Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Drying Unit Felting Machine Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

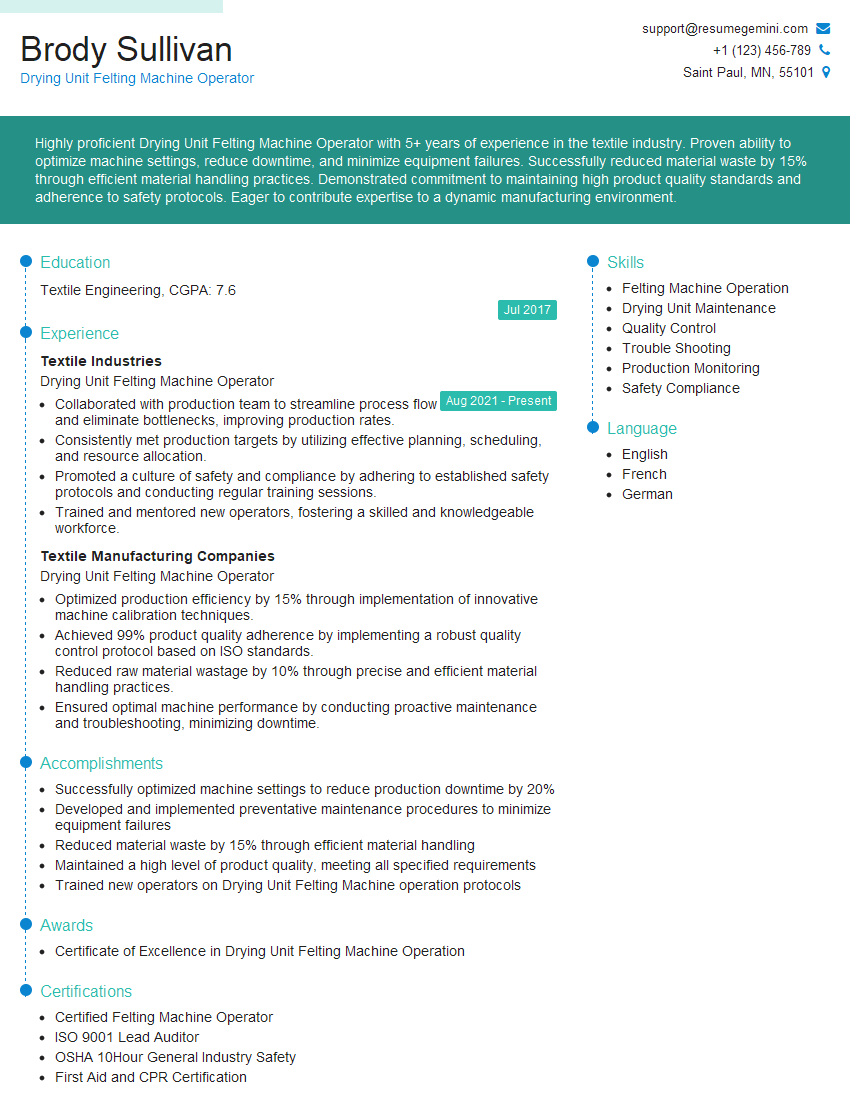

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Drying Unit Felting Machine Operator

1. Explain the process of felting in a textile manufacturing context.

- Felting is the process of interlocking and matting fibers together to create a non-woven fabric.

- This is achieved by applying heat, moisture, and agitation to fibers, causing them to tangle and form a cohesive structure.

2. How does a Drying Unit Felting Machine contribute to the felting process?

- It removes excess moisture from the felted fabric after the wet stages of the process.

- Drying is crucial to stabilize the fabric, improve its strength, and prevent shrinkage.

3. Describe the typical components of a Drying Unit Felting Machine.

- Heating chamber: Maintains a controlled temperature for drying.

- Conveyor belt: Transports the fabric through the heating chamber.

- Exhaust system: Removes moisture from the heating chamber.

- Sensors and controls: Monitor and regulate the temperature, moisture, and speed.

4. What are the optimal operating conditions for a Drying Unit Felting Machine to ensure efficient felting?

- Temperature: Varies depending on the fabric type and desired felting level.

- Moisture: The machine should remove enough moisture to prevent shrinkage but not over-dry the fabric.

