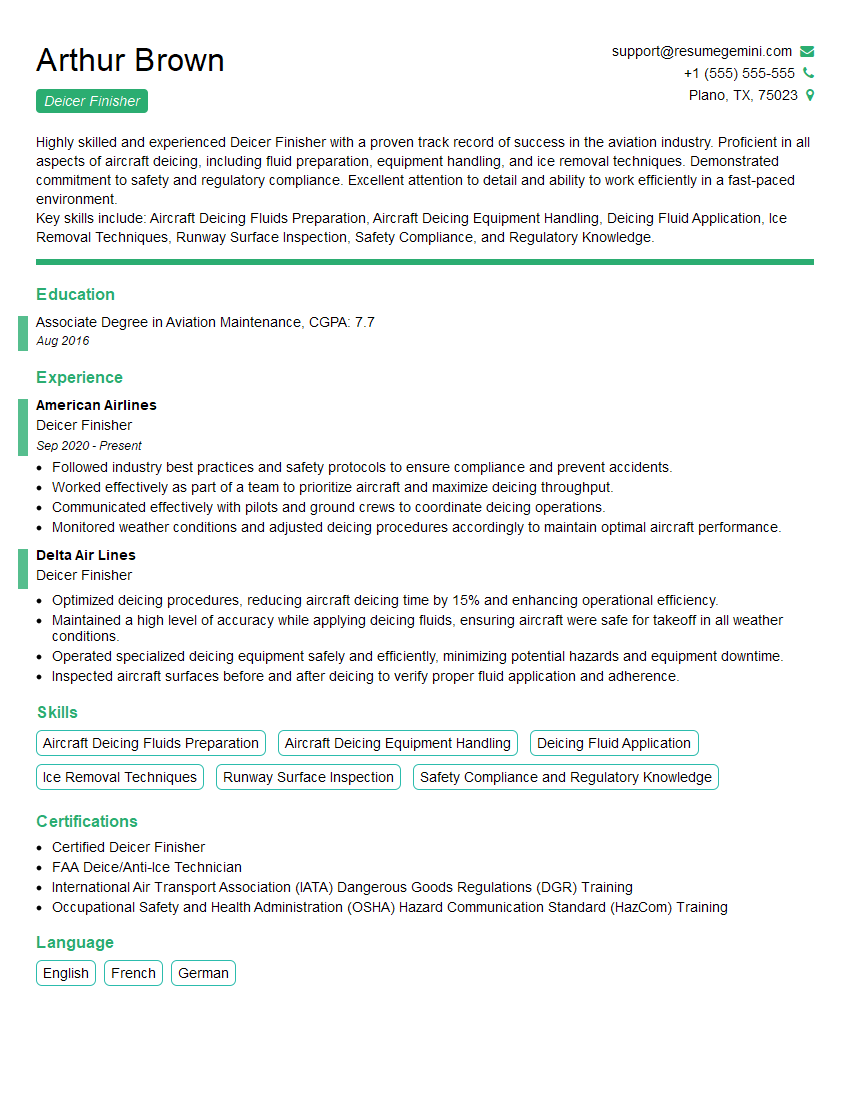

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Deicer Finisher

1. What are the different types of deicing fluids used in aircraft maintenance, and what are the safety precautions required when handling them?

- There are three main types of deicing fluids: Type I, Type II, and Type IV.

- Type I is a newtonian fluid and is made up of a mixture of ethylene glycol and water, and is effective down to -34°C.

- Type II is a pseudoplastic fluid and is made up of a mixture of ethylene glycol, propylene glycol, and water, and is effective down to -50°C.

- Type IV is a thickened fluid that has a higher viscosity than Type I and Type II, and is made up of a mixture of ethylene glycol, propylene glycol, and thickeners, and is effective down to -60°C.

- When handling deicing fluids, it is important to wear appropriate personal protective equipment, such as gloves, goggles, and a respirator.

- It is also important to avoid contact with skin and eyes, and to avoid inhaling the fumes.

- Deicing fluids can be harmful if ingested, so it is important to keep them away from children and pets.

2. What are the steps involved in the deicing process?

Step 1: Inspection

- Inspect the aircraft for any ice or snow accumulation.

- Identify the areas that need to be deiced, such as the wings, tail, and fuselage.

Step 2: Preparation

- Gather the necessary equipment and materials, such as deicing fluid, a deicing wand, and a scraper.

- Set up the deicing equipment and ensure that it is working properly.

Step 3: Application

- Apply the deicing fluid to the areas that need to be deiced.

- Use a deicing wand to spray the fluid evenly over the surface.

- Allow the fluid to dwell for the recommended amount of time.

Step 4: Removal

- Use a scraper to remove any remaining ice or snow.

- Use a clean cloth to wipe down the surface and remove any residual fluid.

Step 5: Inspection

- Inspect the aircraft to ensure that all ice and snow has been removed.

- Repeat the deicing process if necessary.

3. What are the different methods of deicing aircraft?

- There are two main methods of deicing aircraft: ground deicing and aerial deicing.

- Ground deicing is performed on the ground before takeoff.

- Aerial deicing is performed in the air while the aircraft is flying.

- Ground deicing is typically performed using deicing fluid.

- Aerial deicing is typically performed using heated air or infrared radiation.

