Are you gearing up for an interview for a Dye Mixer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Dye Mixer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

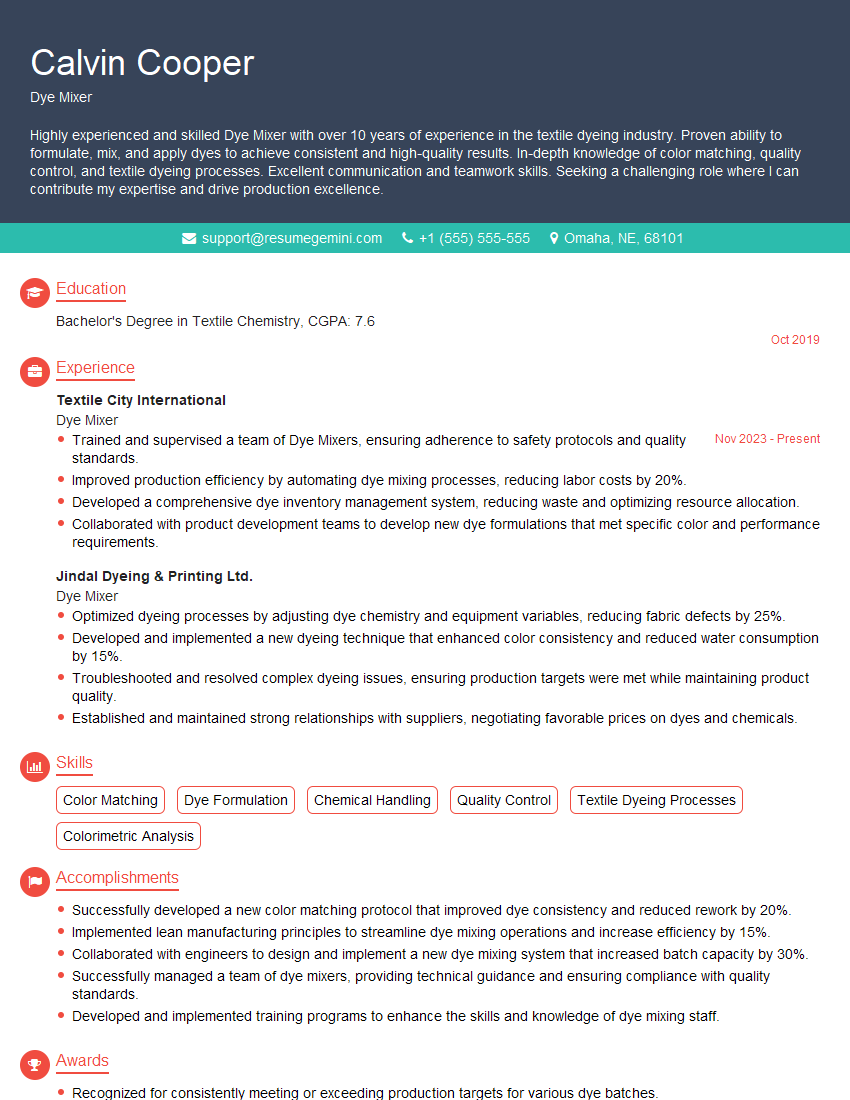

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Dye Mixer

1. How do you ensure the accuracy of the color matching process?

- Describe the equipment and techniques used for color measurement, such as spectrophotometers or colorimeters.

- Explain the calibration and maintenance procedures followed to ensure the accuracy of the instruments.

- Mention any quality control measures implemented to verify the consistency of the color matches.

2. What are the different types of dyes you have experience working with?

Acid Dyes:

- Briefly explain the characteristics and applications of acid dyes, such as their affinity for wool and nylon.

- Discuss any specific precautions or handling procedures required.

Basic Dyes:

- Describe the properties and uses of basic dyes, focusing on their suitability for cotton and other cellulosic fibers.

- Mention any safety considerations associated with handling basic dyes.

Direct Dyes:

- Explain the advantages and limitations of direct dyes, highlighting their ease of application and affinity for cellulose fibers.

- Discuss the potential challenges or precautions required when using direct dyes.

3. How do you handle dye lot variations and maintain dye consistency?

- Explain the importance of lot testing and how it helps ensure dye consistency.

- Describe the steps involved in evaluating dye lot variations, such as shade, strength, and fastness properties.

- Discuss any strategies or techniques used to minimize variations and maintain consistent dye results.

4. What are the key factors that affect the quality of the dyeing process?

- Discuss the role of factors such as pH, temperature, dye concentration, and auxiliary chemicals in the dyeing process.

