Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Dye Maker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Dye Maker so you can tailor your answers to impress potential employers.

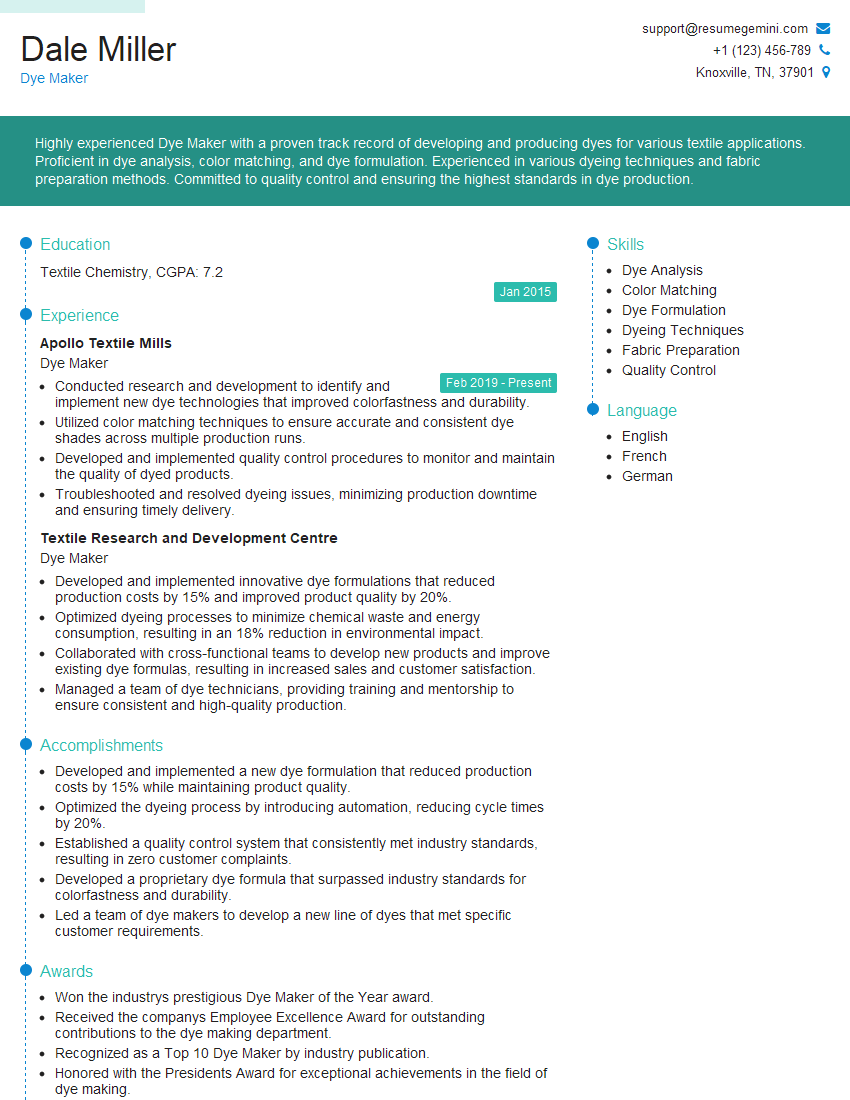

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dye Maker

1. What are the different types of dyes used in the textile industry?

The textile industry uses a wide range of dyes, each with its own unique properties and applications. Some of the most common types of dyes include:

- Acid dyes are used to dye wool, silk, and nylon.

- Direct dyes are used to dye cotton, linen, and rayon.

- Disperse dyes are used to dye synthetic fibers such as polyester and nylon.

- Reactive dyes are used to dye cotton and other cellulosic fibers.

- Sulfur dyes are used to dye cotton and other natural fibers.

- Vat dyes are used to dye cotton and other natural fibers.

2. What are the key factors to consider when selecting a dye for a particular application?

Factors to consider:

- Fiber type: Different fibers have different affinities for different types of dyes.

- Dye color: The desired color of the dyed product.

- Fastness requirements: The dye must be able to withstand the intended use of the dyed product, such as washing, sunlight, and abrasion.

- Cost: The cost of the dye and the dyeing process.

- Environmental impact: The environmental impact of the dye and the dyeing process.

3. What are the different methods of applying dyes to textiles?

There are a variety of methods for applying dyes to textiles, including:

- Dyeing: The fabric is immersed in a dye solution and heated to allow the dye to penetrate the fibers.

- Printing: Dye is applied to the fabric using a printing machine, which creates a design or pattern.

- Spraying: Dye is sprayed onto the fabric using a spray gun.

- Padding: The fabric is passed through a padder, which applies a thin layer of dye to the surface of the fabric.

- Coating: The fabric is coated with a thin layer of dye, which is then dried and cured.

4. What are the most common problems encountered in dyeing textiles?

Some of the most common problems encountered in dyeing textiles include:

- Color bleeding: The dye may bleed from the dyed fabric onto other fabrics or materials.

- Crocking: The dye may rub off from the dyed fabric onto other fabrics or materials.

- Fading: The dye may fade over time due to exposure to sunlight or washing.

- Staining: The dye may stain the fabric with an unwanted color.

- Shrinkage: The fabric may shrink during the dyeing process.

5. What are the latest trends in textile dyeing?

Some of the latest trends in textile dyeing include:

- Sustainable dyeing: The use of dyes and dyeing processes that are environmentally friendly.

- Digital printing: The use of digital printing technology to create designs and patterns on fabrics.

- 3D printing: The use of 3D printing technology to create three-dimensional objects from fabrics.

- Nanotechnology: The use of nanotechnology to create new dyes and dyeing processes.

- Smart textiles: The use of dyes and dyeing processes to create fabrics with special properties, such as antibacterial or UV-resistant properties.

6. What are the safety precautions that must be taken when working with dyes?

When working with dyes, it is important to take the following safety precautions:

- Wear appropriate protective clothing: This includes gloves, goggles, and a lab coat.

- Work in a well-ventilated area: Dyes can release harmful fumes.

- Avoid contact with skin and eyes: Dyes can cause skin and eye irritation.

- Do not ingest dyes: Dyes can be harmful if ingested.

- Dispose of dyes properly: Dyes should be disposed of according to local regulations.

7. What are the different types of dye defects?

There are a variety of dye defects that can occur, including:

- Bleeding: The dye may bleed from the dyed fabric onto other fabrics or materials.

- Crocking: The dye may rub off from the dyed fabric onto other fabrics or materials.

- Fading: The dye may fade over time due to exposure to sunlight or washing.

- Staining: The dye may stain the fabric with an unwanted color.

- Shrinkage: The fabric may shrink during the dyeing process.

- Uneven dyeing: The dye may not be evenly distributed throughout the fabric.

8. What are the causes of dye defects?

Dye defects can be caused by a variety of factors, including:

- Improper dye selection: The dye may not be compatible with the fiber type or the dyeing process.

- Improper dyeing conditions: The temperature, pH, and time of the dyeing process may not be correct.

- Improper drying conditions: The fabric may not be properly dried after dyeing, which can cause the dye to bleed or fade.

- Mechanical damage: The fabric may be damaged during the dyeing process, which can cause the dye to bleed or fade.

- Chemical contamination: The dye may be contaminated with other chemicals, which can cause the dye to bleed or fade.

9. How can dye defects be prevented?

Dye defects can be prevented by taking the following steps:

- Select the correct dye: The dye should be compatible with the fiber type and the dyeing process.

- Use the correct dyeing conditions: The temperature, pH, and time of the dyeing process should be correct.

- Dry the fabric properly: The fabric should be properly dried after dyeing to prevent the dye from bleeding or fading.

- Avoid mechanical damage: The fabric should be handled carefully during the dyeing process to avoid damage.

- Inspect the fabric: The fabric should be inspected after dyeing to identify any defects.

10. What are the different types of dye testing?

There are a variety of dye tests that can be performed to evaluate the quality of the dye and the dyeing process, including:

- Colorfastness testing: This test evaluates the resistance of the dye to fading, bleeding, and crocking.

- Shrinkage testing: This test evaluates the amount of shrinkage that occurs during the dyeing process.

- pH testing: This test evaluates the pH of the dyeing solution.

- Spectrophotometer testing: This test evaluates the color of the dyed fabric.

- Gas chromatography-mass spectrometry (GC-MS): This test evaluates the chemical composition of the dye.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dye Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dye Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Dye Makers are responsible for creating and maintaining the desired colors in fabrics and other materials. They follow specific instructions to create the perfect shade and intensity for products, ensuring that the final product meets the expected standards.

1. Creating and Mixing Dyes

Dye Makers create and mix dyes according to specific formulas and instructions.

- Calculate and weigh ingredients accurately to achieve desired color and shade.

- Operate and maintain dyeing equipment, including mixing tanks, dyeing machines, and automated systems.

2. Dyeing Techniques

Dye Makers use various dyeing techniques to apply color to fabrics or other materials.

- Immersion dyeing – Submerging materials in dye baths.

- Spray dyeing – Applying dyes using spray guns.

- Screen printing – Printing designs using stencils and dyes.

3. Color Matching

Dye Makers match colors precisely according to customer specifications or industry standards.

- Use spectrophotometers to analyze colors and ensure accuracy.

- Adjust dye formulations to achieve the desired color match.

4. Quality Control

Dye Makers ensure the quality of dyed materials by conducting inspections and tests.

- Inspect dyed materials for color uniformity, shade consistency, and fastness.

- Conduct tests to assess dye penetration, colorfastness to light, and washing durability.

Interview Tips

Preparing thoroughly for a Dye Maker interview will significantly boost your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Take the time to research the company you’re applying to and the specific Dye Maker position. Understand their products, services, and values. This knowledge will help you tailor your answers to the interviewer’s questions and demonstrate your interest in the role.

2. Highlight Your Skills and Experience

Emphasize your skills and experience that are relevant to the Dye Maker position. Quantify your accomplishments whenever possible, using specific examples to illustrate your contributions. For instance, you could mention a project where you successfully matched a complex color or implemented a new dyeing technique that improved efficiency.

3. Showcase Your Color Expertise

Dye Makers are expected to have a strong understanding of colors and their interactions. Discuss your knowledge of color theory, including concepts like the color wheel, primary and secondary colors, and color matching techniques. You can also mention any experience you have with spectrophotometers or other color analysis equipment.

4. Prepare for Technical Questions

Be prepared to answer technical questions related to dyeing processes, equipment, and quality control. Review the basics of dyeing chemistry, different types of dyes, and the factors that affect dye penetration and fastness. You may also be asked about your experience with specific dyeing techniques or equipment.

5. Practice Your Communication Skills

Technical skills are essential, but strong communication skills are just as important. Practice answering interview questions clearly and concisely. Be prepared to articulate your ideas, explain your thought process, and ask questions to clarify the interviewer’s expectations.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dye Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!