Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Dieing Out Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

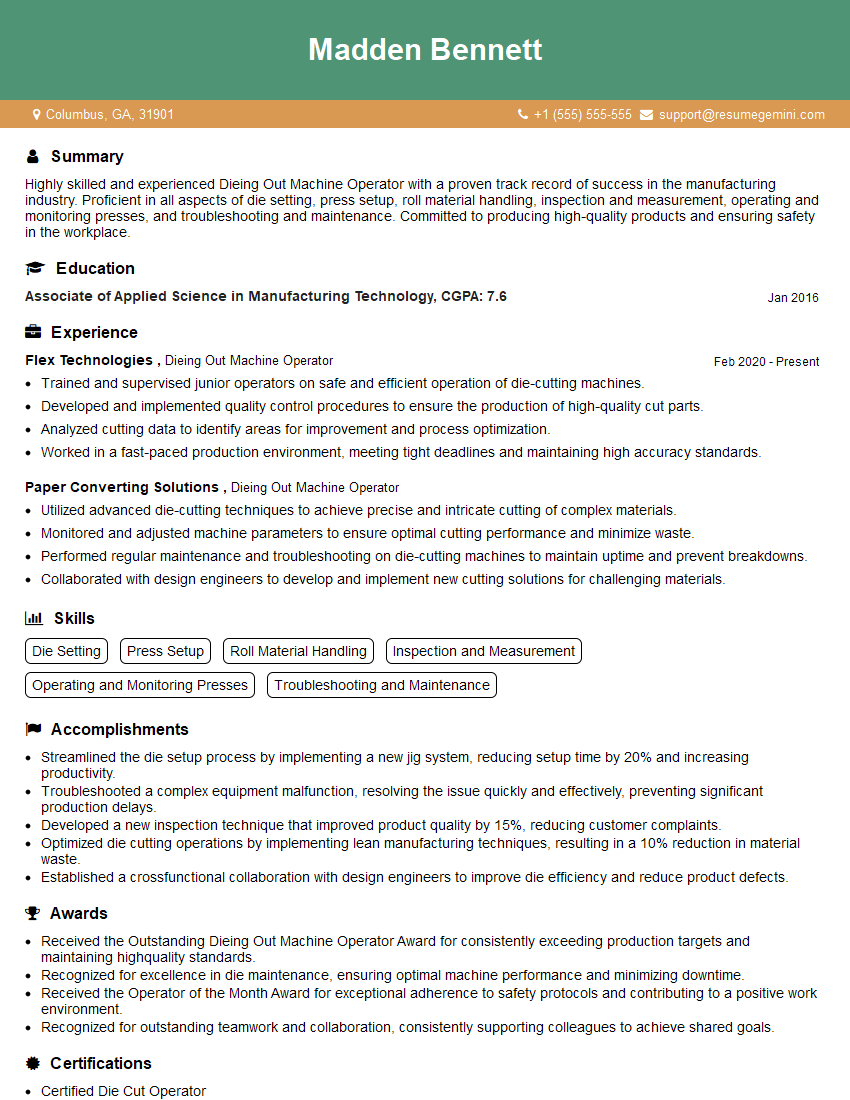

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dieing Out Machine Operator

1. Explain the process of operating a dieing out machine?

The process of operating a dieing out machine involves several key steps:

- Loading the machine: Load the die into the machine, ensuring it is properly aligned and secured.

- Setting up the machine: Adjust the machine’s settings, including pressure, dwell time, and stroke length, based on the material and die specifications.

- Positioning the material: Place the material on the die surface, taking care to align it correctly.

- Activating the machine: Initiate the cutting cycle, either manually or automatically, depending on the machine’s design.

- Monitoring the process: Observe the cutting process, ensuring that the material is cut accurately and cleanly.

- Removing the finished product: Once the cutting cycle is complete, remove the finished product from the machine.

2. What are the different types of dieing out machines and their applications?

- Flatbed dieing out machine: Used for cutting flat materials, such as sheet metal, plastic, and rubber.

- Rotary dieing out machine: Employs a rotating cutting head to cut continuous materials, such as textiles and films.

- Semi-rotary dieing out machine: Combines features of flatbed and rotary machines, allowing for both flat and curved cutting.

- Laser dieing out machine: Utilizes a laser beam to cut materials, providing high precision and intricate cuts.

3. How do you ensure the accuracy and precision of the dieing out process?

- Proper die alignment: Check and adjust the die alignment regularly to ensure accurate cutting.

- Precise machine settings: Calibrate the machine’s pressure, dwell time, and stroke length to optimize cutting results.

- Material quality control: Inspect the material before cutting to ensure it meets specifications and is free from defects.

- Regular maintenance and calibration: Perform routine maintenance and calibration to maintain machine accuracy.

