Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Die Stamper interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Die Stamper so you can tailor your answers to impress potential employers.

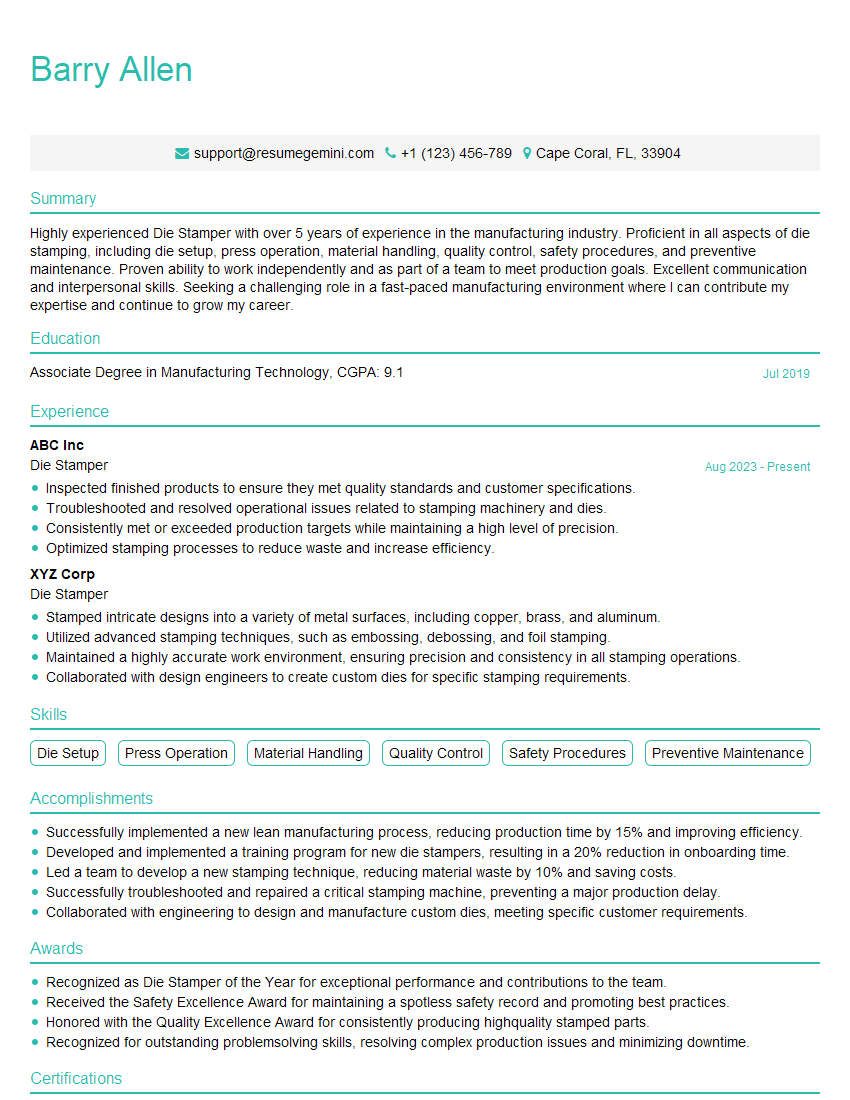

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Die Stamper

1. Describe the process of preparing a die for stamping?

- Inspect the die for any damage or wear.

- Clean the die using a solvent and a brush.

- Apply a lubricant to the die.

- Install the die in the stamping press.

- Adjust the press settings according to the die specifications.

2. What are the different types of stamping dies?

Progressive dies:

- Used for producing complex parts.

- Consist of a series of stations that perform different operations on the workpiece.

Compound dies:

- Used for producing parts that require multiple operations.

- Consist of two or more dies that are mounted in the same press.

Transfer dies:

- Used for producing parts that require precise placement.

- Transfer the workpiece from one station to another using a slide or a gripper.

3. What are the factors that affect the quality of stamped parts?

Die design:

- The design of the die affects the accuracy, precision, and quality of the stamped parts.

- Factors such as die clearance, die angle, and die material must be carefully considered.

Material properties:

- The properties of the workpiece material affect the stamping process.

- Factors such as thickness, hardness, and ductility must be taken into account.

Press conditions:

- The operating conditions of the stamping press affect the quality of the stamped parts.

- Factors such as press speed, pressure, and dwell time must be optimized.

4. What are the common defects in stamped parts and how can they be prevented?

Burrs:

- Caused by excessive material being pushed out of the die.

