Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Digging Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

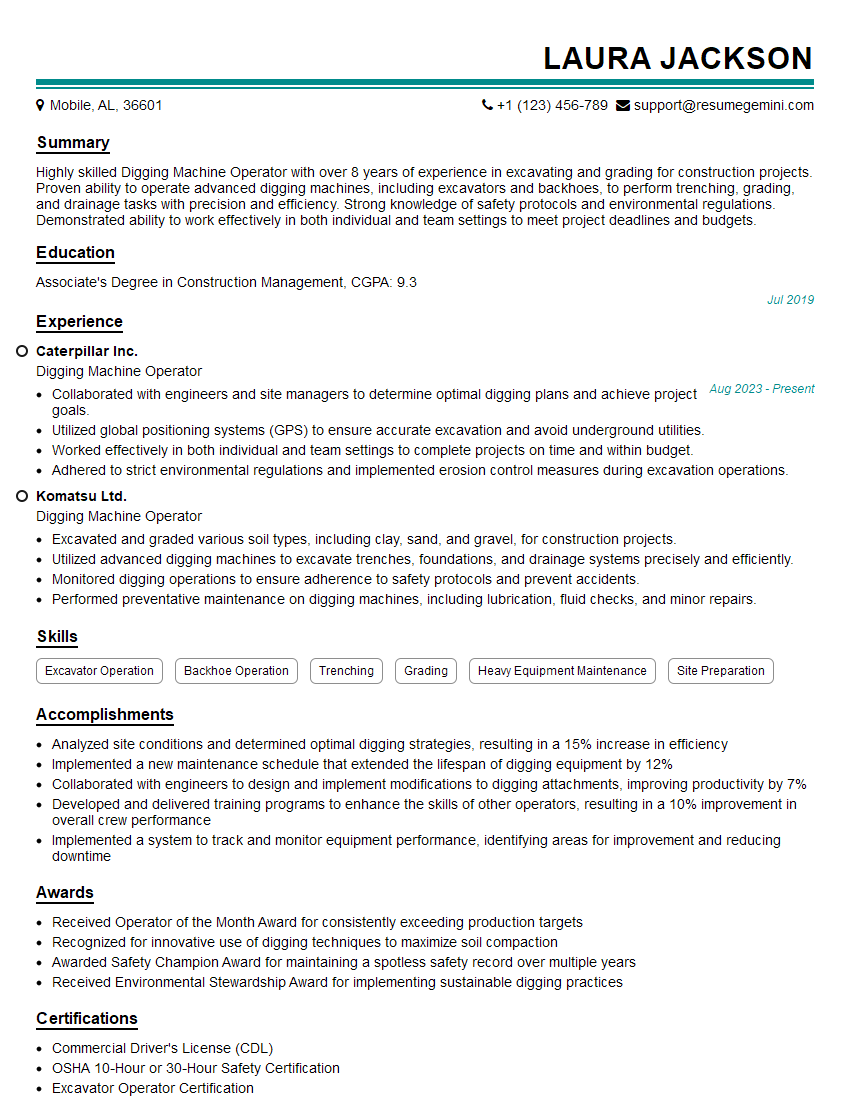

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Digging Machine Operator

1. What are the critical safety precautions you observe when operating a digging machine?

- Conduct daily inspections to ensure the equipment is in good working order.

- Wear appropriate safety gear, including a hard hat, safety glasses, and work boots.

- Stay away from overhead power lines.

- Be aware of your surroundings and keep others at a safe distance.

- Never operate the machine under the influence of drugs or alcohol.

2. Describe the different types of digging machine attachments and their applications?

Buckets

- General-purpose buckets: digging, trenching, and backfilling.

- Rock buckets: designed for heavy-duty excavation.

- Clay buckets: effective for digging in sticky or wet soils.

Augers

- Used for drilling holes for foundations, poles, and fencing.

- Come in various sizes and shapes to accommodate different bore diameters.

3. How do you determine the appropriate digging depth and angle for a specific excavation project?

- Review project plans and specifications.

- Inspect the soil conditions to determine soil density and moisture content.

- Consider the weight and stability of the digging machine.

- Adjust the digging angle and depth accordingly to achieve the desired results and avoid over-excavation.

4. Describe the maintenance and troubleshooting procedures you follow to keep the digging machine in good working condition?

- Regular inspections: checking oil levels, filters, and hydraulics.

- Lubrication: greasing and oiling moving parts.

