Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Ear Pull Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Ear Pull Machine Operator so you can tailor your answers to impress potential employers.

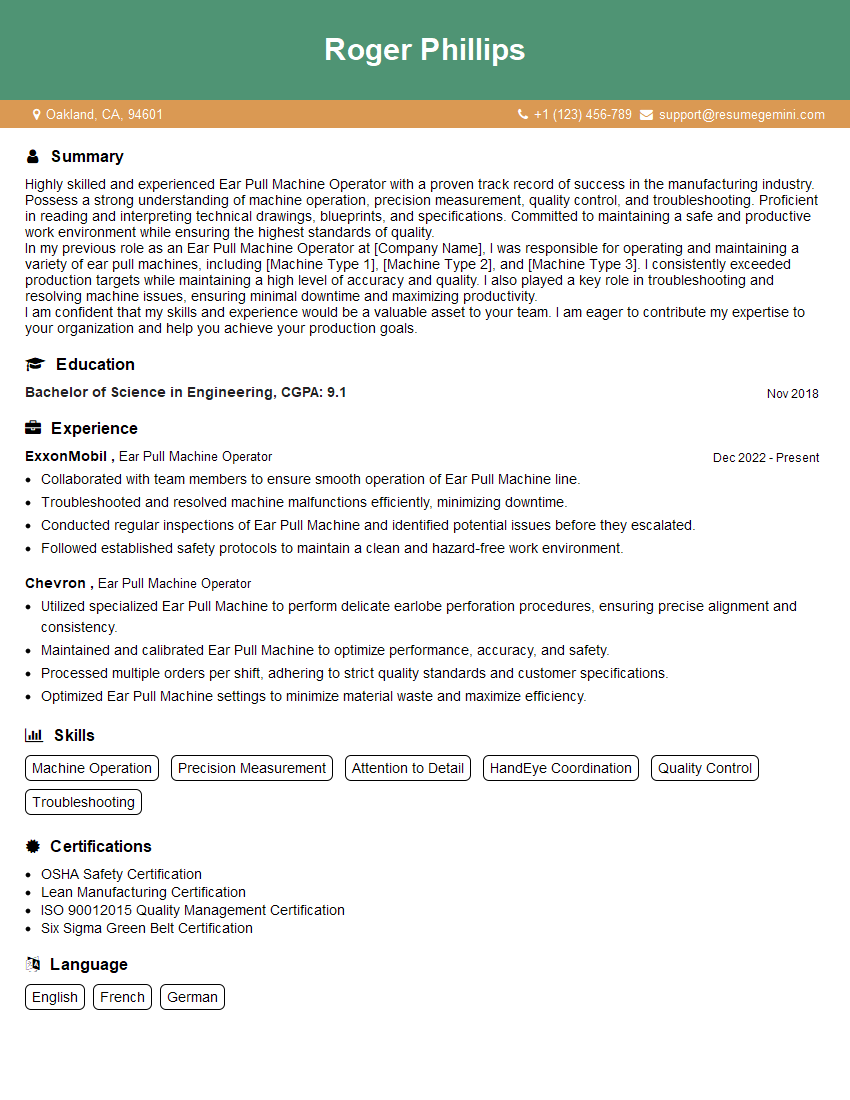

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ear Pull Machine Operator

1. What are the main responsibilities of an Ear Pull Machine Operator?

- Operate and maintain ear pull machines to produce various earpieces.

- Monitor machine functions, ensure product quality, and troubleshoot issues.

- Inspect and clean machines regularly to ensure optimal performance.

- Follow safety protocols and maintain a safe working environment.

- Coordinate with other team members to ensure smooth production flow.

2. Describe the different types of ear pull machines you’ve worked with and their respective functions.

Manual Ear Pull Machine

- Manually operated machine used for small-scale production.

- Requires precise hand-eye coordination to pull material evenly.

Semi-Automatic Ear Pull Machine

- Automated machine that performs most tasks, reducing human intervention.

- Reduces manual labor and increases production efficiency.

Fully Automatic Ear Pull Machine

- Highly advanced machine that automates the entire process.

- Automates material feeding, pulling, and molding.

3. How do you ensure the quality of earpieces produced by the machine?

- Regularly perform machine calibration and maintenance.

- Inspect incoming materials for defects.

- Monitor the pulling process to ensure consistent material tension.

