Are you gearing up for a career in Diesel Engine Pipe Fitter? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Diesel Engine Pipe Fitter and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

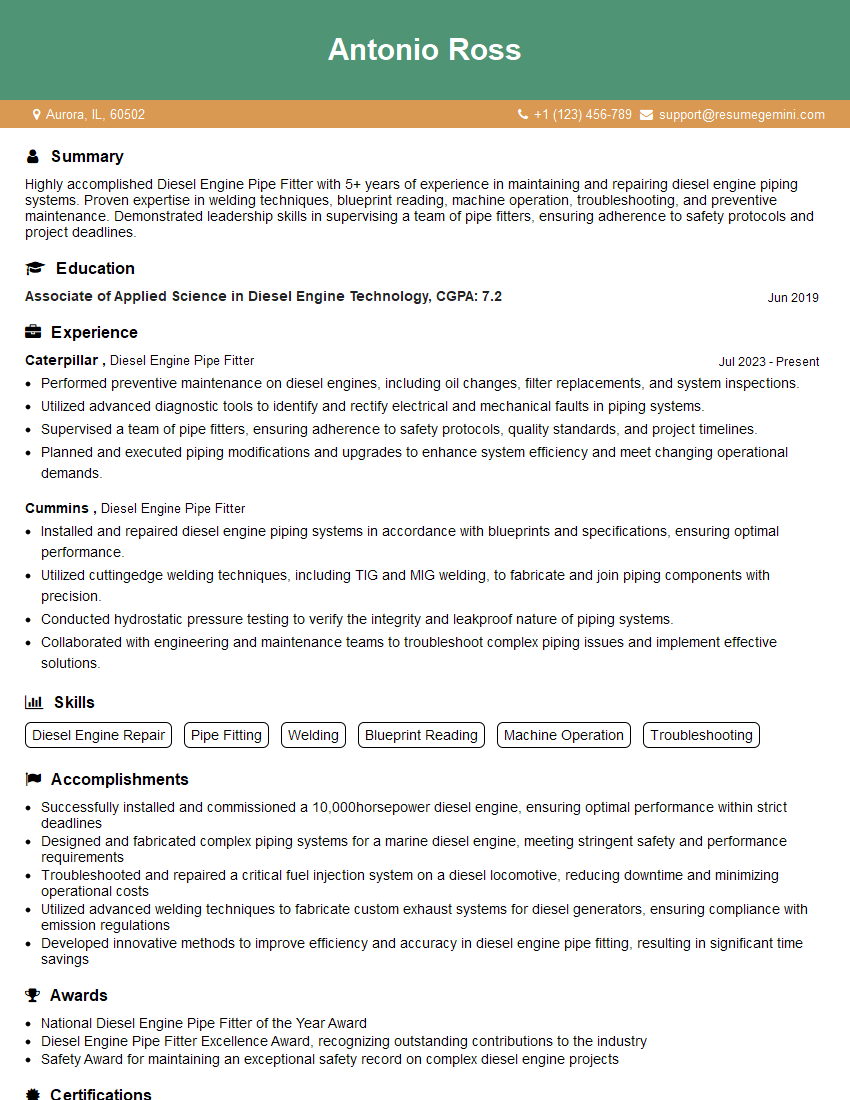

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Diesel Engine Pipe Fitter

1. What are the different types of diesel engine pipe fittings?

There are various types of diesel engine pipe fittings, including:

- Elbows

- Tees

- Couplings

- Reducers

- Flanges

- Valves

- Filters

2. What are the safety precautions that must be taken when working with diesel engine pipe fittings?

Wearing appropriate PPE

- Safety glasses

- Gloves

- Coveralls

- Safety shoes

Using proper tools and equipment

- Pipe wrenches

- Thread sealant

- Leak detectors

3. How do you inspect diesel engine pipe fittings for leaks?

Diesel engine pipe fittings can be inspected for leaks using several methods:

- Visual inspection

- Leak detection spray

- Pressure testing

- Ultrasonic testing

4. How do you troubleshoot common problems with diesel engine pipe fittings?

Common problems with diesel engine pipe fittings include:

- Leaks

- Clogs

- Corrosion

- Vibration

Troubleshooting involves:

- Identifying the problem

- Determining the cause

- Implementing a solution

5. How do you maintain diesel engine pipe fittings?

Diesel engine pipe fittings require regular maintenance to ensure proper operation and prevent problems:

- Inspection

- Cleaning

- Lubrication

- Tightening

- Replacement

6. What are the different types of materials used in diesel engine pipe fittings?

Diesel engine pipe fittings are made from various materials, including:

- Steel

- Stainless steel

- Copper

- Brass

- Aluminum

- Plastic

7. What is the difference between a pipe fitting and a pipe flange?

Pipe fitting

- Connects pipes and tubes

- Types: elbows, tees, couplings

- Threaded or welded

Pipe flange

- Connects pipes to other components

- Types: raised face, flat face, blind

- Bolted together

8. What are the different types of welding used in diesel engine pipe fitting?

Diesel engine pipe fitting involves various welding techniques:

- Gas tungsten arc welding (GTAW)

- Gas metal arc welding (GMAW)

- Shielded metal arc welding (SMAW)

- Flux-cored arc welding (FCAW)

9. What are the challenges of working with diesel engine pipe fittings?

Working with diesel engine pipe fittings poses certain challenges:

- Confined spaces

- High temperatures

- Hazardous materials

- Meeting industry standards

10. What are the latest trends in diesel engine pipe fitting?

The diesel engine pipe fitting industry is constantly evolving:

- Increased use of advanced materials

- Adoption of automated welding techniques

- Focus on environmental sustainability

- Integration of digital technologies

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Diesel Engine Pipe Fitter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Diesel Engine Pipe Fitter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Diesel Engine Pipe Fitter, you will be responsible for a wide range of tasks related to the installation, maintenance, and repair of diesel engines. Your core duties will include:

1. Pipe Fitting

Install, repair, and modify piping systems to ensure that fuel, oil, and other fluids flow correctly through the engine. Interpret blueprints and diagrams to determine pipe layout and specifications.

- Cut, bend, and weld pipes to fit engine specifications.

- Test and inspect piping systems for leaks and proper operation.

2. Engine Assembly and Disassembly

Work with mechanics to assemble and disassemble diesel engines. Follow technical manuals and procedures to ensure proper installation and alignment of components.

- Install gaskets, seals, and other components.

- Adjust and calibrate engine components to meet performance specifications.

3. Troubleshooting and Repair

Diagnose and repair issues with diesel engines. Use diagnostic tools and test equipment to identify and fix problems with fuel systems, lubrication systems, and other engine components.

- Perform maintenance and repairs on diesel engines and their components.

- Ensure that engines meet safety and performance standards.

4. Safety and Compliance

Follow all safety protocols and procedures. Wear appropriate personal protective equipment (PPE) and maintain a clean and organized work area. Comply with environmental regulations and industry standards.

- Follow company safety policies and procedures.

- Report any safety hazards or concerns.

Interview Tips

To ace your interview for a Diesel Engine Pipe Fitter position, consider the following tips:

1. Research the Company and Industry

Familiarize yourself with the company’s operations, products, and industry trends. Demonstrate your understanding of diesel engine technology and the specific requirements of the position.

- Visit the company website and read industry publications.

- Prepare questions that show your interest in the company and the role.

2. Highlight Your Skills and Experience

Emphasize your technical skills, including pipe fitting, engine assembly, and troubleshooting. Provide specific examples of your accomplishments that demonstrate your proficiency in these areas.

- Quantify your achievements with specific metrics, such as time saved or efficiency improvements.

- Use the STAR method to structure your answers: Situation, Task, Action, Result.

3. Demonstrate Your Safety Awareness

In this role, safety is of utmost importance. Highlight your adherence to safety protocols and your experience in maintaining a safe work environment.

- Provide examples of how you have followed safety procedures in past roles.

- Explain your understanding of the importance of adhering to safety guidelines.

4. Be Enthusiastic and Professional

Conveying your enthusiasm for diesel engine pipe fitting will positively impact your chances of success. Display a positive attitude and demonstrate your eagerness to contribute to the team.

- Be prepared to talk about your career aspirations and how this role aligns with them.

- Dress professionally and arrive on time for your interview.

Next Step:

Now that you’re armed with the knowledge of Diesel Engine Pipe Fitter interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Diesel Engine Pipe Fitter positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini