Are you gearing up for an interview for a Ditching Machine Engineer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Ditching Machine Engineer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

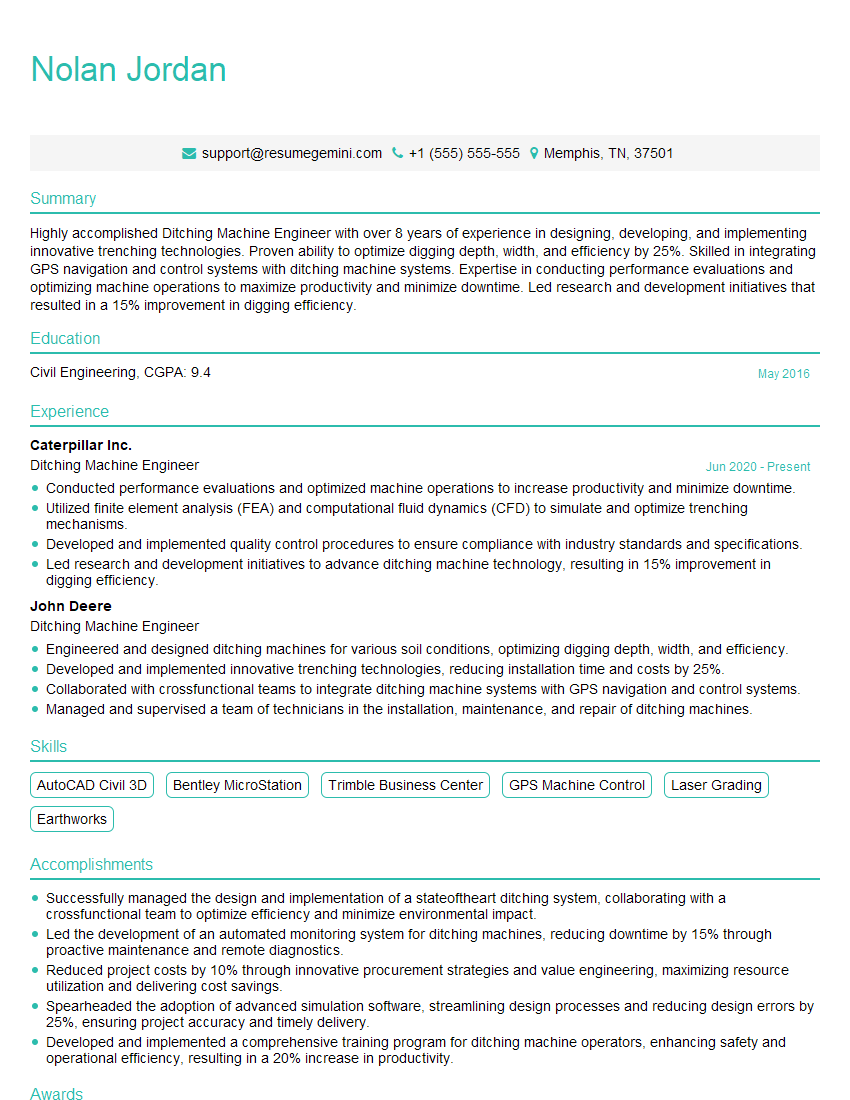

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ditching Machine Engineer

1. How would you design a ditching machine for a specific soil type?

- Begin by determining the soil’s properties, including texture, moisture content, and density.

- Select the appropriate blade shape and material based on the soil type. For example, cohesive soils require blades with a larger cutting edge, while non-cohesive soils can be handled by blades with a smaller cutting edge.

- Consider the depth and width of the ditch required, as well as the desired soil displacement.

- Design the machine’s frame and undercarriage to provide stability and durability in the specific soil conditions.

- Incorporate sensors and control systems to ensure precise depth control and minimize soil disturbance.

2. What are the key components of a ditching machine, and how do they interact?

Mechanical Components

- Prime mover (engine or motor)

- Transmission (converts engine power to usable torque)

- Blade (primary digging tool)

- Frame (supports the machine components)

- Undercarriage (wheels or tracks that provide mobility)

Control Systems

- Depth control system (maintains the desired ditch depth)

- Steering system (guides the machine along the desired path)

- Safety systems (protect operators and equipment from hazards)

Interaction

- The prime mover powers the transmission, which transfers power to the blade.

- The blade digs the ditch, and the soil is displaced by the blade’s cutting edge.

- The depth control system monitors the ditch depth and adjusts the blade’s position accordingly.

- The steering system guides the machine along the desired path, while the undercarriage provides stability and mobility.

3. How do you calculate the productivity of a ditching machine?

Productivity = (Ditch Length x Average Ditch Depth x Machine Speed) / Time

- Ditch Length: Total length of the ditch excavated (in meters or feet).

- Average Ditch Depth: Average depth of the ditch (in meters or feet).