- Explain how variations in these factors can impact the colorfastness, shade, and overall quality of the dyed fabric.

- Describe any monitoring or control measures implemented to ensure optimal dyeing conditions.

5. How do you troubleshoot common problems encountered in the dyeing process?

- Identify common issues such as uneven dyeing, streaks, or shade variations.

- Explain the potential causes and solutions for each problem, focusing on the specific technical knowledge required to resolve them.

- Describe any corrective actions or adjustments made to optimize the dyeing process and prevent future occurrences.

6. What are the safety precautions you observe when handling dyes and chemicals?

- Discuss the importance of proper personal protective equipment (PPE), such as gloves, masks, and protective clothing.

- Explain the potential hazards of working with dyes and chemicals, including allergic reactions, respiratory issues, or environmental contamination.

- Describe the procedures followed for handling, storage, and disposal of dyes and chemical waste according to safety regulations.

7. How do you stay up-to-date with advancements in dyeing technology and techniques?

- Discuss the importance of continuous learning and professional development.

- Mention industry publications, conferences, or training programs attended to enhance knowledge and skills.

- Explain how staying informed about new techniques and equipment helps improve dye application and overall process efficiency.

8. How do you ensure the sustainability of the dyeing process?

- Discuss the use of environmentally friendly dyes and chemicals.

- Explain the implementation of water conservation measures and waste reduction techniques.

- Mention any industry certifications or standards followed for sustainable dyeing practices.

9. What are the different methods of dye application and their advantages/disadvantages?

- Explain the methods such as exhaust dyeing, package dyeing, and continuous dyeing.

- Discuss the suitability of each method based on fiber type, dye properties, and production scale.

- Highlight the advantages and limitations of each method, considering factors like cost, efficiency, and quality.

10. Describe your experience in shade matching and color correction.

- Explain the process of shade matching, including the use of color standards and spectrophotometers.

- Discuss the techniques used to adjust dye formulas and troubleshoot color deviations.

- Provide examples of successful color correction projects handled and the strategies employed to achieve accurate color outcomes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Dye Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Dye Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Dye Mixer is responsible for the preparation and mixing of dyes, chemicals, and other additives used in the production of textiles, paints, and other products. They work in a variety of industries, including manufacturing, textiles, and automotive.

1. Dye Preparation

Dye Mixers typically start their day by preparing dyes according to specified formulas. This may involve measuring out the correct amounts of powder, liquid, or paste dyes and mixing them with water or other solvents.

- Measure and mix dyes according to recipes and specifications

- Add chemicals and additives to dyes to achieve desired color and properties.

2. Dye Mixing

Once the dyes are prepared, the Dye Mixer will mix them to create the desired shade or color. This may involve using a variety of techniques, such as stirring, blending, or using a machine.

- Mix dyes to achieve uniform colors and consistency

- Adjust dye concentrations to meet color specifications

3. Quality Control

Dye Mixers also perform quality control checks on the dyes they produce. This may involve testing the color, pH, and viscosity of the dyes to ensure that they meet the specifications.

- Monitor dye quality by conducting tests on samples

- Adjust dye formulas and processes to correct any deviations

4. Equipment Maintenance

Dye Mixers are also responsible for maintaining the equipment they use. This may involve cleaning, calibrating, and repairing equipment to ensure that it is functioning properly.

- Clean and maintain dye mixing equipment

- Calibrate and adjust equipment to ensure accurate mixing

Interview Tips

Here are some tips to help you ace your interview for a Dye Mixer position:

1. Research the Company and the Position

Before you go on your interview, it is important to research the company and the position you are applying for. This will help you understand the company’s culture, values, and what they are looking for in a Dye Mixer.

- Visit the company’s website

- Read the job description carefully

- Talk to people who work in the industry

2. Practice Your Answers to Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is helpful to practice answering these questions ahead of time so that you can feel confident and prepared during your interview.

- Consider common interview questions

- Prepare your answers to them

- Rehearse your answers out loud

3. Be Prepared to Talk About Your Experience

The interviewer will be interested in your experience as a Dye Mixer. Be prepared to talk about your skills and knowledge, and how they relate to the requirements of the position.

- Highlight your relevant skills and experience.

- Use specific examples to demonstrate your abilities.

- Quantify your results whenever possible.

4. Be Professional and Enthusiastic

First impressions matter, so it is important to be professional and enthusiastic during your interview. Dress appropriately, arrive on time, and be polite to everyone you meet.

- Dress professionally for the interview.

- Arrive on time for your interview.

- Be polite and respectful to everyone you meet.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Dye Mixer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!