4. How do you troubleshoot common problems encountered while operating a dieing out machine?

- Poor cutting quality: Check die sharpness, machine settings, and material properties.

- Material damage: Inspect the material for defects, adjust machine settings, or replace the die.

- Machine malfunction: Check for electrical or mechanical issues, consult the machine manual, and seek professional assistance if necessary.

5. What are the safety precautions to consider when operating a dieing out machine?

- Wear appropriate safety gear: Including gloves, eye protection, and ear protection.

- Keep the work area clean and organized: To prevent tripping hazards and material damage.

- Follow proper operating procedures: As outlined in the machine’s manual and company policies.

- Be aware of pinch points and sharp edges: To avoid injuries.

- Never reach into the machine while it is operating: To prevent accidents.

6. How do you maintain and care for a dieing out machine?

- Regular cleaning: Remove debris and dust from the machine’s components.

- Lubrication: Apply lubricants to moving parts to reduce friction and wear.

- Die maintenance: Sharpen or replace dies as needed to ensure cutting accuracy.

- Electrical and mechanical checks: Inspect electrical connections and mechanical components for any loose or damaged parts.

- Keep a maintenance log: Document maintenance activities and any issues encountered.

7. What is the difference between a dieing out machine and a punching machine?

- Purpose: Dieing out machines are primarily used for cutting materials, while punching machines are designed to create holes or shapes in materials.

- Die type: Dieing out machines use flat dies, while punching machines use punches and dies.

- Process: Dieing out machines cut the entire shape from the material, while punching machines remove material from the inside of a shape.

8. How do you handle variations in material thickness when using a dieing out machine?

- Adjust machine settings: Modify the pressure and stroke length to accommodate different material thicknesses.

- Use spacer materials: Place spacers beneath thinner materials to achieve the desired cutting depth.

- Calibrate the machine: Ensure that the machine’s settings are optimized for the specific material and thickness being used.

9. What is the importance of dwell time in the dieing out process?

- Material penetration: Dwell time allows the cutting die to fully penetrate the material, ensuring a clean and precise cut.

- Stress relief: It provides time for the material to recover from the cutting force, reducing stress and preventing material damage.

- Optimization: Proper dwell time optimizes the cutting process, reducing cycle time and improving product quality.

10. Can you describe the different types of dies used in dieing out machines?

- Solid dies: Made from a single piece of material, solid dies provide high cutting force and are suitable for high-volume production.

- Composite dies: Combine different materials, such as steel and rubber, to reduce wear and tear and extend die life.

- Progressive dies: Perform multiple cutting operations in a single stroke, increasing efficiency and reducing production time.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dieing Out Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dieing Out Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dieing out machine operators are responsible for operating dieing out machines to cut complex shapes from various materials. They must ensure that the machine is set up and operating properly, and that the materials are cut to the correct dimensions and specifications. Some of the key job responsibilities include:

1. Set up and operate dieing out machines

Dieing out machine operators must be able to set up and operate dieing out machines safely and efficiently. This involves:

Positioning and securing the material to be cut

Adjusting the machine settings to ensure that the material is cut to the correct dimensions and specifications

Monitoring the machine while it is in operation

2. Inspect cut materials

Dieing out machine operators must inspect the cut materials to ensure that they meet the required specifications. This involves:

Checking the dimensions of the cut materials

Inspecting the cut materials for any defects

Rejecting any cut materials that do not meet the required specifications

3. Maintain dieing out machines

Dieing out machine operators must maintain dieing out machines to ensure that they are in good working order. This involves:

Cleaning and lubricating the machine

Inspecting the machine for any worn or damaged parts

Replacing any worn or damaged parts

4. Troubleshoot machine problems

Dieing out machine operators must be able to troubleshoot machine problems. This involves:

Identifying the source of the problem

Taking steps to resolve the problem

Calling for assistance if necessary

Interview Tips

To ace the interview for a Dieing Out Machine Operator position, it is important to be prepared and to highlight your skills and experience. Here are some tips to help you prepare for the interview:

1. Research the company and the position

This will give you a good understanding of the company’s culture and the specific requirements of the position. You can find information about the company on their website and social media pages. You can also find information about the position in the job description.

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is important to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

3. Be prepared to talk about your skills and experience

The interviewer will want to know about your skills and experience in operating dieing out machines. Be prepared to discuss your experience in setting up and operating dieing out machines, inspecting cut materials, maintaining dieing out machines, and troubleshooting machine problems.

4. Be prepared to ask questions

Asking questions at the end of the interview shows that you are interested in the position and that you are engaged in the conversation. It is also a good way to get more information about the company and the position.

5. Dress professionally and arrive on time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This will show the interviewer that you are serious about the position and that you are respectful of their time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dieing Out Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.