- Machine Speed: Average speed at which the machine operates (in meters per minute or feet per minute).

- Time: Total time taken to excavate the ditch (in minutes or hours).

4. What are the different trenchless installation methods, and when would you recommend each method?

Trenchless Installation Methods

- Horizontal Directional Drilling (HDD)

- Microtunneling

- Pipe Bursting

- Plow-Based Installation

- Auger Boring

Method Recommendations

- HDD: Long distances, minimal ground disturbance, environmentally sensitive areas.

- Microtunneling: Smaller diameter pipes, urban areas, congested underground utilities.

- Pipe Bursting: Replacing old pipes, minimizing surface disruption.

- Plow-Based Installation: Shallow installations, greenfield areas.

- Auger Boring: Small-diameter installations, hard soil conditions.

5. How do you ensure the safety of ditching machine operators?

- Provide comprehensive training on machine operation and safety procedures.

- Implement proper machine maintenance and inspection schedules.

- Establish clear work zones and traffic management plans.

- Equip machines with safety features such as seat belts, rollover protection, and emergency stop buttons.

- Monitor operators and provide regular safety updates.

6. What are the environmental considerations when operating a ditching machine?

- Minimize soil erosion and sedimentation by implementing erosion control measures such as silt fences and straw bales.

- Protect wildlife and vegetation by avoiding sensitive areas and minimizing disturbance.

- Control noise and dust pollution by using appropriate equipment and mitigation measures.

- Dispose of waste materials, such as excavated soil and debris, in an environmentally responsible manner.

- Comply with all applicable environmental regulations and permits.

7. How do you troubleshoot common problems encountered in ditching machine operations?

- Clogged blade: Clean or replace the blade.

- Insufficient depth control: Check sensors, calibrate depth control system.

- Excessive vibration: Inspect and balance machine components, check for loose bolts.

- Hydraulic leaks: Identify the source of the leak and replace or repair seals.

- Engine problems: Perform engine diagnostics, check fuel levels and filters.

8. How do you stay up-to-date with the latest advancements in ditching machine technology?

- Attend industry conferences and exhibitions.

- Read technical journals and articles.

- Network with other engineers and professionals.

- Participate in online forums and discussion groups.

- Research and evaluate new technologies and equipment.

9. How do you work effectively as part of a team in a project environment?

- Communicate effectively and collaborate with team members.

- Share knowledge and expertise.

- Respect diverse perspectives and contribute to decision-making.

- Meet project deadlines and maintain high-quality standards.

- Provide support and assistance to colleagues.

10. How do you handle pressure and stress in a demanding work environment?

- Prioritize tasks and manage time effectively.

- Break down complex problems into smaller, manageable steps.

- Delegate responsibilities and seek support when needed.

- Take regular breaks and engage in stress-reducing activities.

- Maintain a positive attitude and focus on solutions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ditching Machine Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ditching Machine Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Ditching Machine Engineers are responsible for the design, development, and maintenance of ditching machines used in various industries such as agriculture, construction, and mining.

1. Design and Development

Collaborate with design engineers to develop new or improved ditching machines.

- Analyze customer requirements and translate them into design specifications.

- Perform calculations and simulations to optimize machine performance and efficiency.

2. Manufacturing and Assembly

Provide guidance and support during the manufacturing and assembly of ditching machines.

- Review manufacturing drawings and ensure quality control standards are met.

- Troubleshoot and resolve any issues during the assembly process.

3. Testing and Evaluation

Conduct thorough testing and evaluation of ditching machines to ensure they meet performance and safety requirements.

- Test machines under various conditions, such as different soil types and operating speeds.

- Analyze test results and make necessary modifications or adjustments.

4. Maintenance and Troubleshooting

Provide technical support to customers and operators for the maintenance and troubleshooting of ditching machines.

- Diagnose and resolve machine malfunctions and breakdowns.

- Provide training on proper machine operation and maintenance procedures.

Interview Tips

Preparing for a Ditching Machine Engineer interview can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Role

Thoroughly research the company and the specific Ditching Machine Engineer role you’re interviewing for.

- Visit the company’s website and social media pages to learn about their mission, values, and current projects.

- Review the job description carefully and identify key responsibilities and requirements.

2. Highlight Your Technical Expertise

Emphasize your technical skills and experience in design, manufacturing, and testing of ditching machines.

- Quantify your accomplishments and provide specific examples of your work.

- Showcase your knowledge of industry standards and best practices.

3. Demonstrate Your Problem-Solving Abilities

Interviewers are interested in candidates who can solve problems and make sound decisions.

- Share examples of challenges you’ve faced and the steps you took to overcome them.

- Explain your thought process and decision-making abilities.

4. Ask Thoughtful Questions

Asking insightful questions at the end of the interview shows your interest and engagement.

- Inquire about the company’s future projects and plans.

- Ask about the company’s commitment to innovation and research and development.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Ditching Machine Engineer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.