- Troubleshooting: identifying and addressing minor issues before they become major problems.

- Following manufacturer’s recommended maintenance schedule.

- Keeping a maintenance log to track repairs and replacements.

5. Have you ever operated a digging machine in confined spaces or near underground utilities? If so, how did you ensure safety and avoid damage?

- Obtained permits and followed all safety regulations.

- Used hand digging or vacuum excavation to expose and protect utilities.

- Communicated clearly with utility companies and followed their guidelines.

- Worked carefully and cautiously to minimize risks and prevent damage.

6. How do you handle challenging ground conditions, such as rocky soil or waterlogged areas?

- Use appropriate attachments, such as rock buckets or augers designed for the specific conditions.

- Adjust the digging angle and speed to minimize resistance and avoid damage to the machine.

- Employ excavation techniques, such as benching or dewatering, to overcome obstacles.

- Consult with experienced operators or engineers for guidance and support.

7. Describe a time when you had to work closely with other team members on a digging project. How did you ensure effective communication and collaboration?

- Established clear communication channels for timely updates and instructions.

- Held regular briefings to discuss plans, progress, and potential issues.

- Provided guidance and support to less experienced team members.

- Coordinated actions to optimize efficiency and minimize disruptions.

- Maintained a positive and respectful work environment.

8. How do you stay up-to-date with advancements in digging machine technology and best practices?

- Attend industry conferences and workshops.

- Read trade publications and online forums.

- Consult with manufacturers and equipment suppliers.

- Participate in training and certification programs.

- Seek feedback from experienced operators and supervisors.

9. What strategies do you employ to minimize environmental impact and ensure sustainability in your digging operations?

- Use environmentally friendly fuels and lubricants.

- Recycle and dispose of waste materials responsibly.

- Control noise and dust emissions to minimize disturbance to nearby communities.

- Protect sensitive ecosystems and minimize soil erosion.

- Comply with all environmental regulations and guidelines.

10. Describe your experience in using GPS or laser guidance systems on digging machines. How have these technologies enhanced your productivity and accuracy?

- Increased precision and reduced the need for manual measurements.

- Automated excavation processes, saving time and labor costs.

- Improved coordination with other machines and teams.

- Minimized rework and ensured compliance with project specifications.

- Enhanced safety by providing real-time data on machine position and obstacles.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Digging Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Digging Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Digging Machine Operators are responsible for operating and maintaining heavy machinery used in excavation and construction projects. They play a vital role in the preparation and development of land for various purposes. Their primary duties involve:

1. Equipment Operation

Operate digging machines, such as excavators, backhoes, and trenchers, to excavate soil, rock, and other materials.

- Control the machine’s movements, including digging, lifting, and positioning.

- Adjust machine settings to optimize performance and efficiency.

2. Site Preparation

Prepare and maintain work sites by clearing vegetation, removing obstacles, and leveling ground.

- Mark digging areas based on plans and specifications.

- Monitor work progress and ensure compliance with safety regulations.

3. Excavation and Trenching

Excavate trenches and foundations for construction projects, such as buildings, roads, and pipelines.

- Dig to specified depths and dimensions.

- Maintain proper grading and slope angles.

4. Backfilling and Compaction

Backfill excavated areas with soil or other materials and compact them to ensure stability.

- Operate compaction equipment to create a solid and level surface.

- Ensure proper drainage and prevent soil erosion.

Interview Preparation Tips

To ace an interview for a Digging Machine Operator position, candidates should consider the following tips and strategies:

1. Research the Company and Position

Thoroughly research the company and the specific position to gain a clear understanding of their operations, industry trends, and company culture. This demonstrates your interest and preparation.

2. Highlight Relevant Experience

Emphasize your experience operating digging machines and performing related tasks in previous roles. Quantify your accomplishments and provide specific examples to showcase your skills.

3. Demonstrate Safety Awareness

Understand and emphasize your commitment to safety protocols and regulations. Highlight your knowledge of best practices and your ability to operate equipment safely.

4. Physical Preparation

Digging Machine Operator is a physically demanding job. Be prepared to discuss your physical abilities and stamina, as well as any relevant certifications or training.

5. Practice Common Interview Questions

Prepare answers to common interview questions such as “Tell me about yourself,” “Why are you interested in this position,” and “Describe a challenging situation you faced as a Digging Machine Operator.”

6. Ask Informed Questions

Prepare thoughtful questions to ask the interviewer. This demonstrates your engagement and interest in the role and company.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Digging Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.