- Speed: The speed of the conveyor belt should allow for adequate drying time.

- Airflow: Proper airflow is essential for removing moisture effectively.

5. How do you monitor the performance of a Drying Unit Felting Machine?

- Check the moisture content of the dried fabric.

- Observe the fabric’s surface quality and uniformity.

- Monitor the machine’s temperature settings and exhaust system’s efficiency.

- Review sensor readings and make necessary adjustments.

6. Describe a situation where you faced a challenge while operating a Drying Unit Felting Machine and how you resolved it.

- Challenge: Fabric shrinkage after drying due to over-drying.

- Resolution: Reduced the temperature and slowed down the conveyor belt speed to allow for gradual moisture removal.

7. What maintenance tasks are essential for a Drying Unit Felting Machine?

- Regular cleaning of the heating chamber and exhaust system.

- Checking and calibrating sensors to ensure accurate readings.

- Lubricating moving parts to prevent wear and tear.

- Inspecting belts and rollers for any damage or wear.

8. How do you prioritize safety measures when operating a Drying Unit Felting Machine?

- Wearing appropriate protective gear.

- Keeping the machine away from flammable materials.

- Ensuring proper ventilation.

- Following lockout/tagout procedures when performing maintenance.

9. Describe your experience with different felting techniques.

- Explain the advantages and disadvantages of wet felting, needle felting, and thermal bonding.

- Highlight any unique applications or projects you have worked on involving various felting techniques.

10. How do you stay up-to-date with the latest advancements in felting technology?

- Attend industry conferences and workshops.

- Read trade publications and research articles.

- Network with fellow professionals.

- Participate in continuous professional development programs.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Drying Unit Felting Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Drying Unit Felting Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Drying Unit Felting Machine Operator plays a crucial role in ensuring the optimal functioning of the drying unit and the production of high-quality felted products. The key responsibilities of this position include:

1. Machine Operation

Operate and maintain the drying unit felting machine, ensuring its smooth and efficient operation.

- Configure and adjust machine settings to meet production requirements.

- Monitor machine performance and make necessary adjustments to optimize output.

2. Raw Material Handling

Handle and prepare raw materials for the felting process.

- Inspect raw materials for quality and compliance.

- Load and unload materials onto the machine according to specifications.

3. Process Control and Monitoring

Control and monitor the felting process to ensure product quality.

- Monitor temperature, humidity, and other process parameters.

- Adjust settings as needed to maintain the desired product specifications.

4. Product Inspection and Quality Control

Inspect finished products to ensure they meet quality standards.

- Visually inspect products for defects or imperfections.

- Conduct quality control tests to verify product properties.

5. Maintenance and Troubleshooting

Perform routine maintenance and troubleshooting to keep the machine in good working condition.

- Clean and lubricate machine components.

- Diagnose and resolve mechanical or electrical issues.

6. Reporting and Recordkeeping

Maintain accurate records and report production data.

- Document production outputs, machine settings, and maintenance activities.

- Communicate any issues or deviations to supervisors promptly.

Interview Preparation Tips

To ace your interview for the Drying Unit Felting Machine Operator position, consider the following preparation tips:

1. Research the Company and Position

Familiarize yourself with the company’s profile, mission, and values. Research the industry and the specific responsibilities of the Drying Unit Felting Machine Operator role.

2. Highlight Relevant Experience and Skills

In your resume and during the interview, emphasize your experience in operating and maintaining machinery, handling raw materials, and conducting quality control. Showcase your problem-solving and analytical skills.

3. Practice Common Interview Questions

Anticipate common interview questions and prepare your answers accordingly. Practice articulating your strengths, weaknesses, and suitability for the role. Some example questions to practice include:

- Tell us about your experience in operating and maintaining drying unit felting machines?

- How do you ensure product quality during the felting process?

- Describe a situation where you successfully diagnosed and resolved a machine issue.

- How do you handle multiple tasks and prioritize your responsibilities?

- Why are you interested in working for our company?

4. Be Ready to Discuss Safety Procedures

As safety is crucial in manufacturing environments, be prepared to discuss your knowledge of and adherence to safety protocols and emergency procedures.

5. Ask Insightful Questions

At the end of the interview, ask thoughtful questions that demonstrate your interest in the position and the company. This shows that you are engaged and invested in the opportunity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Drying Unit Felting Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!