- Conduct visual inspections of finished earpieces.

- Use quality control tools, such as gauges and calipers, to ensure dimensional accuracy.

4. How do you troubleshoot common issues encountered with ear pull machines?

- Material breakage: Check for excessive pulling force or worn dies.

- Inconsistent material tension: Adjust machine settings or replace worn parts.

- Irregular earpiece shape: Check for alignment issues or machine malfunctions.

- Damaged machine parts: Identify and replace worn or damaged components.

- Electrical problems: Check for loose connections or faulty electrical components.

5. What safety precautions do you take when operating an ear pull machine?

- Wear appropriate safety gear, including gloves and safety glasses.

- Ensure the machine is properly grounded.

- Keep the work area clean and free of debris.

- Follow lock-out/tag-out procedures before performing maintenance.

- Be aware of potential hazards and take necessary precautions.

6. How do you handle production targets and meet deadlines?

- Prioritize tasks based on urgency and importance.

- Maximize machine uptime by performing regular maintenance.

- Collaborate with other team members to optimize workflow.

- Communicate any potential delays or challenges to supervisors.

- Stay informed about production schedules and adjust accordingly.

7. What is your experience with different types of materials used in earpiece production?

- Silicone: Flexible and hypoallergenic, suitable for custom-fit earpieces.

- Acrylic: Durable and resistant to damage, often used for hearing aids.

- Vinyl: Cost-effective option, commonly used for disposable earpieces.

- Polyethylene: Stretchable and comfortable, used for in-ear monitors.

- Polycarbonate: Strong and lightweight, suitable for high-end earpieces.

8. How do you maintain accurate records and documentation related to earpiece production?

- Maintain a production logbook to record machine settings, material used, and quality control results.

- Use electronic data management systems to store and access production data.

- Ensure traceability by linking raw material batches to finished earpieces.

- Archive production records for compliance and traceability purposes.

- Follow established documentation procedures to provide accurate information.

9. What is your approach to continuous improvement in the ear pull machine operation process?

- Regularly identify areas for improvement through observation and data analysis.

- Implement process modifications to enhance efficiency and reduce waste.

- Suggest new techniques or technologies to improve machine performance.

- Participate in training and development opportunities to enhance skills.

- Seek feedback from supervisors and colleagues to identify potential improvements.

10. How do you stay up-to-date with advancements in ear pull machine technology?

- Attend industry events and conferences.

- Read technical publications and white papers.

- Network with professionals in the field.

- Consult with equipment manufacturers.

- Pursue continuing education opportunities.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ear Pull Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ear Pull Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Ear Pull Machine Operator plays a vital role in the production process, by operating the ear pull machine to extract corn from the cob. They are responsible for ensuring the efficient and productive operation of the machine to meet production targets.

1. Machine Operation

• Operate the ear pull machine following established procedures and safety guidelines.

• Monitor the machine’s performance, ensuring smooth operation and identifying potential issues.

• Adjust machine settings to optimize performance and minimize downtime.

2. Maintenance and Repairs

• Perform routine maintenance tasks on the ear pull machine, including cleaning, lubrication, and minor repairs.

• Identify and report any major issues or breakdowns to the supervisor or maintenance team.

3. Quality Control

• Inspect corn ears before and after processing to ensure quality standards are met.

• Remove any damaged or defective corn ears to prevent contamination or product loss.

4. Production Monitoring and Reporting

• Monitor production output and ensure it meets or exceeds targets.

• Record and report production data, including quantities processed and downtime.

Interview Tips

Preparing for an interview can significantly improve your chances of success. Here are some essential interview tips:

1. Research the Company and Position

• Familiarize yourself with the company’s website, industry, and job description.

• Research the specific responsibilities and qualifications required for the Ear Pull Machine Operator role.

2. Practice Common Interview Questions

• Prepare answers to common interview questions related to your experience, skills, and qualifications.

• Consider using the STAR method (Situation, Task, Action, Result) to structure your responses.

3. Highlight Relevant Skills and Experience

• Emphasize your proficiency in operating ear pull machines and your attention to detail.

• Share examples of your problem-solving and troubleshooting abilities.

4. Demonstrate Your Passion and Enthusiasm

• Express your interest in the position and your passion for the food industry.

• Show the interviewer that you are eager to learn and contribute to the team.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Ear Pull Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.