Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Dowel Pin Worker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Dowel Pin Worker so you can tailor your answers to impress potential employers.

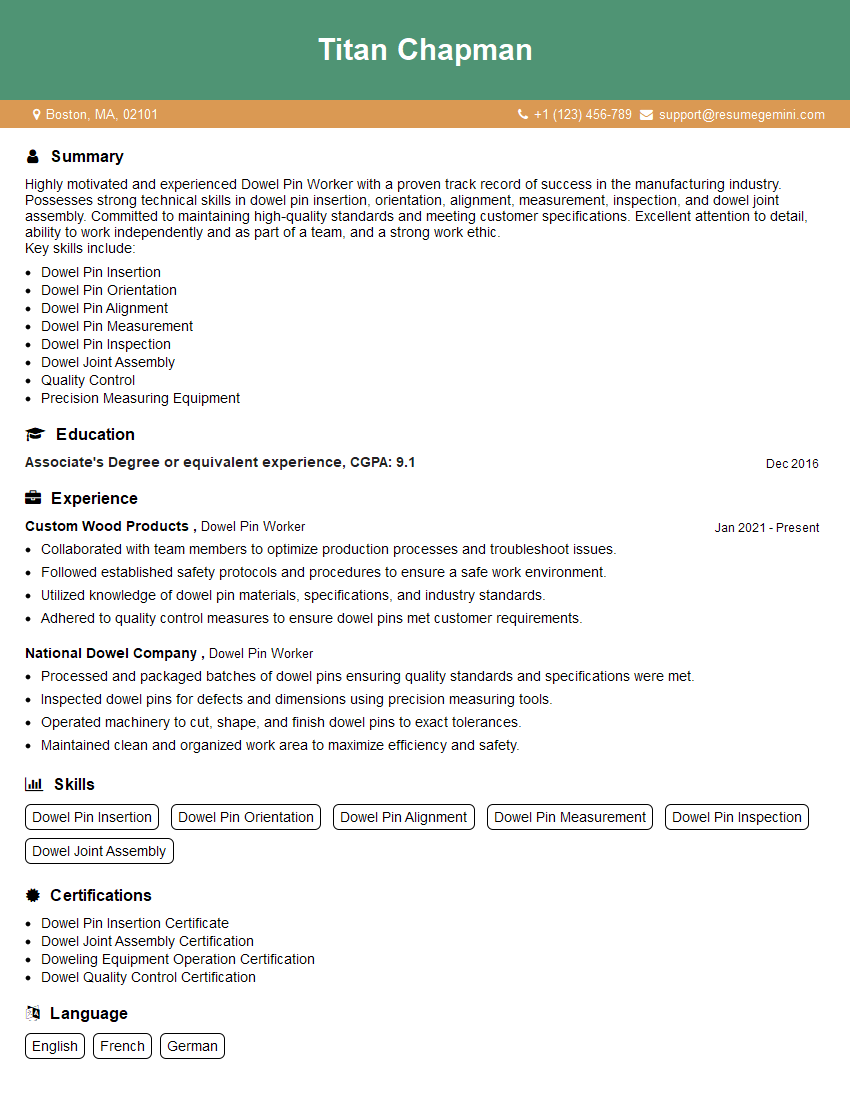

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dowel Pin Worker

1. What are the different types of dowel pins and their applications?

Dowel pins can be divided into several types based on their applications, including:

- Solid dowel pins: These are the most common type of dowel pins and are used for general purpose alignment and positioning of parts.

- Hollow dowel pins: These are made with a hollow center, which allows for the passage of fluids or wires.

- Tapered dowel pins: These have a tapered design, which makes them ideal for creating a secure fit in tapered holes.

- Spring dowel pins: These are designed with a spring-loaded action, which allows for easy insertion and removal.

2. What are the factors to consider when selecting the right dowel pin for a particular application?

Material

- Steel, stainless steel, and aluminum are the most commonly used materials.

- The strength, corrosion resistance, and weight of the pin should be considered.

Size

- The diameter and length of the pin must be appropriate for the size of the holes being joined.

- The length should be long enough to provide sufficient engagement with the mating part.

Tolerances

- The diameter and length of the pin should be within the specified tolerances for a proper fit.

- Tight tolerances are necessary for precision applications, while looser tolerances are acceptable for less critical applications.

3. What are the quality control procedures involved in the production of dowel pins?

Quality control procedures for dowel pins include:

- Dimensional inspection: The diameter, length, and tolerances are verified using measuring equipment.

- Material testing: The material is tested for strength, hardness, and corrosion resistance to ensure it meets specifications.

- Surface inspection: The surface of the pins is examined for any defects, such as scratches, cracks, or burrs.

- Functional testing: The pins are tested in actual applications to ensure they perform as expected.

4. What are the common problems that can occur during the production of dowel pins?

Common problems during dowel pin production include:

- Dimensional inaccuracies: Pins may not meet the specified dimensions due to improper machining or material shrinkage.

- Material defects: The material may contain flaws, such as inclusions, cracks, or voids, which can affect the strength of the pin.

- Surface imperfections: Scratches, burrs, or other surface defects can compromise the pin’s performance and appearance.

- Heat treatment issues: Improper heat treatment can alter the material properties and affect the pin’s strength and durability.

5. What are the recommended maintenance procedures for dowel pin machinery?

Regular maintenance is essential for optimal performance and longevity of dowel pin machinery. Recommended maintenance procedures include:

- Cleaning: Regularly cleaning the machinery to remove dust, debris, and lubricant build-up.