- Can be prevented by using sharp dies, proper die clearance, and lubrication.

Wrinkles:

- Caused by the material being stretched too much during the stamping process.

- Can be prevented by using dies with a proper radius and by reducing the draw depth.

Cracks:

- Caused by excessive stress or brittle material.

- Can be prevented by using ductile materials, reducing the draw depth, and annealing the material.

5. How do you maintain and troubleshoot stamping dies?

- Inspect dies regularly for wear and damage.

- Clean and lubricate dies as needed.

- Adjust die settings according to the manufacturer’s specifications.

- Troubleshoot problems by analyzing the stamped parts and identifying the cause of the defect.

6. What are the safety precautions that must be taken when operating a stamping press?

- Wear appropriate safety gear, including gloves, eye protection, and hearing protection.

- Keep hands out of the die area while the press is operating.

- Follow lockout/tagout procedures when performing maintenance on the press.

- Be aware of potential hazards, such as flying debris and pinch points.

7. What are the latest trends in stamping technology?

- High-speed stamping: Uses advanced press technology to achieve faster cycle times.

- Servo stamping: Uses servo motors to control the movement of the press slide, providing greater precision and control.

- Transfer stamping: Uses robots or automated systems to transfer workpieces between stamping stations.

- Laser cutting: Uses lasers to cut complex shapes into metal sheets, eliminating the need for dies.

8. What are the challenges and opportunities in the stamping industry?

Challenges:

- Increasing demand for lightweight and high-strength materials.

- Need for improved productivity and efficiency.

- Environmental regulations and sustainability concerns.

Opportunities:

- Development of new materials and technologies.

- Growing demand for stamped parts in industries such as automotive, aerospace, and electronics.

- Potential for automation and process optimization.

9. How do you stay up-to-date on the latest stamping technology and best practices?

- Attend industry conferences and exhibitions.

- Read trade publications and technical journals.

- Participate in online forums and discussion groups.

- Network with other stamping professionals.

10. Why do you think you are the best candidate for this position?

- I have extensive experience in die stamping, including die design, die maintenance, and troubleshooting.

- I have a strong understanding of the principles of stamping technology and the factors that affect the quality of stamped parts.

- I am proficient in operating various types of stamping presses and dies.

- I am committed to safety and quality, and I am always looking for ways to improve my skills and knowledge.

- I am confident that I can contribute to the success of your company by providing high-quality stamped parts and excellent customer service.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Die Stamper.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Die Stamper‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Die Stampers are responsible for operating stamping machines to produce metal parts and components. Key job responsibilities include:

1. Machine Operation

Setting up and operating stamping machines to produce metal parts and components.

- Selecting and installing dies.

- Feeding metal into the machine.

- Monitoring the stamping process.

- Adjusting machine settings to ensure quality production.

2. Die Maintenance

Inspecting, cleaning, and maintaining dies and stamping equipment.

- Sharpening dies.

- Replacing worn or damaged parts.

- Lubricating equipment.

3. Quality Control

Inspecting finished parts to ensure they meet specifications.

- Measuring parts using calipers or micrometers.

- Identifying and correcting defects.

4. Safety

Following safety procedures to prevent accidents and injuries.

- Wearing appropriate safety gear.

- Operating machinery safely.

- Maintaining a clean and organized work area.

Interview Tips

To ace your interview for a Die Stamper position, consider the following tips:

1. Research the Company and Position

Learn about the company’s history, products, and industry. Research the specific Die Stamper position and its responsibilities.

- Visit the company’s website.

- Read industry publications.

- Talk to people in your network who may have knowledge of the company or position.

2. Practice Your Answers

Prepare for common interview questions and practice your answers. This will help you feel more confident and articulate during the interview.

- Review the job description and identify key skills and experiences.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Ask a friend or family member to conduct a mock interview.

3. Showcase Your Experience

Highlight your relevant experience and skills that make you a suitable candidate for the Die Stamper position.

- Quantify your accomplishments with specific numbers and metrics.

- Use action verbs to describe your responsibilities and achievements.

- Be prepared to discuss your experience with die stamping equipment, quality control, and safety procedures.

4. Ask Questions

Asking thoughtful questions shows that you’re engaged and interested in the position. It also gives you an opportunity to gather more information about the company and the role.

- Ask about the company’s culture and values.

- Inquire about opportunities for professional development and advancement.

- Ask about the specific challenges and responsibilities of the Die Stamper position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Die Stamper interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!