4. What are the advantages and disadvantages of using deicing fluid?

Advantages

- Deicing fluid is effective at removing ice and snow from aircraft.

- Deicing fluid is relatively inexpensive.

- Deicing fluid is easy to apply.

Disadvantages

- Deicing fluid can be harmful to the environment.

- Deicing fluid can be corrosive to aircraft.

- Deicing fluid can be a fire hazard.

5. What are the different types of deicing equipment?

- There are a variety of deicing equipment available, including deicing trucks, deicing wands, and deicing platforms.

- Deicing trucks are used to apply deicing fluid to aircraft.

- Deicing wands are used to spray deicing fluid onto aircraft.

- Deicing platforms are used to elevate aircraft so that they can be deiced more easily.

6. What are the safety precautions that must be taken when using deicing equipment?

- When using deicing equipment, it is important to wear appropriate personal protective equipment, such as gloves, goggles, and a respirator.

- It is also important to avoid contact with skin and eyes, and to avoid inhaling the fumes.

- Deicing equipment can be dangerous if it is not used properly, so it is important to follow the manufacturer’s instructions.

7. What are the different types of deicing fluids?

- There are three main types of deicing fluids: Type I, Type II, and Type IV.

- Type I deicing fluid is a newtonian fluid and is made up of a mixture of ethylene glycol and water.

- Type II deicing fluid is a pseudoplastic fluid and is made up of a mixture of ethylene glycol, propylene glycol, and water.

- Type IV deicing fluid is a thickened fluid that has a higher viscosity than Type I and Type II deicing fluids, and is made up of a mixture of ethylene glycol, propylene glycol, and thickeners.

8. What are the factors that affect the effectiveness of deicing fluids?

- The effectiveness of deicing fluids is affected by a number of factors, including the temperature, the type of ice or snow, and the application method.

- Deicing fluids are most effective when they are applied at the correct temperature.

- Deicing fluids are more effective at removing ice than snow.

- Deicing fluids are more effective when they are applied using a spray nozzle than a brush.

9. What are the environmental concerns associated with the use of deicing fluids?

- The use of deicing fluids can have a number of environmental concerns, including the contamination of water sources and the release of harmful chemicals into the air.

- Deicing fluids can contain harmful chemicals, such as ethylene glycol and propylene glycol.

- Deicing fluids can contaminate water sources if they are not properly disposed of.

- Deicing fluids can release harmful chemicals into the air when they are applied to aircraft.

10. What are the future trends in deicing technology?

- There are a number of future trends in deicing technology, including the development of more environmentally friendly deicing fluids and the use of new deicing methods.

- Researchers are developing new deicing fluids that are less harmful to the environment.

- Researchers are also developing new deicing methods, such as the use of lasers and infrared radiation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Deicer Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Deicer Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Deicer Finisher plays a vital role in ensuring aircraft safety and on-time departures during winter operations. Their primary responsibilities include:

1. Deicing and Anti-Icing Aircraft

Apply deicing or anti-icing fluids to aircraft surfaces according to established procedures and industry standards to prevent ice and snow accumulation.

- Operate deicing/anti-icing equipment safely and efficiently.

- Monitor weather conditions and adjust deicing/anti-icing procedures as needed.

2. Inspecting Aircraft Surfaces

Conduct thorough pre- and post-deicing/anti-icing inspections to ensure that aircraft surfaces are free of ice, snow, and contaminants.

- Identify any areas that require additional attention or treatment.

- Follow established inspection protocols and document findings accurately.

3. Communicating with Pilots and Ground Crew

Effectively communicate with pilots and ground crew to ensure a coordinated and safe deicing/anti-icing process.

- Provide pilots with accurate information on deicing/anti-icing procedures and aircraft condition.

- Coordinate with ground crew to ensure proper equipment setup and fluid management.

4. Maintaining Equipment and Facilities

Keep deicing/anti-icing equipment in good working order through regular maintenance and inspections.

- Identify and report any equipment issues promptly.

- Follow established safety protocols and environmental guidelines.

Interview Tips

To ace your Deicer Finisher interview, consider the following tips:

1. Research the Company and Industry

Demonstrate your interest in the specific company and the aviation industry. Research their operations, safety record, and commitment to customer service.

- Visit the company website and social media pages.

- Read industry news and articles to stay informed about best practices and regulations.

2. Highlight Your Deicing Experience and Skills

Emphasize your experience in aircraft deicing and anti-icing procedures. Quantify your accomplishments and provide specific examples of your attention to detail and commitment to safety.

- Describe your experience using different types of deicing/anti-icing equipment.

- Discuss your knowledge of weather conditions and how they affect deicing/anti-icing operations.

3. Demonstrate Teamwork and Communication Skills

Deicer Finishers work closely with other team members, including pilots and ground crew. Highlight your ability to communicate effectively and work collaboratively in a fast-paced environment.

- Share examples of how you have effectively communicated with team members to ensure a smooth deicing process.

- Explain how you prioritize tasks and delegate responsibilities to maximize efficiency.

4. Prepare for Behavioral Interview Questions

Behavioral interview questions assess your past performance and suitability for the role. Prepare for common questions such as:

- Tell me about a time you faced a challenging weather condition during deicing operations.

- Describe a situation where you had to prioritize multiple tasks and make quick decisions.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Deicer Finisher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!