- Lubrication: Lubricating moving parts according to the manufacturer’s instructions to reduce friction and wear.

- Calibration: Calibrating the machinery periodically to ensure accurate measurements and consistent production.

- Inspection: Inspecting the machinery regularly for any signs of wear, damage, or malfunction.

6. What are the safety precautions that should be taken when working with dowel pin machinery?

Working with dowel pin machinery requires careful adherence to safety precautions, including:

- Proper attire: Wearing appropriate clothing, such as gloves and safety glasses, to protect against potential hazards.

- Machine guarding: Ensuring that all machine parts are properly guarded to prevent contact with moving components.

- Safe operation: Following proper operating procedures, including starting and stopping the machine safely.

- Emergency procedures: Knowing emergency stop procedures and evacuation routes in case of an incident.

- Regular training: Undergoing regular training to stay updated on safety protocols and best practices.

7. How do you ensure that the dowel pins produced meet the required quality standards?

To ensure the quality of dowel pins:

- Raw material inspection: Inspecting incoming raw materials to meet specifications.

- In-process inspections: Conducting inspections throughout the production process to identify and correct any deviations.

- Final inspection: Thoroughly inspecting finished dowel pins to verify their dimensions, surface finish, and other quality criteria.

- Testing: Performing functional tests or destructive tests to ensure the dowel pins meet performance requirements.

- Documentation: Maintaining detailed records of inspections and test results for traceability and quality assurance.

8. What are the latest advancements in dowel pin technology that you are aware of?

Recent advancements in dowel pin technology include:

- Advanced materials: Development of new materials with improved strength, wear resistance, and corrosion resistance.

- Optimized designs: Design improvements to enhance pin stability, reduce stress concentrations, and improve assembly efficiency.

- Automated inspection: Integration of automated inspection systems using image processing or non-destructive testing techniques.

- Additive manufacturing: Emerging use of additive manufacturing (3D printing) to produce custom dowel pins with complex geometries.

- Smart pins: Development of dowel pins with integrated sensors to monitor assembly conditions or provide additional functionality.

9. How do you stay updated with the latest industry trends and best practices related to dowel pin manufacturing?

I keep abreast of industry trends and best practices through:

- Conferences and exhibitions: Attending industry events to learn about new technologies, research findings, and market trends.

- Trade publications and journals: Subscribing to industry-specific publications and reading technical articles to stay informed about advancements.

- Online resources: Utilizing industry websites, forums, and social media platforms to connect with experts and access up-to-date information.

- Collaboration with partners: Engaging with suppliers, customers, and research institutions to exchange knowledge and explore innovative solutions.

10. What are your strengths and weaknesses as a Dowel Pin Worker?

Strengths

- Skilled in operating and maintaining dowel pin machinery.

- Expertise in dowel pin production processes and quality control techniques.

- Ability to work independently and as part of a team.

- Strong attention to detail and commitment to producing high-quality products.

Weaknesses

- Limited experience with certain specialized dowel pin technologies.

- Working in a fast-paced environment with tight deadlines can sometimes be challenging.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dowel Pin Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dowel Pin Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dowel Pin Workers perform a variety of tasks in the manufacturing process, contributing to the smooth operation of the production line. Their primary responsibilities include:

1. Dowel Pin Production

Operate dowel pin machines to manufacture dowel pins according to specifications.

- Set up and calibrate machines for specific dowel pin dimensions and tolerances.

- Monitor machines during operation, making adjustments to ensure consistent product quality.

2. Quality Control

Inspect dowel pins for compliance with quality standards and specifications.

- Visually inspect dowel pins for defects, such as cracks, burrs, or incorrect dimensions.

- Use measuring instruments (e.g., calipers, micrometers) to verify dimensional accuracy.

3. Material Handling

Move and handle raw materials, dowel pins, and finished products throughout the production area.

- Load and unload dowel pin machines with raw materials and finished products.

- Stack and store dowel pins in designated storage areas.

4. Machine Maintenance

Participate in basic maintenance and cleaning of dowel pin machines and equipment.

- Clean and lubricate machines to ensure optimal performance.

- Report any maintenance issues or equipment malfunctions to supervisors.

Interview Preparation Tips

To ace the interview for a Dowel Pin Worker position, candidates can follow these tips:

1. Research the Company and Position

Familiarize yourself with the company’s background, industry, and specific products or services.

- Visit the company’s website to gather information about their mission, values, and operations.

- Review the job description thoroughly to understand the responsibilities and qualifications required.

2. Highlight Relevant Skills and Experience

Emphasize your previous experience and skills that align with the job requirements.

- Provide specific examples of your ability to operate machinery, inspect products, and handle materials.

- Quantify your accomplishments whenever possible to demonstrate your impact (e.g., “Increased production efficiency by 15%”).

3. Practice Common Interview Questions

Prepare for common interview questions that you may encounter.

- Practice answering questions about your experience, skills, and motivation for applying.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your responses effectively.

4. Demonstrate Enthusiasm and Reliability

Convey your enthusiasm for the position and willingness to take on responsibilities.

- Express your interest in the company and industry and how you can contribute to their goals.

- Emphasize your strong work ethic and commitment to meeting deadlines and quality standards.

5. Prepare Questions to Ask the Interviewer

Asking well-thought-out questions at the end of the interview demonstrates your engagement and interest.

- Prepare questions about the company’s culture, growth opportunities, or specific responsibilities of the role.

- This shows that you are genuinely interested in the position and company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dowel Pin Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!